High-purity implanting planar array microelectrode and its production

A planar array and manufacturing method technology, applied in the direction of electrodes, artificial respiration, physical therapy, etc., can solve the problems of increasing the density of micro-electrode arrays, complex manufacturing process, and difficult realization, so as to improve the stimulation or recording effect, simple manufacturing process, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific characteristics of the high-density implantable planar array microelectrode manufacturing method provided by the present invention are further described below in conjunction with the accompanying drawings:

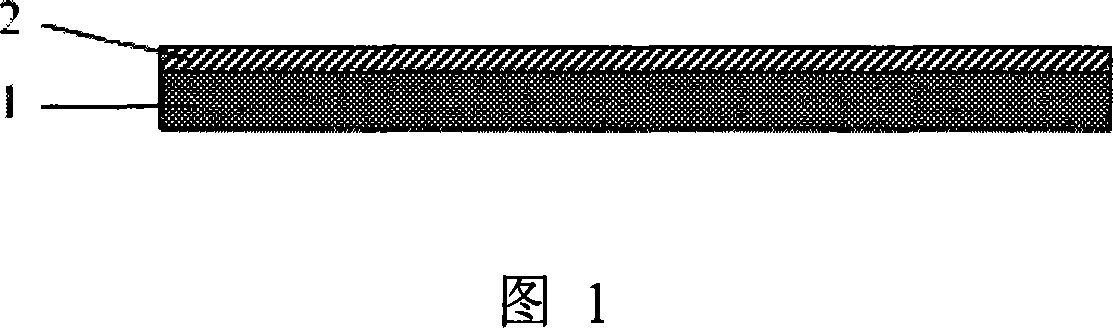

[0019] 1) Clean the silicon wafer 1 with a conventional semiconductor process cleaning method, and prepare an aluminum film 2 with a thickness of about 1 micron on the surface, as a sacrificial layer for electroplating conductive structures and release (Fig. 1);

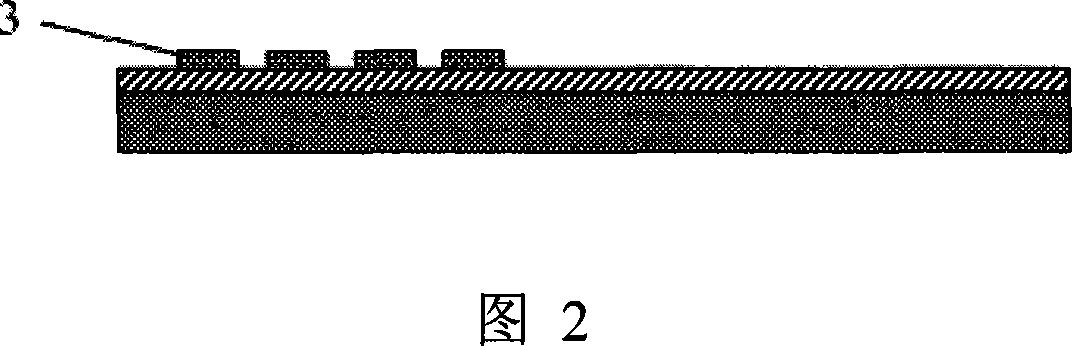

[0020] 2) Baking the silicon wafer at 120°C for 20 minutes, spin-coating 6809 photoresist (3000 rpm, 30 seconds) on the aluminum film layer of the silicon wafer, and pre-baking at 80°C for 20 minutes;

[0021] 3) Photolithography, sputtering Ti / Pt / Ti (2500 Ȧ), combined with Lift-off process, forming electrode stimulation site or recording site metal layer 3 (Fig. 2);

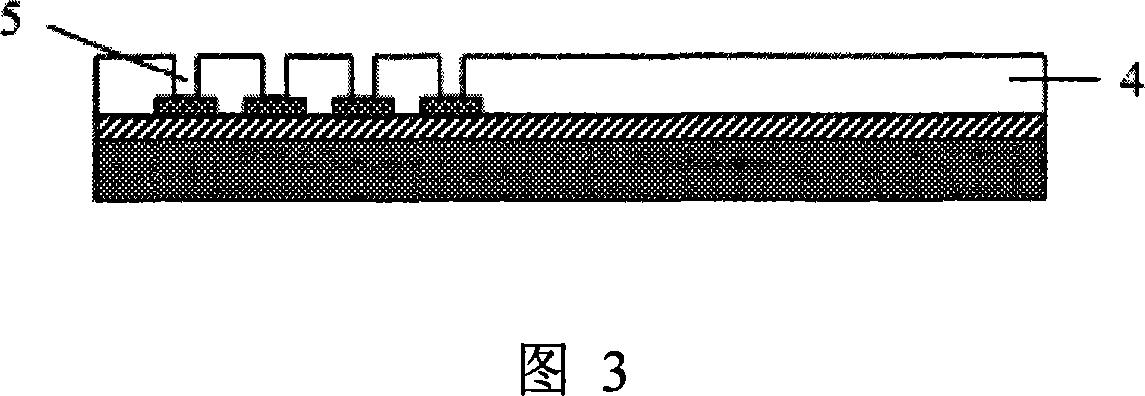

[0022] 4) Spin-coat photosensitive polyimide Durimide 7510 (3000 rpm, 30 seconds), make an isolation insulating layer 4, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com