Glycosyl quaternary ammonium salt cation surfactant, preparation method and application

A technology of surfactants and sugar-based quaternary ammonium salts, which is applied in amino sugars, chemical instruments and methods, and dissolution, and can solve problems such as difficult purification, unreported reports, and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of N-Hexyl Glucosamine

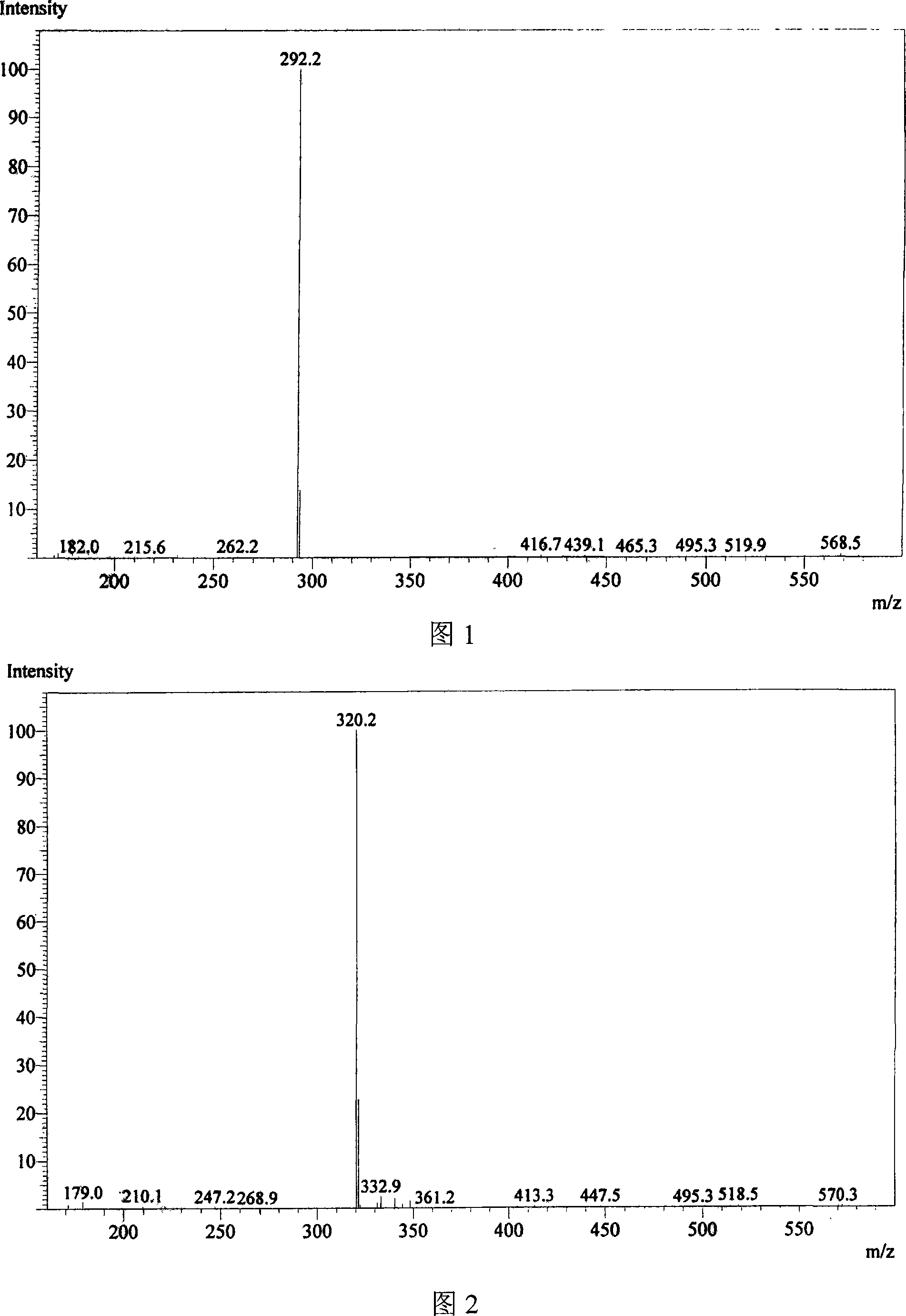

[0037] In a 250mL three-neck flask equipped with a thermometer and a spherical condenser, add 10.0g (56mmol) of anhydrous glucose, 11.1mL (84mmol) of hexylamine, and 150mL of methanol. After reacting under magnetic stirring at 30-35°C for 6-8 hours, the temperature was raised to 50-55°C, and the reaction was continued for 2-3 hours. TLC showed that the reaction was complete. Heating was stopped, and the system was left to cool, and a white solid slowly precipitated out of the system. It was suction-filtered and washed twice with 100 mL of petroleum ether to remove residual hexylamine to obtain 13.0 g of white needle-like crystals. Yield: 87.8%, melting point: 94.4-94.7°C, and its structure was characterized by electrospray mass spectrometry.

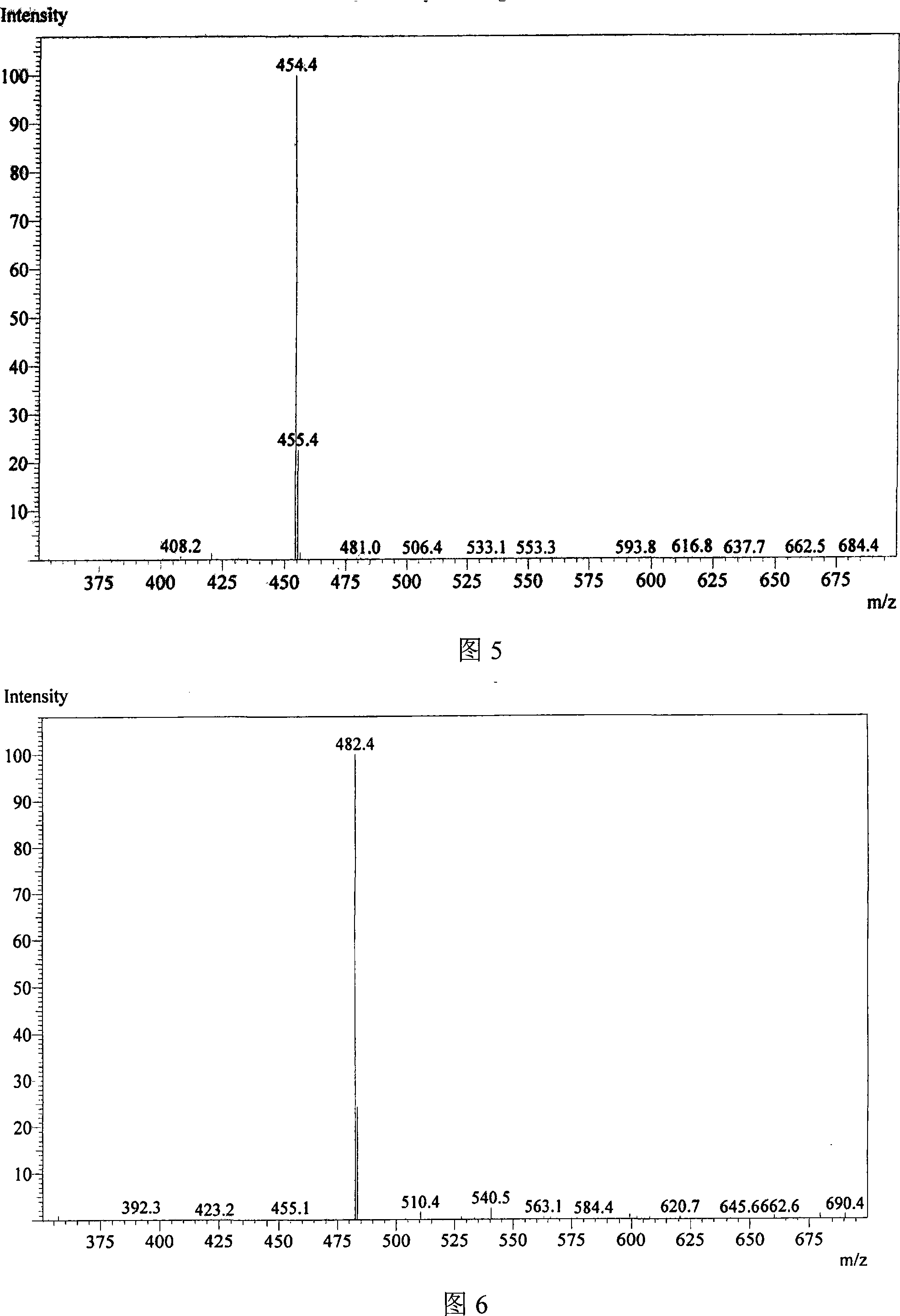

[0038] Synthesis of N-Hexyl Glucosamine Quaternary Ammonium Salt

[0039] In a 100mL flask, 20g (76.0mmol) of N-hexylglucosamine, CH 3 18.3mL (304.0mmol) of I was dissolved in 50mL of DMF, an...

Embodiment 2

[0041] Synthesis of N-octylglucosamine

[0042] In a 250mL three-necked flask equipped with a thermometer and a spherical condenser, add 10.0g (56mmol) of anhydrous glucose, 13.9mL (84mmol) of octylamine, and 150mL of methanol. React under magnetic stirring at 30-35°C for 6-8 hours, then raise the temperature to 50-55°C, continue to react for 2-3 hours, and TLC shows that the reaction is complete. Heating was stopped, and the system was left to cool, and a white solid slowly precipitated out of the system. Suction filtration and washing with 100 mL of petroleum ether twice to remove residual octylamine gave 15.0 g of white flaky crystals. Yield: 92%, melting point: 101.8-102.5°C. And its structure was characterized by electrospray mass spectrometry.

[0043] Synthesis of N-octylglucosamine quaternary ammonium salt

[0044] In a 100mL flask, 20g (68.7mmol) of N-octylglucosamine, CH 3 I 17.2mL (247.7mmol) was dissolved in DMF 50mL, and sodium carbonate 7.29g (137.3mmol) was...

Embodiment 3

[0046] Synthesis of N-dodecylglucosamine

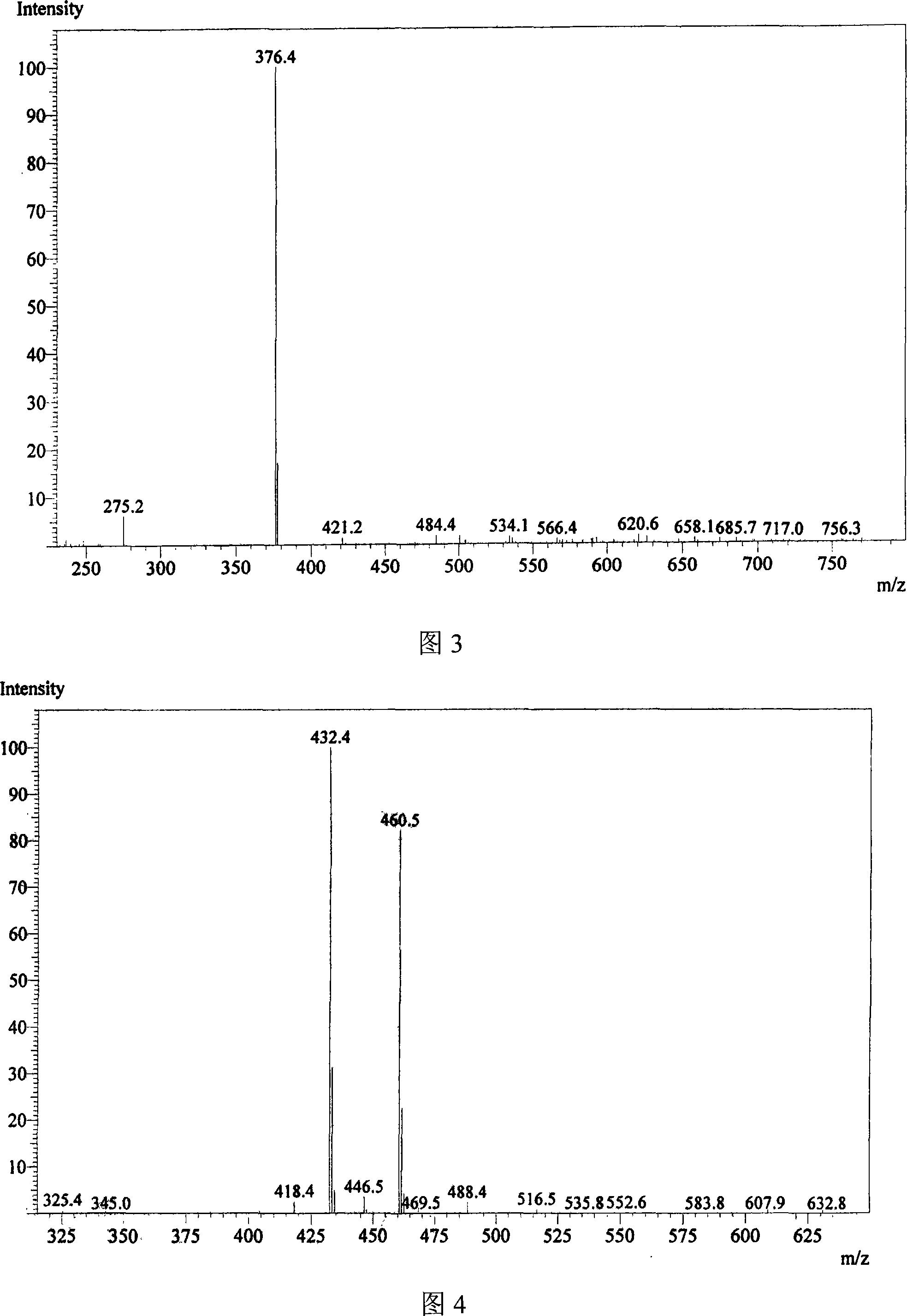

[0047]In a 250 mL three-necked flask equipped with a thermometer and a spherical condenser, 5.0 g (28 mmol) of anhydrous glucose, 7.7 g (42 mmol) of dodecylamine, and 120 mL of methanol were added. React under magnetic stirring at 25-30°C for 6-8 hours, and the system solidifies into a white precipitate. When the temperature was raised to 50-55°C, the system became clear again. The reaction was continued for 2-3 hours, and TLC showed that the reaction was complete. Heating was stopped, and the system was left to cool, and a white solid slowly precipitated out of the system. Suction filter and wash twice with 100 mL of V (acetone): V (n-hexane) = 7: 3 mixed solvent to remove residual dodecylamine to obtain 8.95 g of crude product. Recrystallized from ethanol to obtain 7.6 g of white needle-like crystals. Yield: 79.1%, melting point: 105-106°C, literature value: 107.5-109°C. And its structure was characterized by electrospray mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com