Hydrophobic rare earth long-afterglow luminescent material, luminescent plastic and method for making same

A long-lasting luminescent and hydrophobic technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of ensuring the compatibility of powder luminescent materials with various matrix resins and affecting the luminescent properties and mechanics of polymer materials. Performance, rare earth luminescent materials are difficult to uniformly disperse and other issues, to achieve the effect of strong designability, expanding the scope of use, and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of the hydrophobic rare earth long-lasting luminescent material of the present invention

[0045] Raw materials: 50g of rare earth-doped strontium aluminate coated with silicon-aluminum binary film (provided by Sichuan University);

[0046] Coupling agent (γ-methacryloxypropyltrimethoxysilane) 4g;

[0047] Ethanol 200ml.

[0048] Add the above raw materials into the reactor, stir at 70° C. for 5 hours; dry and remove the solvent to obtain about 50 g of yellow-green powdery hydrophobic rare earth long-lasting luminescent material.

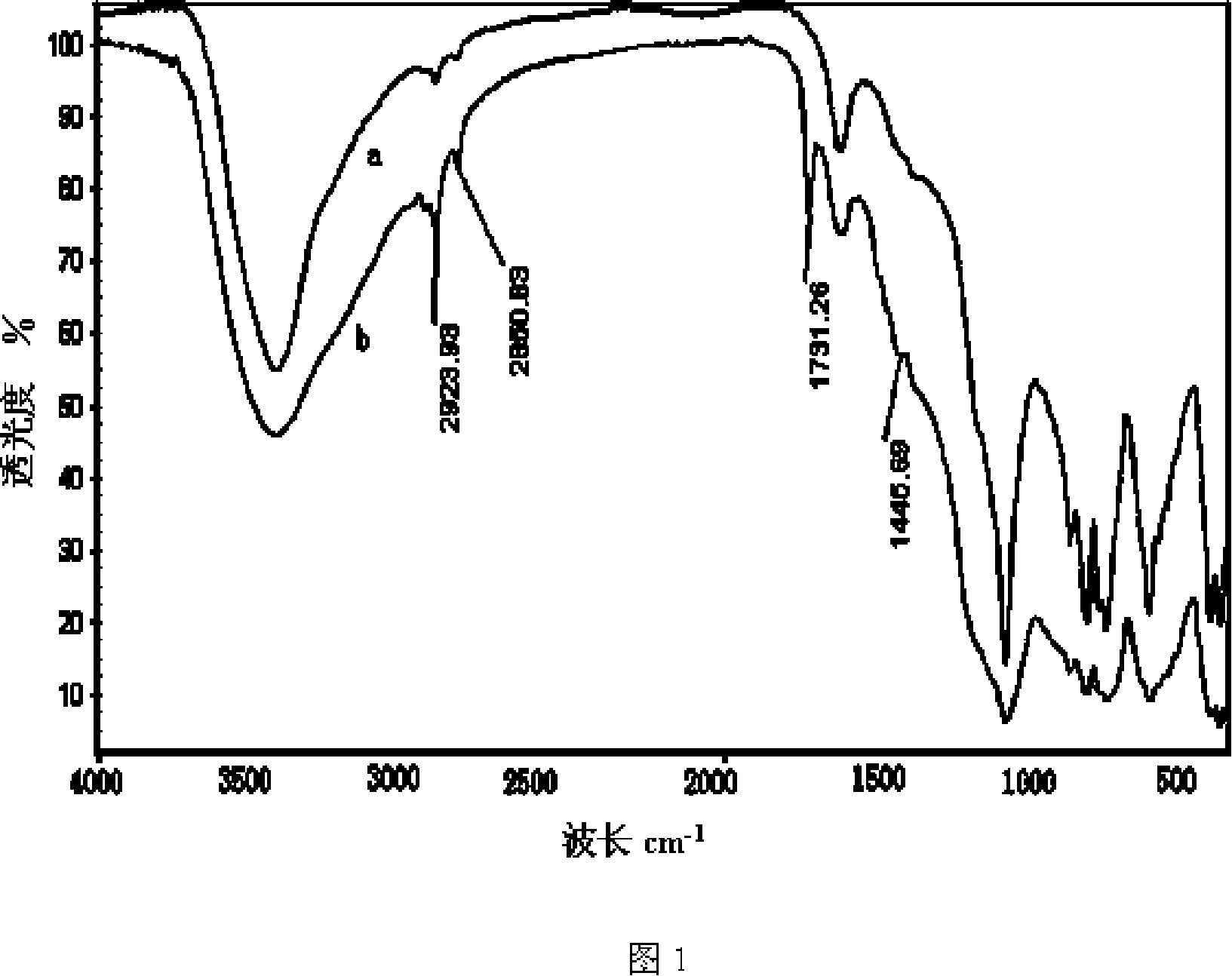

[0049] Coupling rare earth-doped strontium aluminate with MAPS coupling modified silicon-aluminum binary film can chemically adsorb silane coupling agent molecules on the surface of silicon-aluminum binary film-coated rare earth-doped strontium aluminate to make silicon-aluminum binary The film-coated rare earth-doped strontium aluminate band has unsaturated double bonds, which become a bridge between inorganic powder ...

Embodiment 2

[0051] Example 2 Preparation of the hydrophobic rare earth long-lasting luminescent material of the present invention

[0052] Raw material: 4g of the sample (Sample 3) of Patent Application No. 200610172187.9;

[0053] Coupling agent (γ-methacryloxypropyltrimethoxysilane) 0.32g;

[0054] Ethanol 16ml.

[0055] The above raw materials were put into a reactor equipped with a stirrer, a thermometer and a reflux condenser, and stirred at 75° C. for 5 hours; the solvent was dried and removed to obtain about 4 g of a yellow-green powdery hydrophobic rare earth long-lasting luminescent material.

Embodiment 3

[0056] Example 3 Preparation of hydrophobic rare earth long-lasting luminescent material of the present invention

[0057] Using the same method as in Example 1, use 4%, 6%, 8% and 10% of the MAPS coupling agent to modify the silicon-aluminum binary film to coat the rare earth-doped strontium aluminate, and extract it with absolute ethanol after drying. Extracted for 48 hours, and then dried at 120°C to prepare coupling-modified samples with different coupling agent dosages.

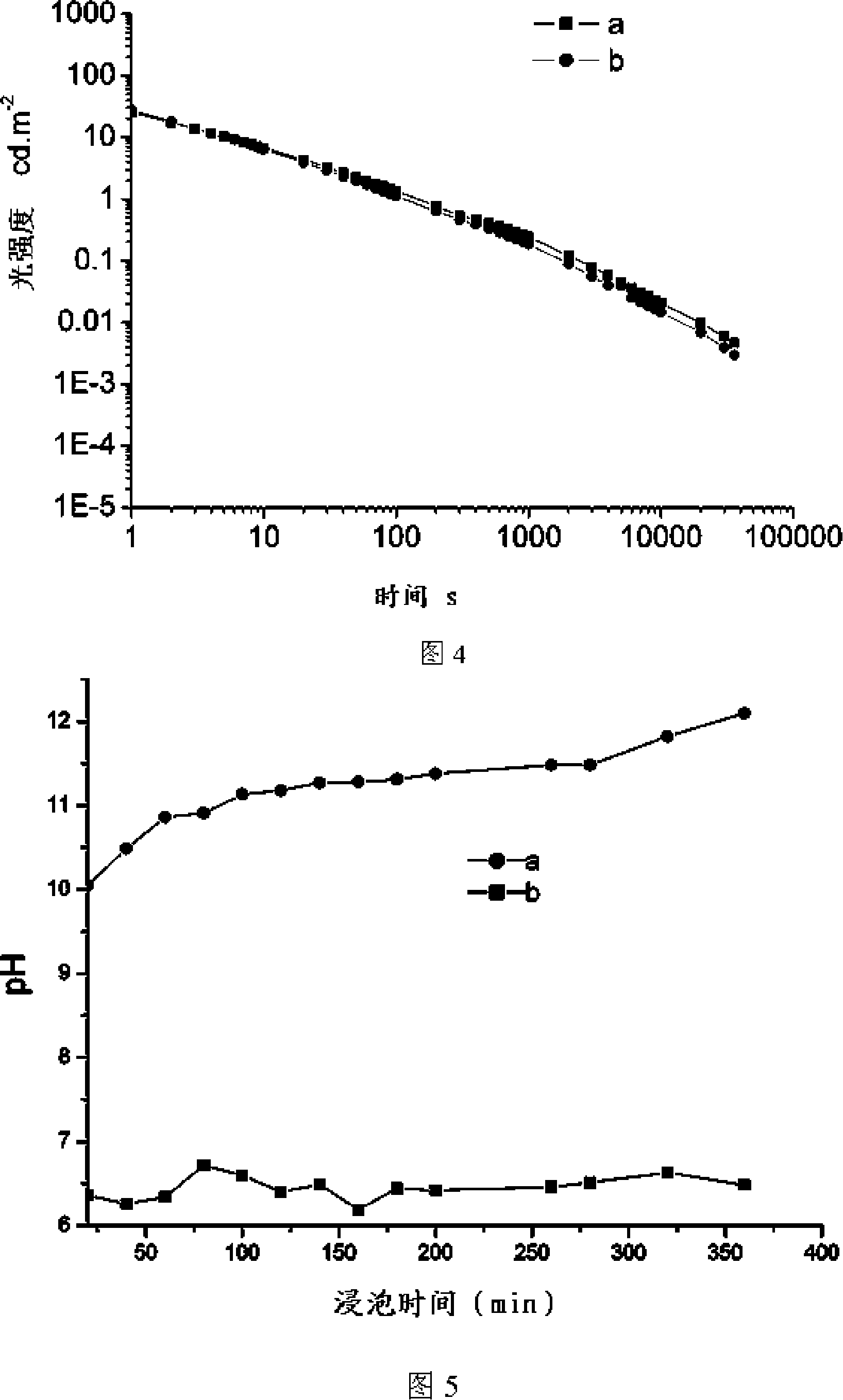

[0058] Hydrophobic test: all the coupling modified samples and the silicon-aluminum binary membrane coated rare earth doped strontium aluminate without coupling modification were dispersed in deionized water, and the hydrophobic characteristics of the samples were observed and evaluated. The results showed that there was no The rare-earth-doped strontium aluminate coated with silicon-aluminum binary membrane modified by coupling has strong hydrophilicity, and all sink to the bottom of the container soon;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap