Method for preparation of cross-linking hyaluronic acid sodium jelly glue implanted in eyes

A technology for cross-linking hyaluronic acid and sodium hyaluronate, which is applied in the field of medicine, achieves good resistance to enzymatic degradation, improves filtration and maintains filtration channels, and simplifies production steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

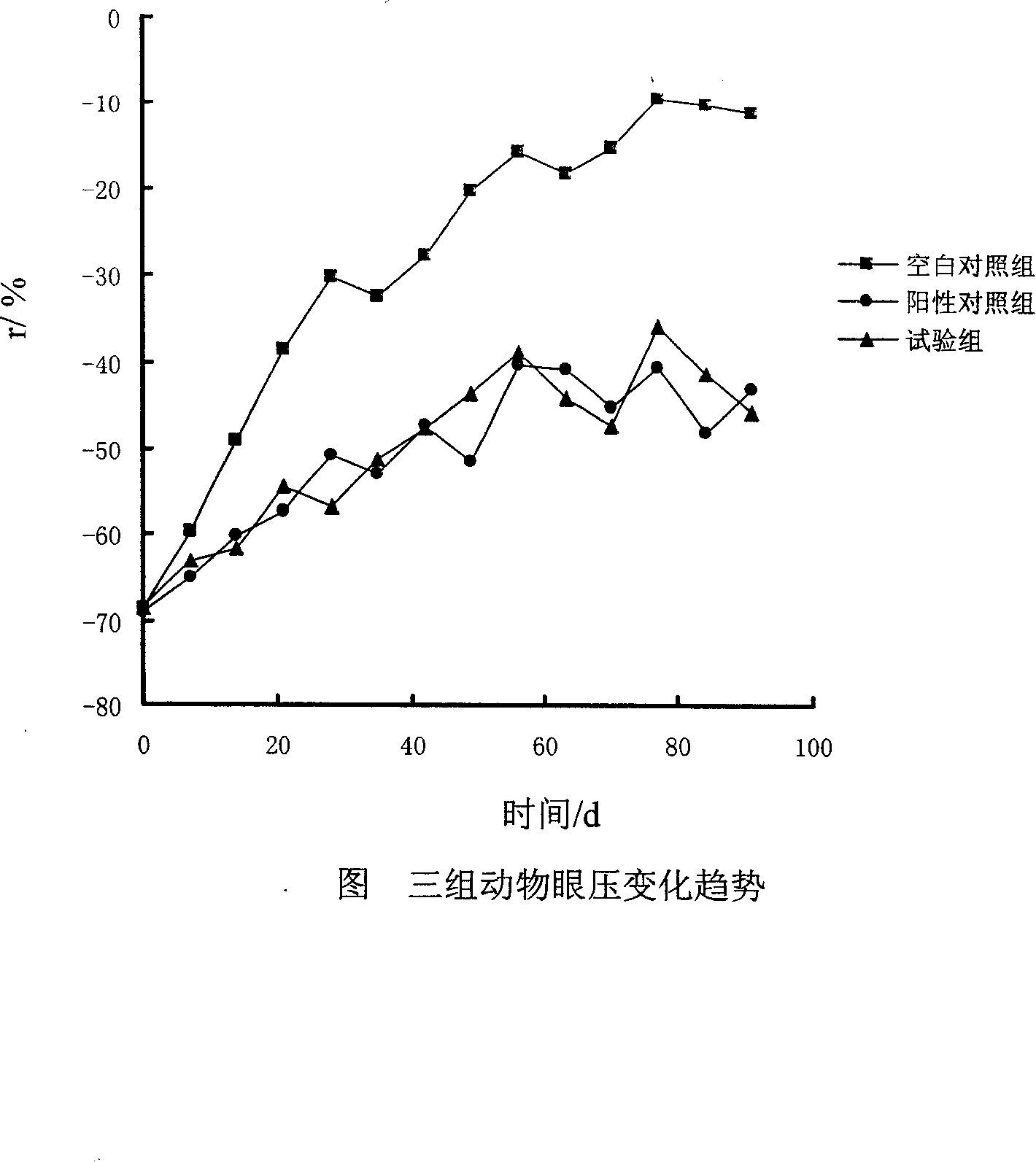

Image

Examples

Embodiment 1

[0021] Dissolve 0.125g SH (average molecular weight 1.415 million Daltons) in 5ml Tris-HCl (pH4.5) buffer solution, add ADH12.5mg, and mix well; another 30mg of EDCI is dissolved in 1ml Tris-HCl (pH4.5 ) buffer solution, then poured into the above mixed solution of SH and ADH, mixed quickly, and slowly poured into the gap between the two glass plates fixed in advance, after the reaction solution filled the gap, place the glass plate horizontally , and react for 2 to 24 hours until the reaction solution is completely gelled.

[0022] The two glass plates are rectangular small glass pieces of the same size, with a thickness of about 0.3mm and an area of about 3cm×7cm. The gap between the glass plates is fixed by placing a small gasket of a certain thickness between the two small glass pieces. Realization, the small spacer is a glass sheet or hard non-toxic plastic with a thickness of 0.45mm and a size of about 0.5cm×3cm. It is inserted between two small rectangular glasses alo...

Embodiment 2

[0025] Dissolve 0.125g SH (average molecular weight: 370,000 Daltons) in 5ml Tris-HCl (pH4.0) buffer solution, add ADH21.7mg, mix well; dissolve EDCI 30mg in 1ml Tris-HCl (pH4.0) buffer solution, then poured into the above mixed solution of SH and ADH, mixed quickly, and slowly poured between two glass plates with a gap width of 0.47mm. After the reaction solution filled the gap, place the glass plate horizontally, and react 2 to 24 hours, until the reaction solution is completely gelled. The preparation of the glass plates is basically the same as that in Example 1, except that the thickness of the small spacers sandwiched between the glass plates is 0.47 mm. The purification, cutting, packaging and sterilization of the gel are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com