Method for preparing microcrystal hard WC-10% Co alloy

A cemented carbide and microcrystalline technology, applied in the field of powder metallurgy, can solve problems such as large particle size, widening of powder particle size distribution, and grain growth, and achieve the effects of fine grain, segregation prevention, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

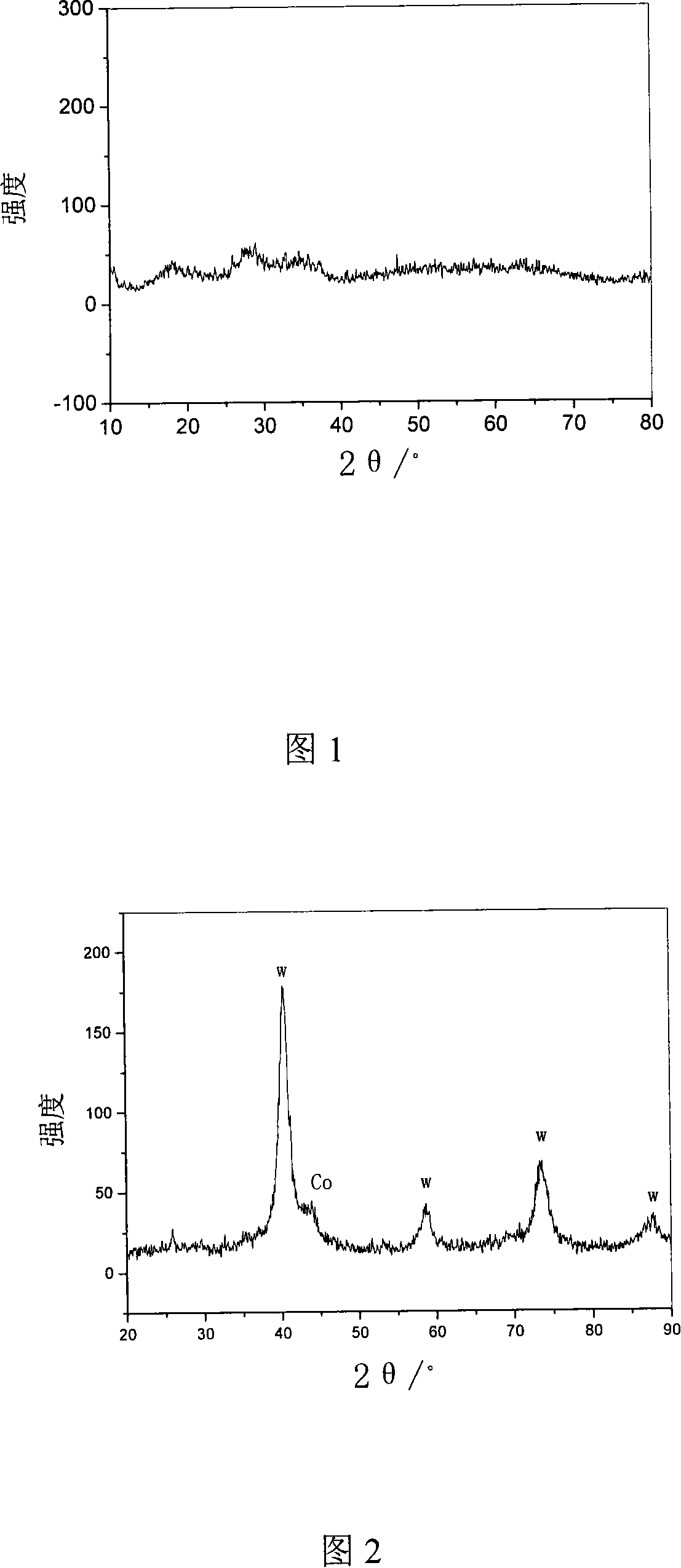

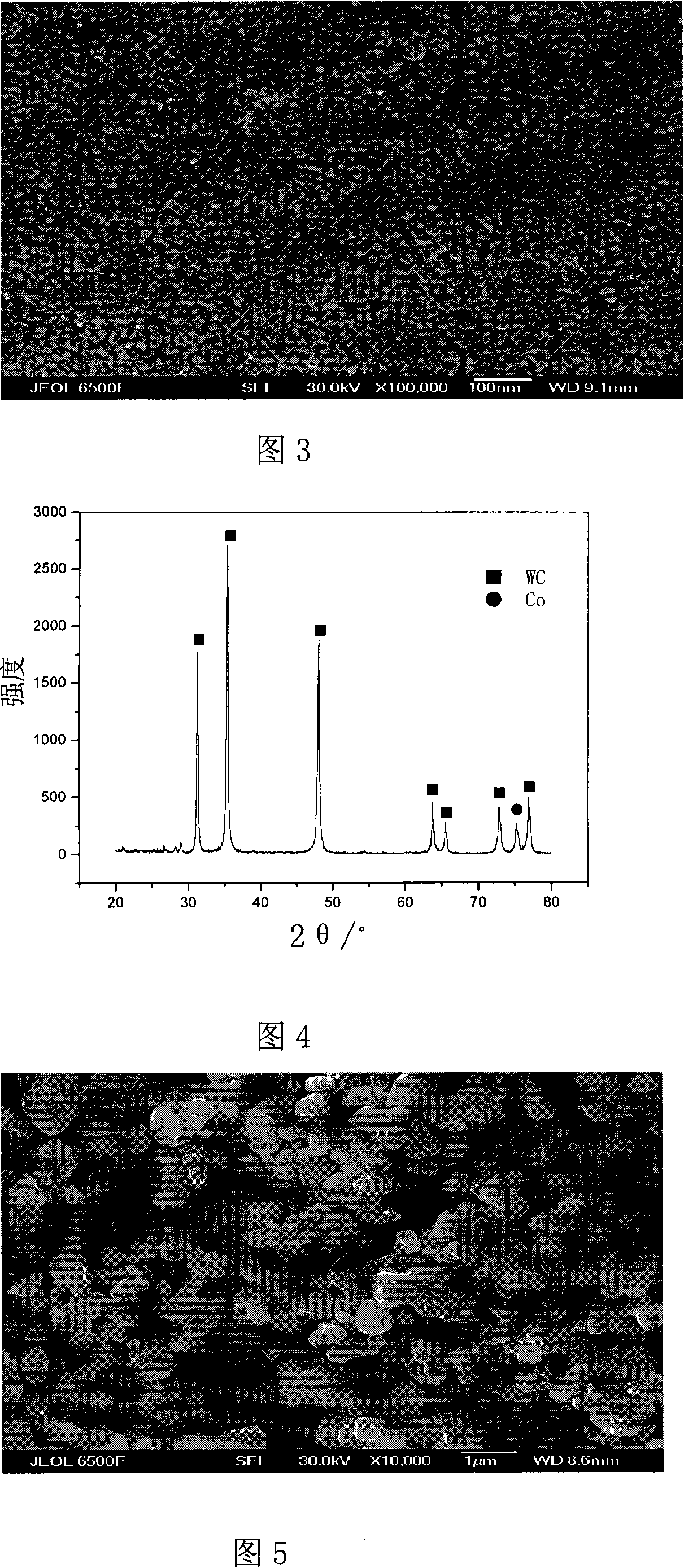

[0030] Example 1: 75.13 grams of ammonium metatungstate white crystal powder is dissolved in 1000 milliliters of water, another 28.70 grams of high cobalt red crystal powder of nitric acid is dissolved in 100 milliliters of water, after the two solutions are clarified, the two are mixed (wherein Co accounts for The weight percentage of W-Co mixed powder is 10.58%), to be clarified. Using a nitrogen spray gun with a gun pressure of 2 atm, disperse the clear mixed solution in liquid nitrogen. Then place the frozen material frozen in liquid nitrogen in the FTD Dura-stop MP type freeze dryer of FTS company for vacuum drying. 20°C; the working pressure is 150mtorr and the temperature is -15°C within 2700-3900 minutes; the working pressure is 50mtorr and the temperature is -5°C within 3900-4700 minutes; The working pressure is 0 millitorr and the temperature is 15°C; the freeze-dried mixed powder is subjected to secondary reduction, the obtained high cobalt nitrate is decomposed an...

example 2

[0032] Example 2: 56.34 grams of ammonium metatungstate white crystal powder was dissolved in 800 milliliters of water, and 21.52 grams of high-cobalt red crystal powder of nitrate was dissolved in 100 milliliters of water. After the two solutions were clarified, the two were mixed (wherein Co accounted for The weight percentage of W-Co mixed powder is 10.58%), to be clarified. Using a nitrogen spray gun with a gun pressure of 3 atm, disperse the clear mixed solution in liquid nitrogen. Then put the frozen material frozen in liquid nitrogen into the FTD Dura-stop MP type freeze dryer of FTS company for vacuum drying. 15°C; the working pressure is 200mTorr and the temperature is -10°C within 2700-3900 minutes; the working pressure is 100 mTorr and the temperature is -1°C within 3900-4700 minutes; The working pressure is 20 mTorr and the temperature is 28°C; the freeze-dried mixed powder is subjected to secondary reduction, the obtained cobalt nitrate is decomposed and hydrogen...

example 3

[0034] Example 3: 112.69 grams of ammonium metatungstate white crystal powder was dissolved in 1300 milliliters of water, and 43.05 grams of high cobalt red crystal powder of nitric acid was dissolved in 150 milliliters of water. After the two solutions were clarified, the two were mixed (wherein Co accounted for The weight percentage of W-Co mixed powder is 10.58%), to be clarified. Using a nitrogen spray gun with a gun pressure of 2.5 atmospheres, disperse the clear mixed solution in liquid nitrogen. Then put the frozen material frozen in liquid nitrogen into the FTD Dura-stop MP type freeze dryer of FTS company for vacuum drying. 18°C; the working pressure is 180 mTorr and the temperature is -13°C within 2700 to 3900 minutes; the working pressure is 80 mTorr and the temperature is -3°C within 3900 to 4700 minutes; The working pressure is 15 millitorr and the temperature is 20°C; the freeze-dried mixed powder is subjected to secondary reduction, and the obtained high-cobalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com