Rare-earth-ion or transient metal ion doped scandium aluminium-magnesium-salt fluorescent lining base

A technology of transition metal ions and rare earth ions, which is applied in the fields of luminescent materials, semiconductor devices, chemical instruments and methods, etc., can solve the problem of ineffective doping of rare earth ions or transition metal ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

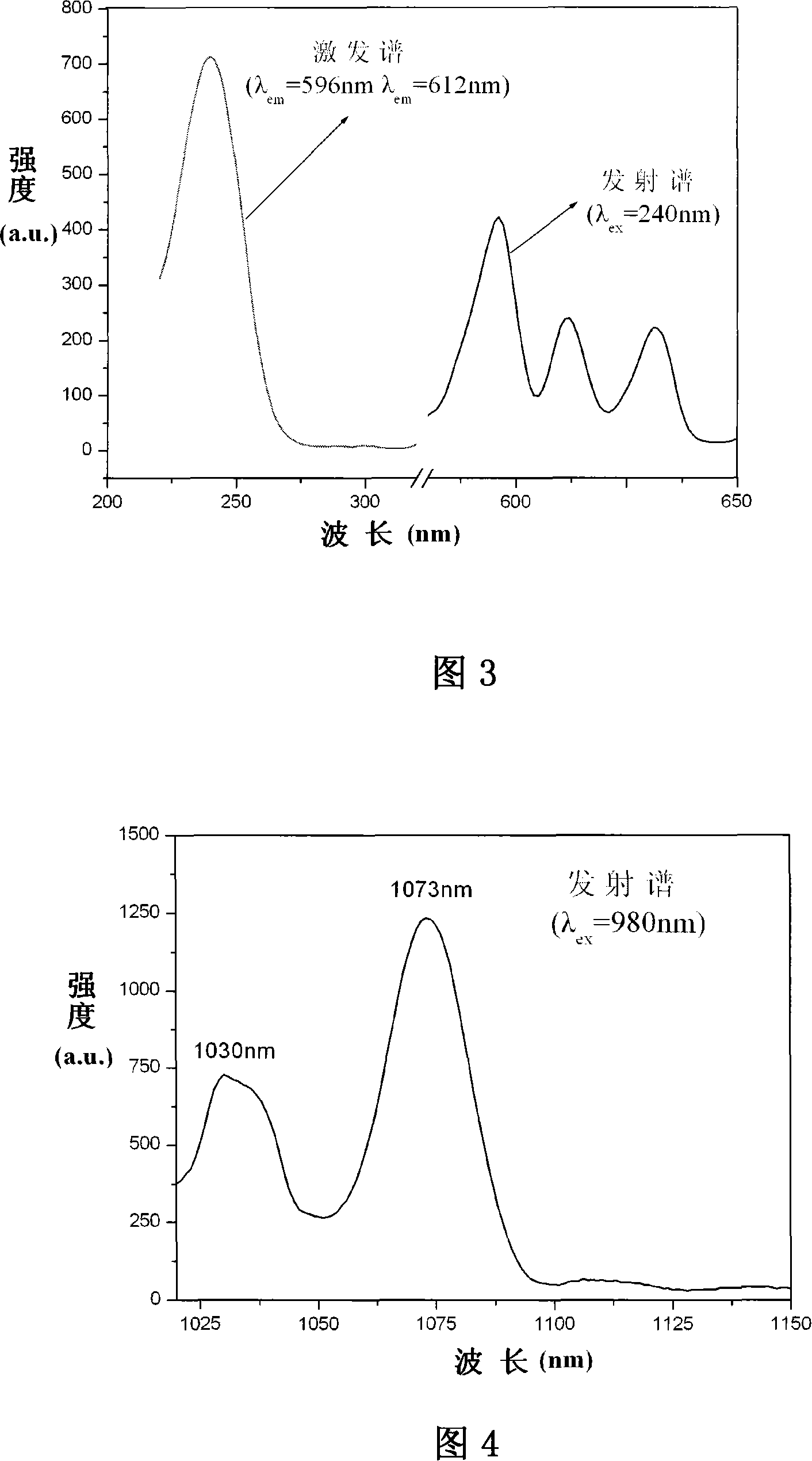

[0074] Preparation of Rare Earth Doped Ce by Pulling Method 3+ Ionic scandium aluminum magnesium oxide Ce x :Sc (1-x) AlMgO 4 Single crystal phosphor substrate as an example, Ce 3+ The ion is the ion with the largest radius in the lanthanide rare earth, and the specific preparation process is as follows:

[0075] (1) High-purity Al 2 o 3 (99.999%), MgO (99.99%), Sc 2 o 3 (99.999%) and CeO 2 (99.99%) After the raw material is calcined to remove impurities, the Al 2 o 3 , MgO, Sc 2 o 3 and CeO 2 , weighed a total of 300 grams according to the molar ratio of 1:2:(1-x):2x respectively, wherein x=1mol%, and fully mixed to form a mixed raw material;

[0076] (2) pressurize the above-mentioned mixed raw materials into a block with a diameter slightly smaller than the inner diameter of the crucible, and sinter in a muffle furnace at 1400° C. for 168 hours to carry out a solid-phase synthesis reaction;

[0077] (3) Put the sintered raw materials into the iridium crucible ...

Embodiment 2

[0083] Preparation of Ce-doped by pulling method 3+ Ionic scandium aluminum magnesium oxide ScAlMgO 4 Taking a single crystal fluorescent substrate as an example, the specific preparation process is as follows:

[0084] (1) High-purity Al 2 o 3 (99.999%), MgO (99.99%), Sc 2 o 3 (99.999%) and CeO 2 (99.99%) After the raw material is calcined to remove impurities, the Al 2 o 3 , MgO, Sc 2 o 3 and CeO 2 , respectively weighed a total of 300 grams according to the molar ratio of 1:2:(1-x):2x, wherein x=1mol%, and fully mixed to form a mixed raw material;

[0085] (2) pressurize the above-mentioned mixed raw materials into a block with a diameter slightly smaller than the inner diameter of the crucible, and sinter in a muffle furnace at 1450° C. for 168 hours to perform a solid-phase synthesis reaction;

[0086] (3) Put the sintered raw materials into the iridium crucible of the body-drawing furnace, and put the crucible into the hearth of the single crystal furnace to e...

Embodiment 3

[0091] Preparation of Ce-doped by pulling method 3+ Ionic scandium aluminum magnesium oxide ScAlMgO 4 Taking a single crystal fluorescent substrate as an example, the specific preparation process is as follows:

[0092] (1) High-purity Al 2 o 3 (99.999%), MgO (99.99%), Sc 2 o 3 (99.999%) and CeO 2 (99.99%) After the raw material is calcined to remove impurities, the Al 2 o 3 , MgO, Sc 2 o3 and CeO 2 , respectively 1:2:(1-x):2x molar ratio weighed a total of 300 grams, wherein x=1mol%, and fully mixed to form a mixed raw material;

[0093] (2) pressurize the above-mentioned mixed raw materials into a block with a diameter slightly smaller than the inner diameter of the crucible, and sinter in a muffle furnace at 1400° C. for 168 hours to perform a solid-phase synthesis reaction;

[0094] (3) Put the sintered raw materials into the iridium crucible of the body-drawing furnace, and put the crucible into the hearth of the single crystal furnace to ensure that the center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com