Method for preparing secoisolariciresinol diglucoside

A technology of secoisolarix and glucoside, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

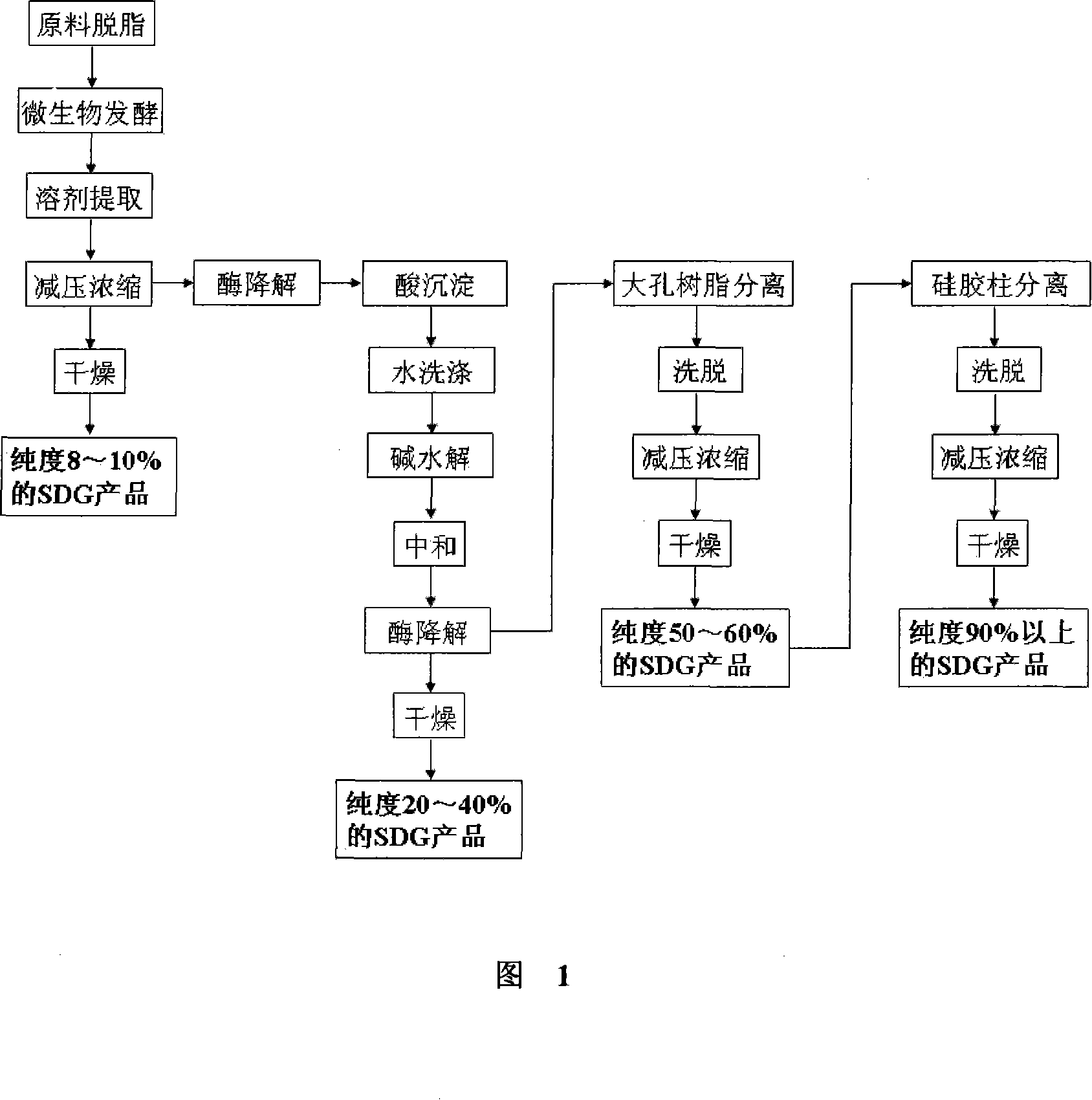

Method used

Image

Examples

Embodiment 1

[0065] Wet 100kg of defatted linseed cake with water, add yeast, ferment at 25±1°C for 48h; add 800L of ethanol solution with a volume concentration of 60%, extract at 60°C for 6h, extract twice in the same way, and wash with extraction solvent Filter cake 1 time; reclaim the solvent, dry to obtain 8.0kg of a product with a mass percentage of SDG of 9.5%;

[0066] The comparison group was extracted and dried by the same method as above, but no microbial fermentation treatment was carried out before extraction, and finally 7.2 kg of a product with a mass percentage of SDG of 5.3% was obtained.

Embodiment 2

[0068] Wet 100kg of defatted linseed cake with water, insert Bacillus, ferment at 37±1°C for 24h; add 800L of ethanol solution with a volume concentration of 70%, extract at 60°C for 6h, extract twice in the same way, and wash with extraction solvent Filter cake once; recover the solvent, and dry to obtain 8.8 kg of a product with a mass percentage of SDG of 8.9%.

[0069] The comparison group was extracted and dried by the same method as above, but no microbial fermentation treatment was carried out before extraction, and finally 8.0 kg of a product with a mass percentage of SDG of 6.0% was obtained.

Embodiment 3

[0071] Wet 100kg of defatted linseed cake with water, add mold, ferment at 28±1°C for 48h; add 800L of ethanol solution with a volume concentration of 70%, extract at 60°C for 6h, extract twice in the same way, wash and filter with extraction solvent Cake 1 time; recover the solvent and dry to obtain 10.5 kg of a product with a mass percentage of SDG of 9.8%.

[0072] The comparison group was extracted and dried by the same method as above, but no microbial fermentation treatment was carried out before extraction, and finally 7.6 kg of a product with a mass percentage of SDG of 5.5% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com