Method for producing pure triethanolamine containing micro-water

A technology of triethanolamine and production process, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of discontinuous production process, unstable product quality, low production efficiency, etc., and achieve stable product quality, The effect of low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

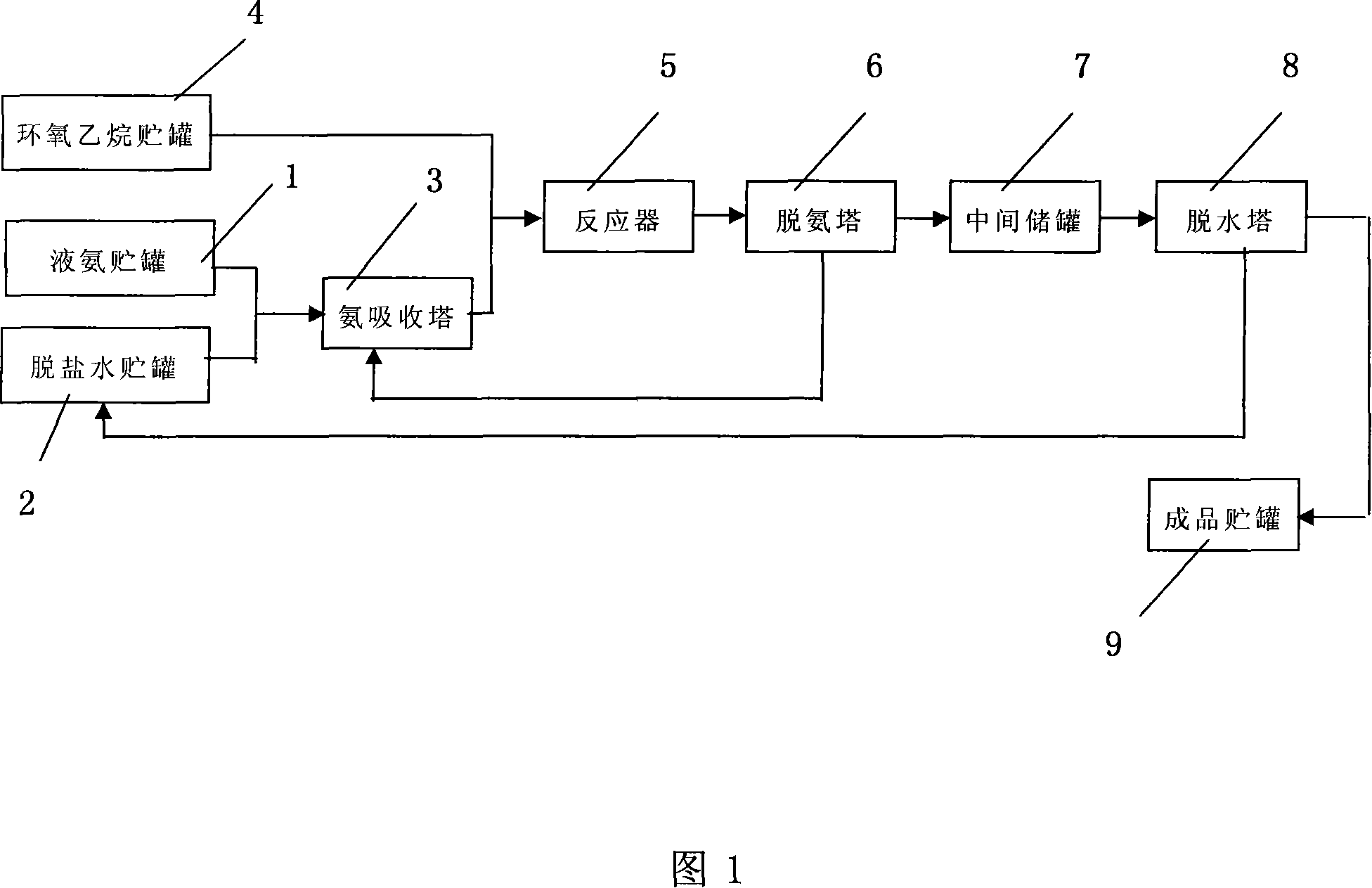

Method used

Image

Examples

Embodiment 1

[0020] (1) Ammonia absorption process:

[0021] Liquid ammonia is transported to the bottom of the ammonia absorption tower 3 at a pressure of 1500kPa (gauge pressure) and an ammonia flow rate of 120kg / h, and is transported from the desalted water storage tank 2 to the top of the ammonia absorption tower 3 by a pump with a water volume of 1200kg / h Water, operating pressure at the top of the tower is 100kPa (gauge pressure), temperature is 35 ℃, after 2.5h, be dissolved into the ammoniacal solution of 10% in concentration, then, stop replenishing liquid ammonia and water, the liquid level at the bottom of the tower is 40% ;

[0022] (2) ethanolamine generation reaction process:

[0023] 10% aqueous ammonia solution is delivered to the reactor 5 at one time with a flow rate of 1800kg / h, and ethylene oxide is delivered to 5 tubular reactors 5 in series with a flow rate of 185kg / h respectively. The total amount of oxyethane fed was 925 kg. Adopt intercooler to control the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com