Castorite/cordierite multi-phase low-buckling ceramic and preparation method thereof

A technology of petalite and cordierite, which is applied in the field of petalite/cordierite composite ceramics and its preparation, can solve the problems of high thermal expansion coefficient, no main crystal phase, high spodumene dosage, etc., and achieve white High strength, good mechanical strength, excellent thermal stability

Inactive Publication Date: 2008-01-30

JINGDEZHEN CERAMIC UNIV

View PDF2 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In addition, the main crystal phases of the most commonly used lithium-based low-expansion ceramic products at home and abroad are spodumene and petalite. There is no report that the main crystal phase is composite petalite / cordierite

As described in Chinese patent document 200510023142.0 "a high thermal shock resistance ceramic and its manufacturing method", the blank is made of calcined spodumene powder, high-quality kaolin, quartz and sintering accelerators such as titanium dioxide and zirconium dioxide to synthesize β- The main crystal phase of spodumene, although it has a low thermal expansion coefficient (-0.2-1.5×10 -6 ℃), but the amount of spodumene is as high as 35-55%, and chemical raw materials such as titanium dioxide and zirconium dioxide are added, and the cost is relatively high; and as disclosed in patent document 200510035605.5 "medium temperature heat-resistant ceramics and its manufacturing method", the ingredients Petalite feldspar, kaolin and lithium carbonate are used to synthesize petalite feldspar main crystal phase, wherein the amount of petalite feldspar is 42-70%, the amount of lithium carbonate is 0-8%, and its cost is obviously higher than this Invention patent, but its thermal expansion coefficient is high, reaching 2.0-3.0×10 -6 / °C

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

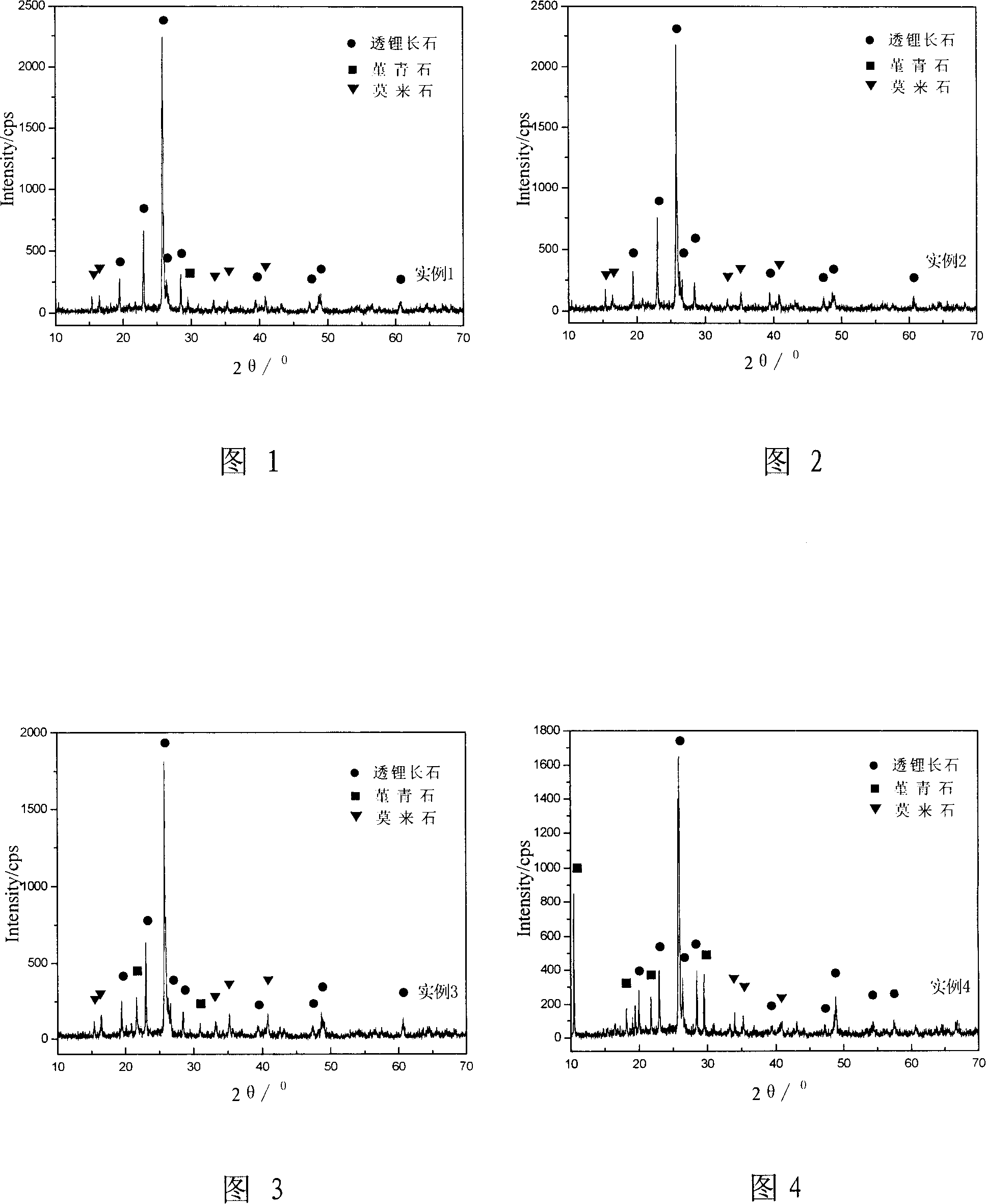

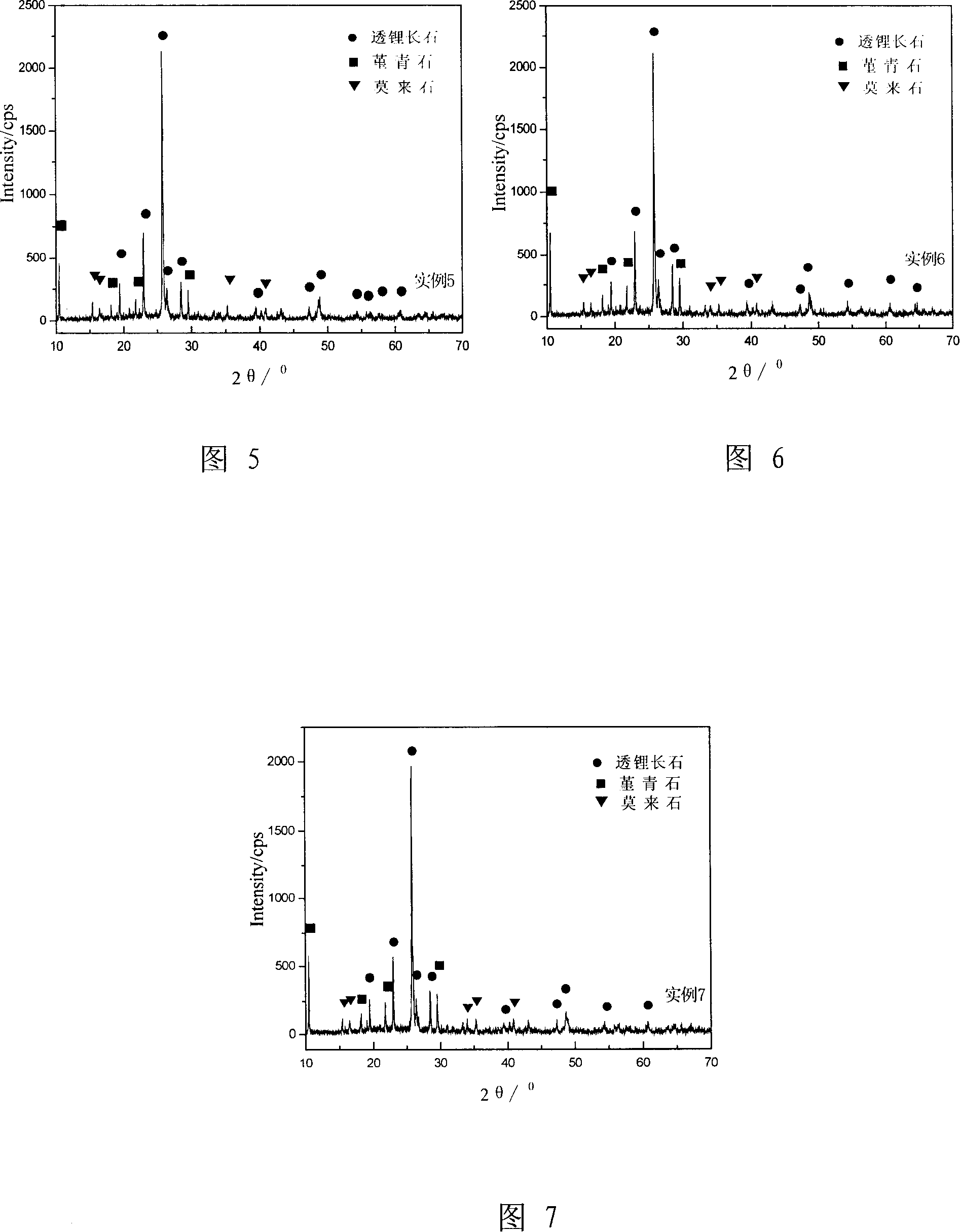

Embodiment 1~7

[0012] Raw materials were prepared according to the composition in Table 1, and lithium petalite / cordierite composite ceramics with low expansion properties were obtained through crushing, mixing ball milling, sieving, molding, and sintering.

[0013] Table 1 Composition and properties of petalite / cordierite composite ceramics

[0014] Example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a petalite / cordierite multiphase low expansion ceramic and preparation method thereof. The invention is characterized in that: the invented low expansion ceramic with a main crystal phase of compound petalite and cordierite multiphase crystal structure is made from the following materials that are: petalite, kaolin and talc, and adopts common sintering method of ceramic. The heat expansion coefficient Alpha is 1.0-2.0 multiplied by 10-6 DEG C. The low expansion ceramic with good thermal stability can be made without using expensive lithium containing material such as spodumene and lithium carbonate. The invention can be broadly used in making kiln furniture, high temperature clamp, high temperature radiation baffle, homely heat-resistant tableware, and thermocouple protective tube, etc.

Description

technical field [0001] The invention belongs to the field of inorganic non-metallic materials (ceramics), and relates to petalite / cordierite composite ceramics with low expansion characteristics and a preparation method thereof. Background technique [0002] Low-expansion ceramics refer to thermal expansion coefficients less than 2.0×10 -6 / °C ceramics. Low expansion materials have been widely used in ceramics, metallurgy, enamel, special glass, chemical industry, etc., and lithium low expansion ceramics are favored due to their excellent high temperature resistance, thermal shock resistance and high temperature chemical stability. It is widely used in ceramic blanks, glazes, kiln furniture, induction heating parts (such as microwave oven gaskets), astronomical telescope mirror blanks, and heat-resistant tableware for household use. [0003] At present, the commonly used lithium-based low-expansion ceramics mainly use industrial lithium carbonate (Li 2 CO 3 ) and natural...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/19C04B35/195C04B35/622

Inventor 李月明张玉平黄丹

Owner JINGDEZHEN CERAMIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com