Chip interchangeable microflow control chip proteolysis reactor

A technology of microfluidic chip and proteolysis, which is applied in the field of replaceable microfluidic chip proteolysis reactor and its preparation, which can solve the problems of scrapping chips, limiting the widespread use of microfluidic chip enzyme reactors, and environmental impact. , to achieve the effect of improving use efficiency, good application prospects, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further describe the present invention below by embodiment and accompanying drawing:

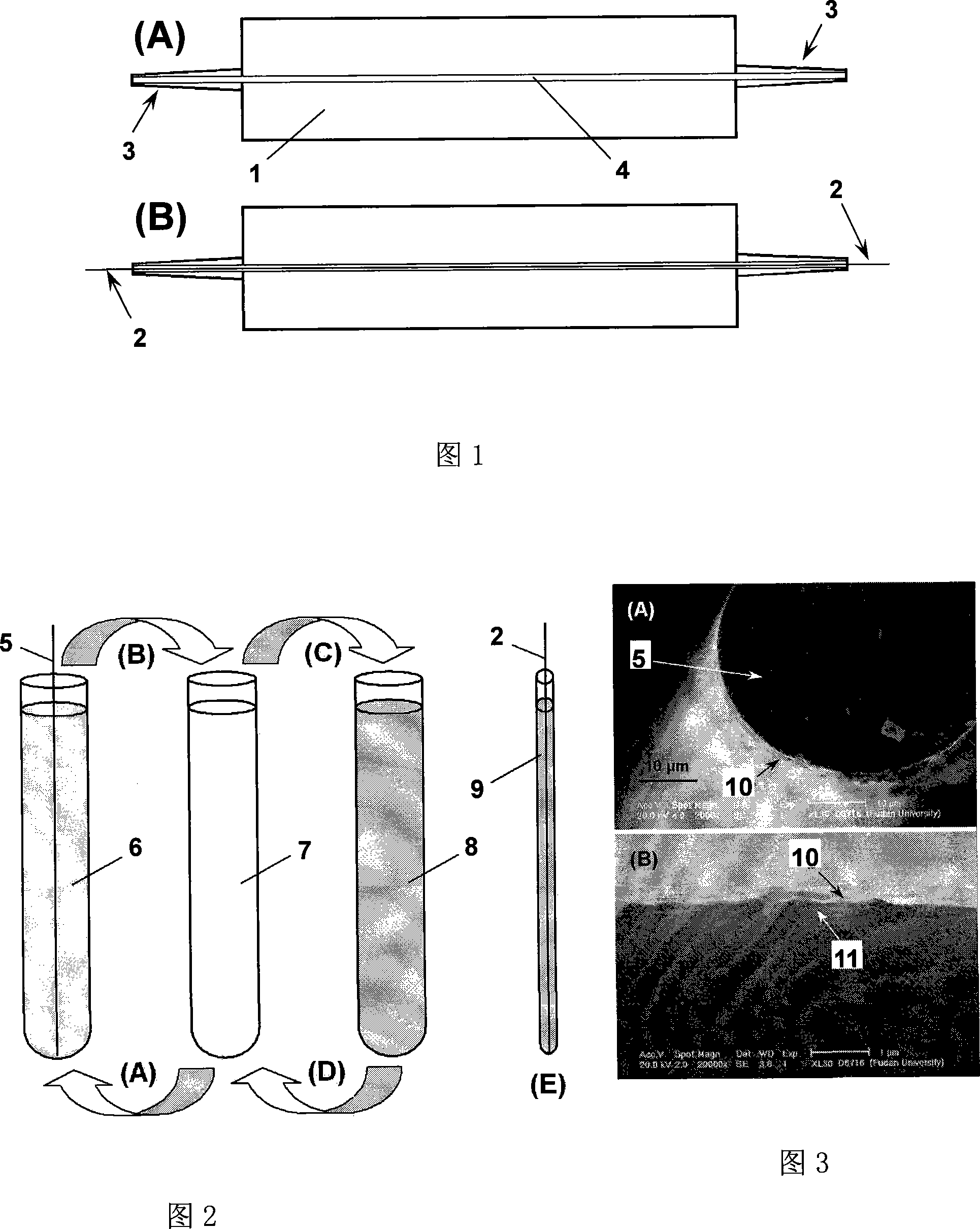

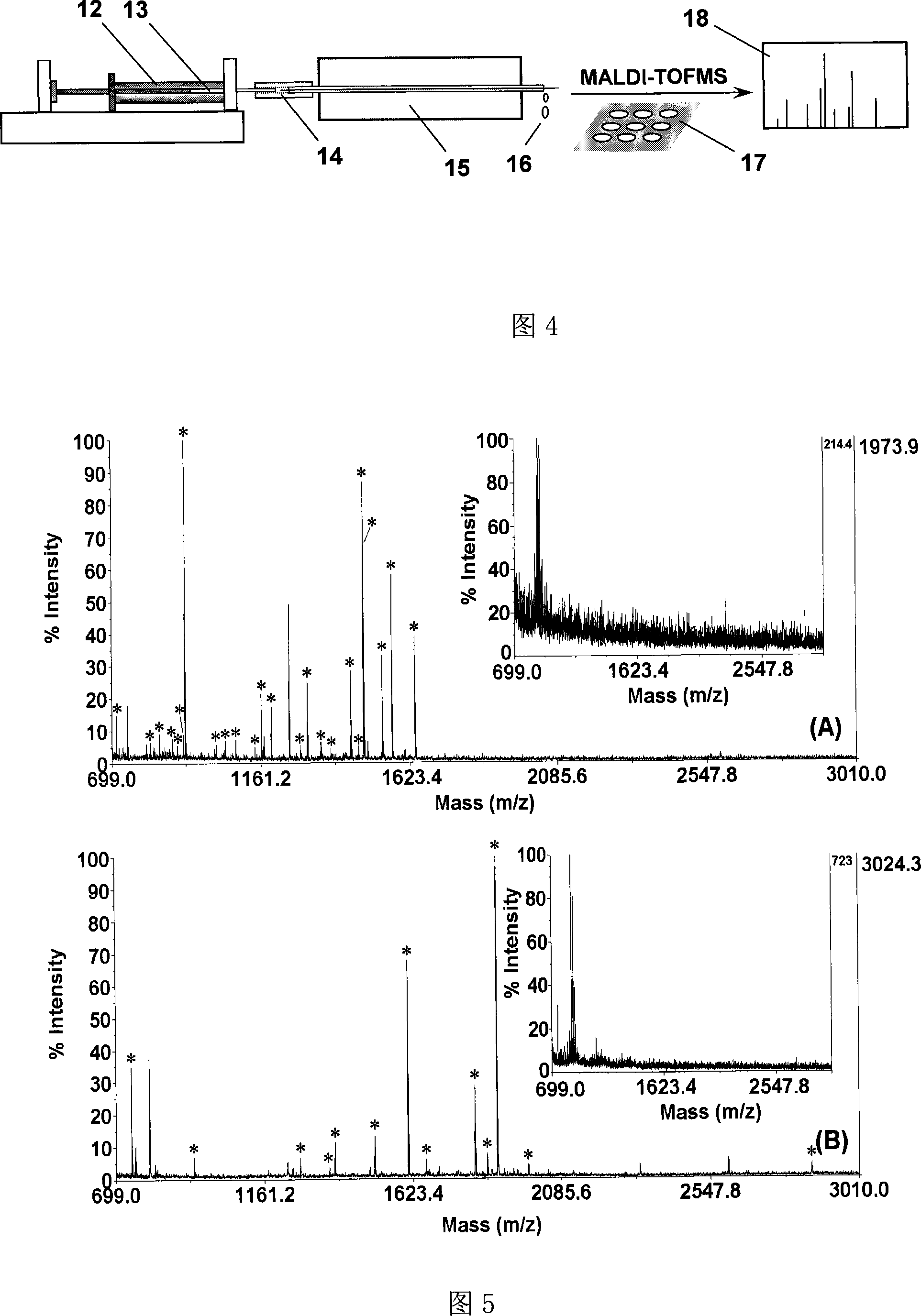

[0029]1. Preparation of replaceable core microfluidic chip enzyme reactor by layer-by-layer self-assembly method and its application

[0030] Computer-aided design software is used to design the chip structure, which is composed of a single microfluidic channel. A high-resolution (such as 3600dpi) laser phototypesetting system is used to print a mask on a transparent film. The microchannel part is black lines with a width of 60 microns, and other parts is transparent. A layer of positive photoresist (Shipley S1813 Photoresist, Shipley, Marlborough, MA, USA), spin-coating conditions were 3000 rpm for 60 seconds. Then bake at 110°C for 60 seconds to improve the adhesion of the photoresist and remove the residual solvent (baking before exposure), and then cover the mask (including the designed microfluidic structure), using Karl Suss MA6 / BA6 photolithography After 40 seconds of contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com