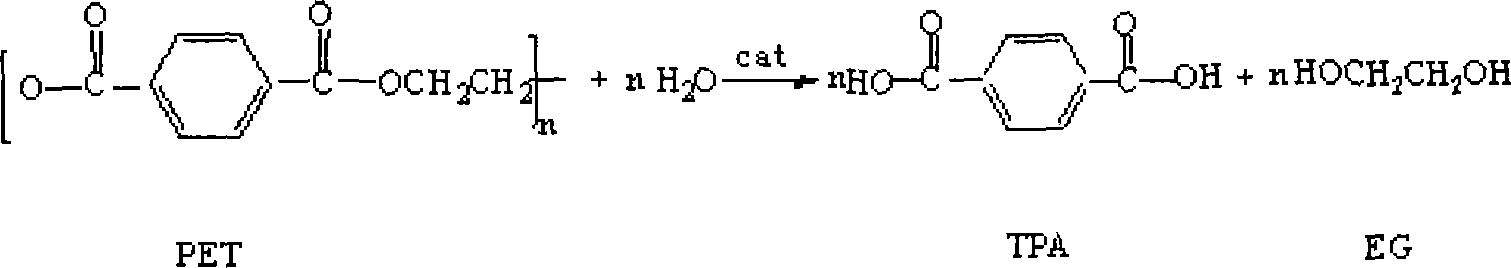

Catalytic depolymerization of PET under microwave irradiation

A microwave radiation, catalytic depolymerization technology, applied in chemical instruments and methods, organic chemistry, preparation of oxygenated compounds, etc., can solve problems such as harsh reaction conditions, and achieve the effects of mild reaction conditions, shortened reaction time, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0026] Put PET particles, water, and zinc acetate catalyst into the reactor, the weight ratio of PET and water is 1:10, and the weight ratio of zinc acetate catalyst is 0.6%; set the reaction temperature to 200°C, the reaction pressure to 1.0MPa, and the microwave power to 250W, after depolymerization for 200min, cool for 20min; filter the depolymerization product, and wash the solid with a small amount of deionized water (to remove a small amount of catalyst in the solid), dry the solid to constant weight; distill the filtrate to obtain the EG product; use 0.5mol / After the NaOH solution of 1 L is dissolved, add hydrochloric acid equivalent to the sodium ion, filter, wash with deionized water to remove the NaCl aqueous solution, and obtain a pure TPA solid, dry to obtain a white refined TPA solid product, and the PET depolymerization rate reaches 89.2 %.

experiment example 2

[0028] Put PET pellets, water, and manganese acetate catalyst into the reactor, the weight ratio of PET and water is 1:12, and the weight ratio of manganese acetate catalyst is 1.0%; set the reaction temperature to 200°C, the reaction pressure to 1.0MPa, and the microwave power to 250W, after depolymerization for 150min, cool for 20min; filter the depolymerization product, and wash the solid with a small amount of deionized water (remove a small amount of catalyst in the solid), dry the solid to constant weight; distill the filtrate to obtain the EG product; crude TPA with 0.5mol / After the NaOH solution of L is dissolved, add hydrochloric acid equivalent to the sodium ion, filter, wash with deionized water to remove the NaCl aqueous solution, obtain a pure TPA solid, dry it, and obtain a white refined TPA solid product, and the PET depolymerization rate reaches 70.5 %.

experiment example 3

[0030] Put PET pellets, water, and potassium oxalate catalyst into the reactor, the weight ratio of PET to water is 1:10, and the weight ratio of potassium oxalate catalyst is 1.5%; set the reaction temperature to 150°C, the reaction pressure to 1.0MPa, and the microwave power to 250W, after depolymerization for 150min, cool for 20min; filter the depolymerization product, and wash the solid with a small amount of deionized water (remove a small amount of catalyst in the solid), dry the solid to constant weight; distill the filtrate to obtain the EG product; crude TPA with 0.5mol / After the NaOH solution of L is dissolved, add hydrochloric acid equivalent to the sodium ion, filter, wash with deionized water to remove the NaCl aqueous solution, and obtain a pure TPA solid, dry to obtain a white refined TPA solid product, and the PET depolymerization rate reaches 65.2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com