Liquid crystal alignment agent and liquid crystal display unit for ink-jet coating

A liquid crystal alignment agent, inkjet technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of poor coating, clogging of inkjet nozzles, uneven coating, etc., and achieve excellent uniformity of film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

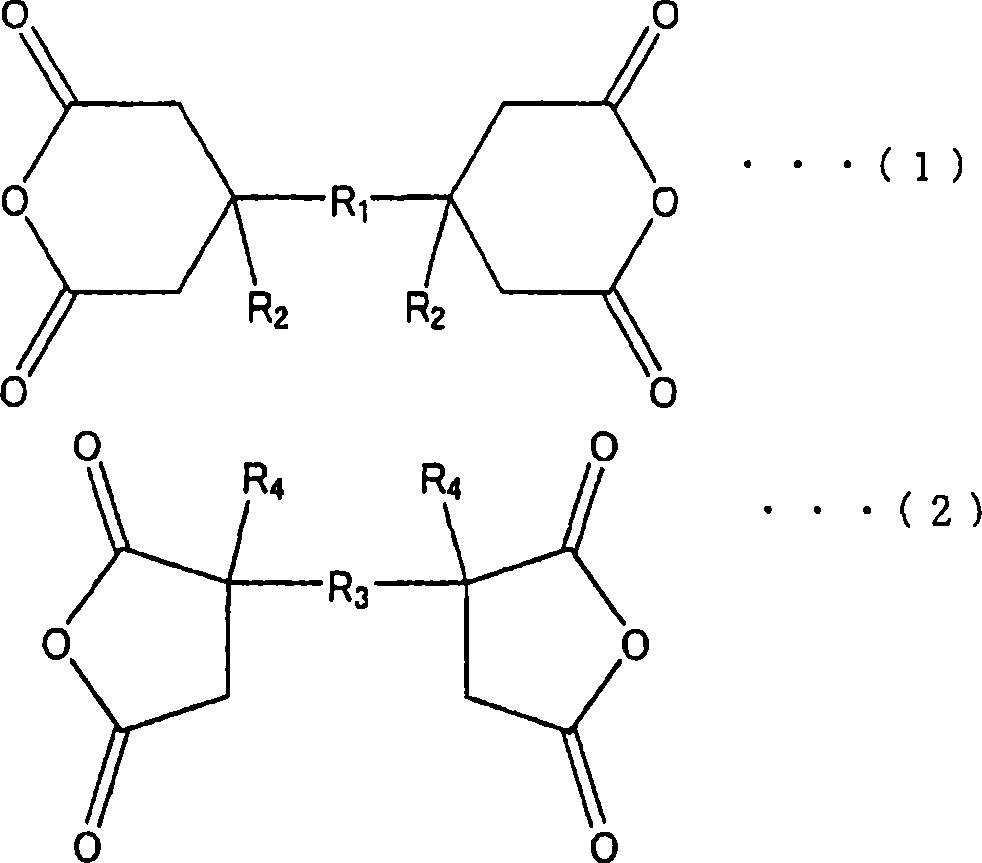

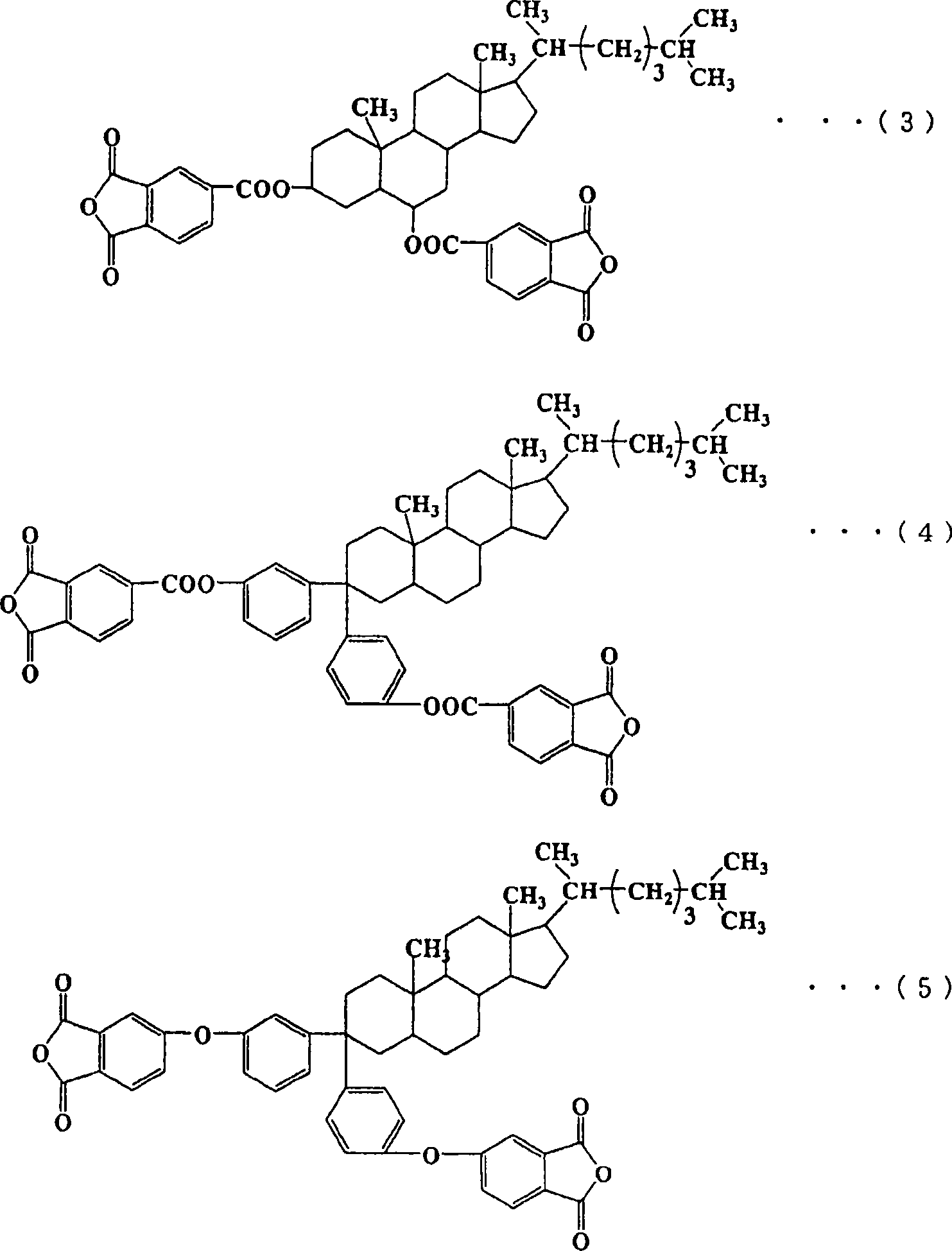

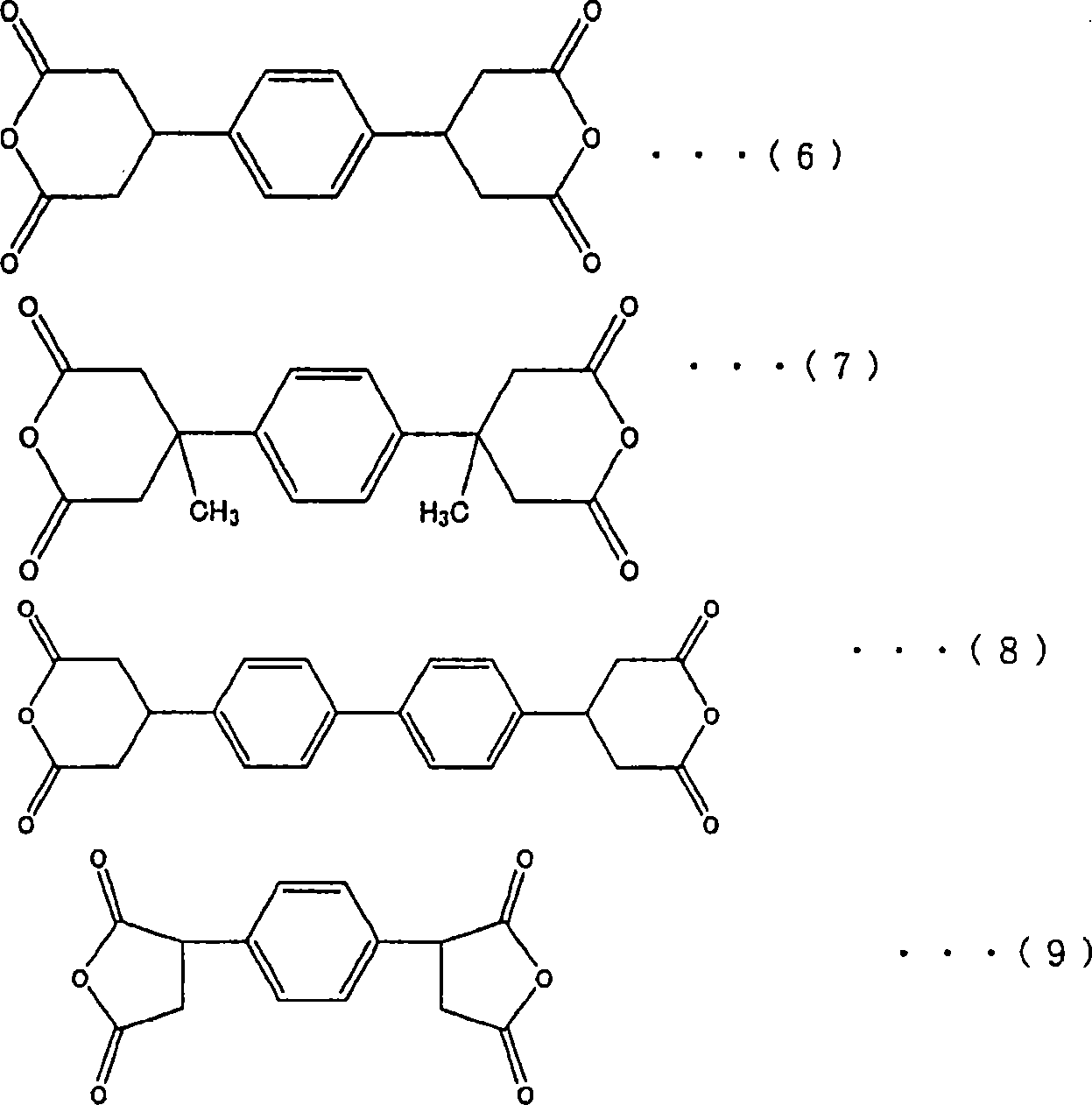

Method used

Image

Examples

Embodiment

[0093] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In Examples and Comparative Examples, polymer molecular weight measurement, imidization rate measurement, liquid crystal aligning agent inkjet coating property, viscosity, particle number measurement, and measurement of voltage holding rate of manufactured cell were evaluated by the following methods .

[0094] [Weight average molecular weight and molecular weight distribution]

[0095] Gel permeation chromatography (GPC, manufactured by Tosoh Corporation, trade name: HLC-8020 / 3 columns: manufactured by Tosoh Corporation, trade names: TSK guardcolum α, TSK gel α-M, TSK gel α -2500), using dimethylformamide (DMF; 9.4 g of lithium bromide monohydrate and 1.7 g of phosphoric acid were added to 3 L of DMF) as a solvent, and the polystyrene-equivalent weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn). Wherein, the abo...

Synthetic example 1

[0106] Synthesis example 1 (synthesis of polyamic acid P-1)

[0107] 38 g (0.17 mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride, 12 g (0.057 mol) of pyromellitic dianhydride, p-phenylenediamine as diamine compound 19 g (0.17 mol) and 30 g (0.058 mol) of diamine represented by the above formula (14) were dissolved in 400 g of N-methyl-2-pyrrolidone, and reacted at 60° C. for 4 hours. In preparation of a liquid crystal aligning agent, this polymerization solution was used as it is. Moreover, the molecular weight of the polyamic acid in this polymerization liquid (this is referred to as "polymer P-1") measured by gel permeation chromatography was Mw=153,000, Mw / Mn=6.36.

Synthetic example 2

[0108] Synthesis example 2 (synthesis of imidized polymer P-2)

[0109] With 2,3,5-tricarboxycyclopentyl acetic acid dianhydride 21g (0.093 mole) as tetracarboxylic acid dianhydride, p-phenylenediamine 9.2g (0.085 mole) as diamine compound, above-mentioned formula (14) 4.9 g (0.0095 mol) of the indicated diamine was dissolved in 140 g of N-methyl-2-pyrrolidone, and reacted at 60° C. for 5 hours. 360 g of N-methyl-2-pyrrolidone was added to the obtained polymerization liquid, and after stirring well, 7.4 g of pyridine and 9.5 g of acetic anhydride were added, and dehydration and ring closure were performed at 110° C. for 4 hours. After the imidization reaction, the solvent in the system is replaced with a new N-methyl-2-pyrrolidone (in this operation, the pyridine and acetic anhydride used in the imidization reaction are removed outside the system), An imidized polymer solution having a solid content concentration of 17% by weight was obtained. In addition, the molecular weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com