Method for preparing magnetic nano particles of anisotropy cobalt ferrite

A technology of magnetic nanoparticles and cobalt ferrite, which is applied in the direction of the magnetism of inorganic materials, can solve the problems of preparing single-phase nano-cobalt ferrite particles, and achieve the effect of complete crystallization and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

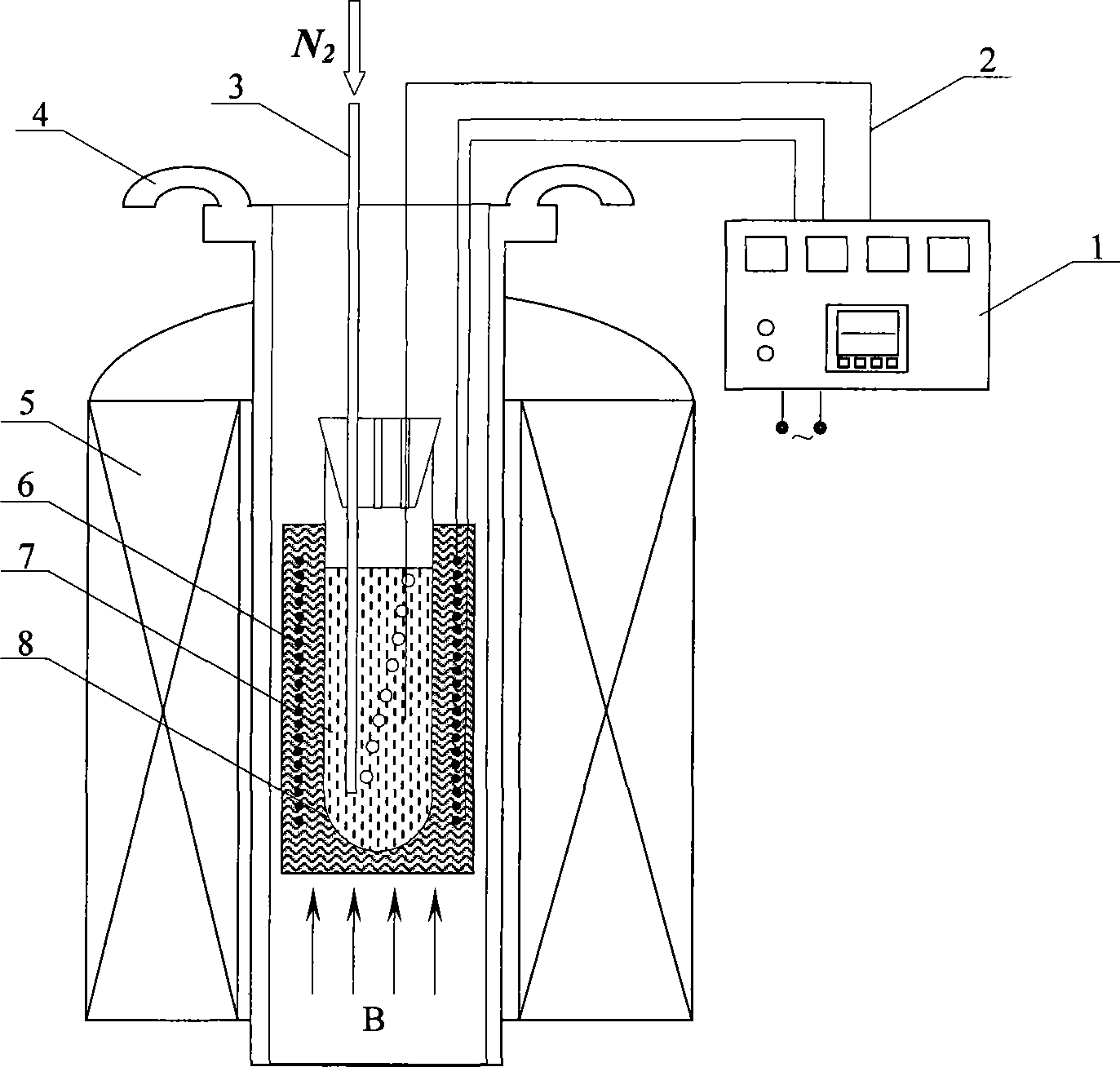

Image

Examples

Embodiment 1

[0019] Using analytically pure cobalt sulfate and ferric nitrate as raw materials, they are prepared into solutions of 0.5mol / L and 1mol / L respectively, measure 50ml of nickel sulfate solution and 50ml of ferric nitrate solution, put the above two solutions into a beaker, and then Add 100ml of sodium hydroxide solution with a precipitating agent concentration of 2mol / L, stir with a magnetic stirrer at room temperature for 5 minutes to make it evenly mixed, then heat to 60°C, stir to make it fully react, the cobalt and iron ions in the solution A co-precipitate of cobalt hydroxide and iron hydroxide will precipitate, forming a suspension. Then this suspension is poured in the quartz glass vessel of a strong magnetic field reactor, and this quartz glass vessel is placed in the heating device under strong magnetic field; The magnetic induction intensity of strong magnetic field is 8T (Tesla), and suspension is in Heating treatment in a strong magnetic field for 2 hours, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com