Arrangement used for manufacturing large area micro-nano structure

A micro-nano structure and large-area technology, which is applied in the direction of photolithography, optics, and opto-mechanical equipment on the pattern surface, can solve the problems of difficulty in making nano-imprint templates, unsuitability for large-area structures, and inability to mass-produce. , to achieve the effects of low development cost, simple optical path adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

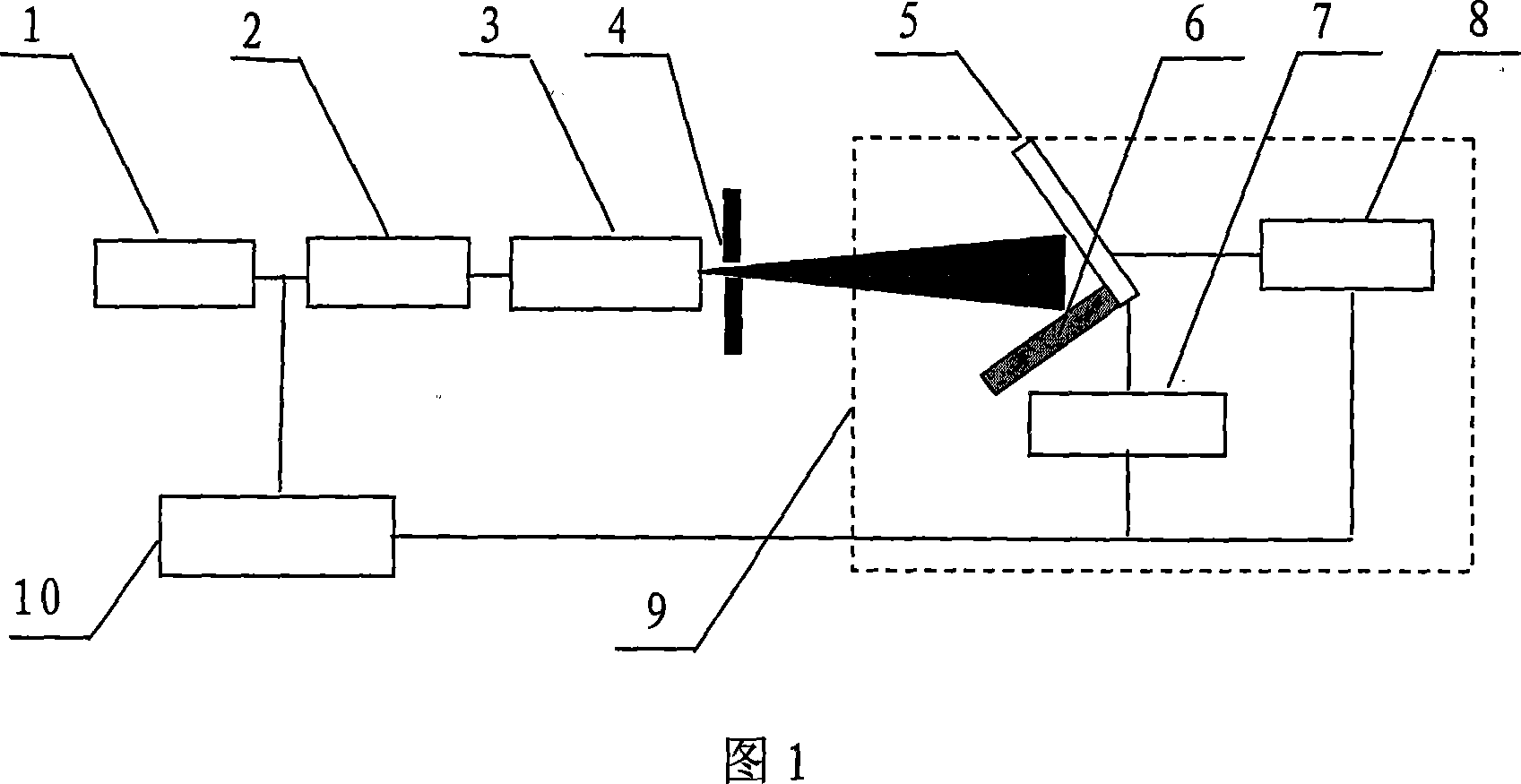

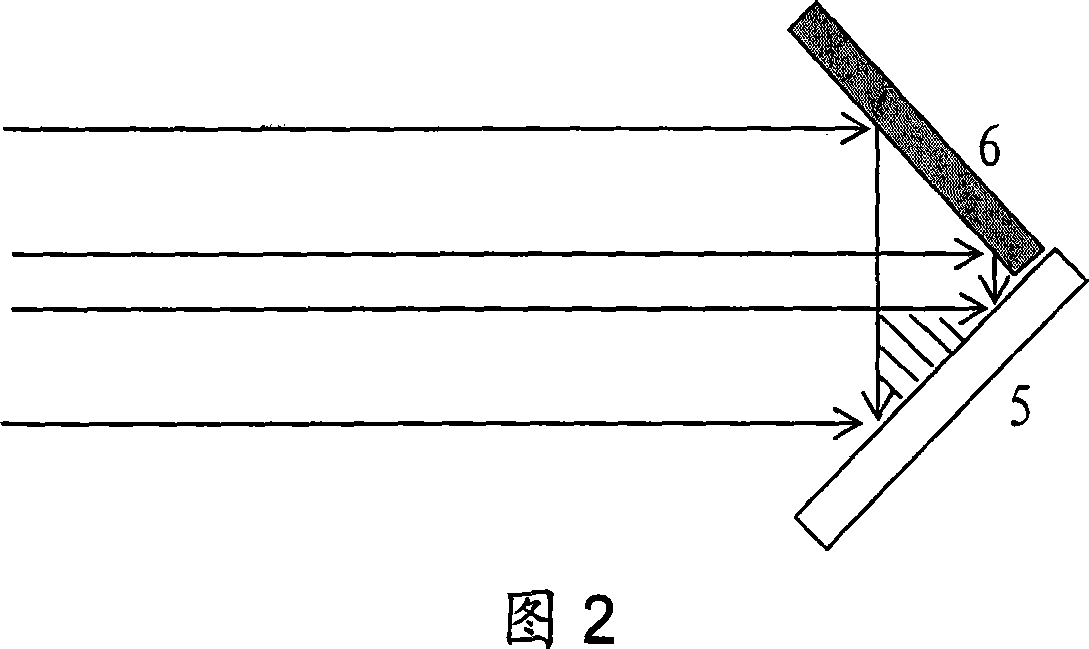

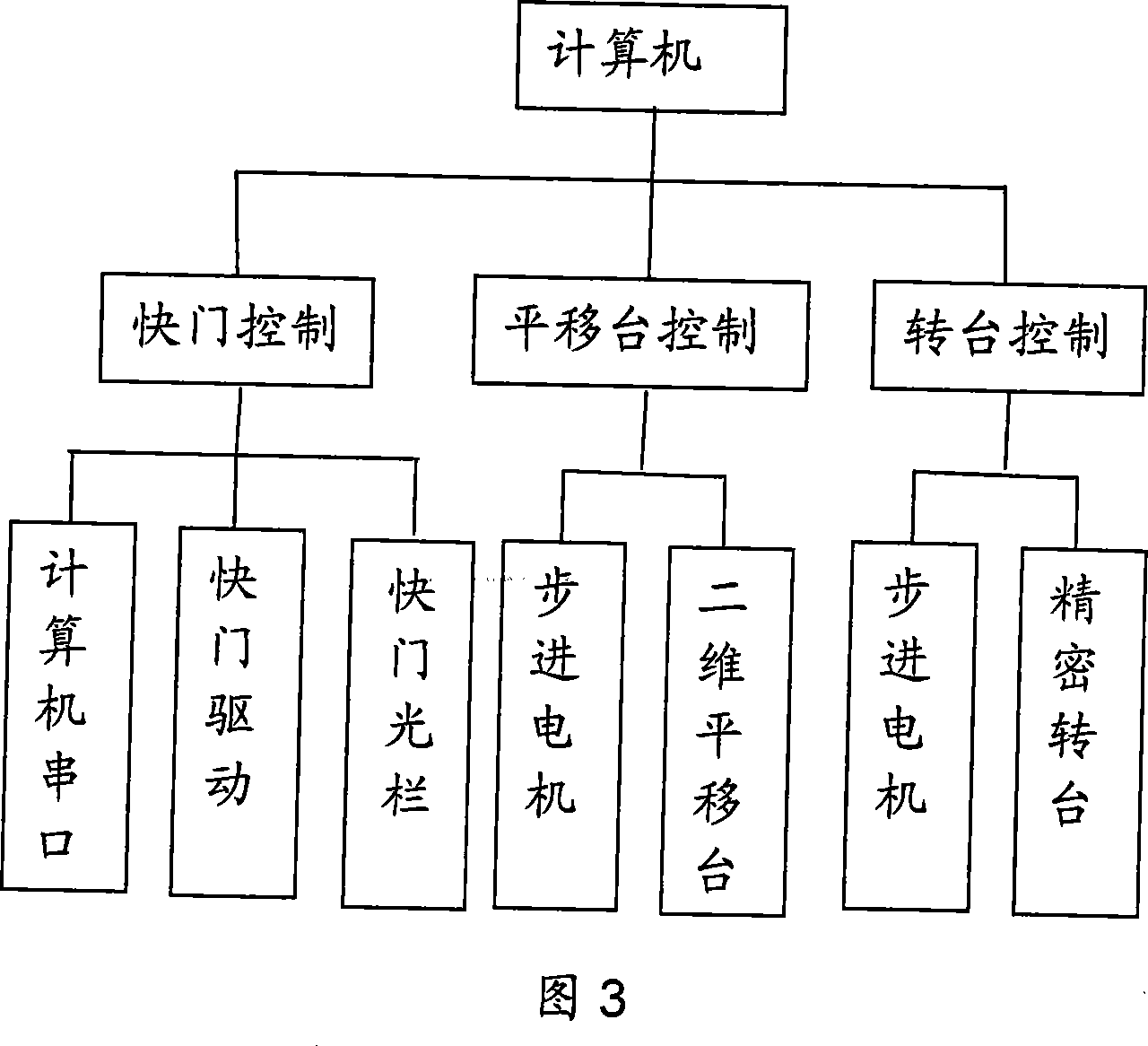

[0017] As shown in Figure 1, the present invention mainly comprises a coherent light source 1, a shutter 2, a spatial filter 3, an aperture 4, a sample stage 5, a mirror 6, a precision turntable 7, a two-dimensional translation stage 8, a local darkroom 9, and a computer. control system 10. The laser beam is emitted by a coherent light source 1, and enters the spatial filter 3 through the shutter 2 and mirror 6. After the spatial filter 3 improves the spatial coherence and beam uniformity, the stray light and the size of the beam are controlled by the diaphragm 4, and finally irradiated On mirror 6 and sample stage 5. The sample stage 5 is fixed on the two-dimensional translation stage 7 at first, and then it is vertically fixed on the precision turntable 7 together with the mirror 6 . The opening and closing of the shutter 2 , the movement of the two-dimensional translation platform 8 and the rotation of the precision turntable 7 are completed by the computer control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com