Method for producing liquid sodium cyanide by tailed-oil thermal-pyrolysis

A technology of sodium cyanide and raffinate oil, applied in metal cyanide, simple alkali metal cyanide, chemical industry, etc., can solve the problems of large energy consumption, large amount of three wastes, etc., to improve conversion rate, reduce energy consumption, The effect of increasing the outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

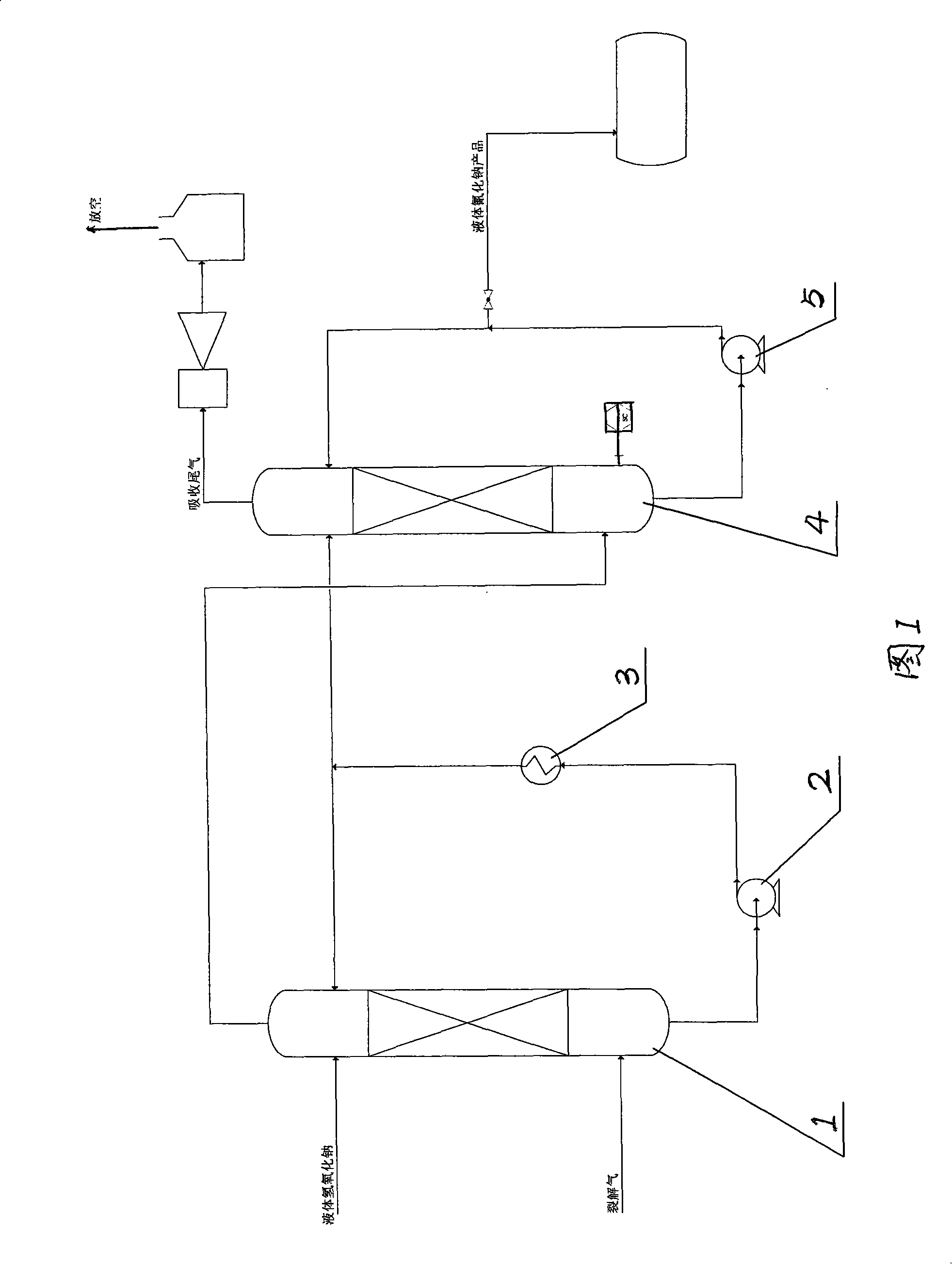

[0022] The production method of liquid sodium cyanide product, comprises the following process steps:

[0023] ① First, put the raffinate oil (generally with a density of 600-800kg / m 3 After the raffinate oil) and liquid ammonia are vaporized and mixed at a weight ratio of 1:2 to 1:5, they are put into a high temperature cracking furnace, and the sulfur content of petroleum coke is 0.1% to 0.5%; The particle size is 10-50 mesh) as a heat carrier, and thermal cracking is carried out at 1300-1500 ° C to generate a cracked gas containing hydrocyanic acid; in order to effectively improve the conversion rate of raffinate, the temperature of the gas outlet of the high-temperature cracking furnace is resistant to It can be controlled at 700-1000℃ by adjusting the amount of cooling water in the cracking furnace.

[0024] ② The pyrolysis gas is recovered by waste heat boiler, and after decoking and cooling, hydrocyanic acid is continuously absorbed by liquid sodium hydroxide to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com