Barium zinc antimony based p type thermoelectric material and method for making same

A thermoelectric material, antimony-based technology, applied in the direction of thermoelectric device junction lead-out materials, etc., can solve problems such as low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

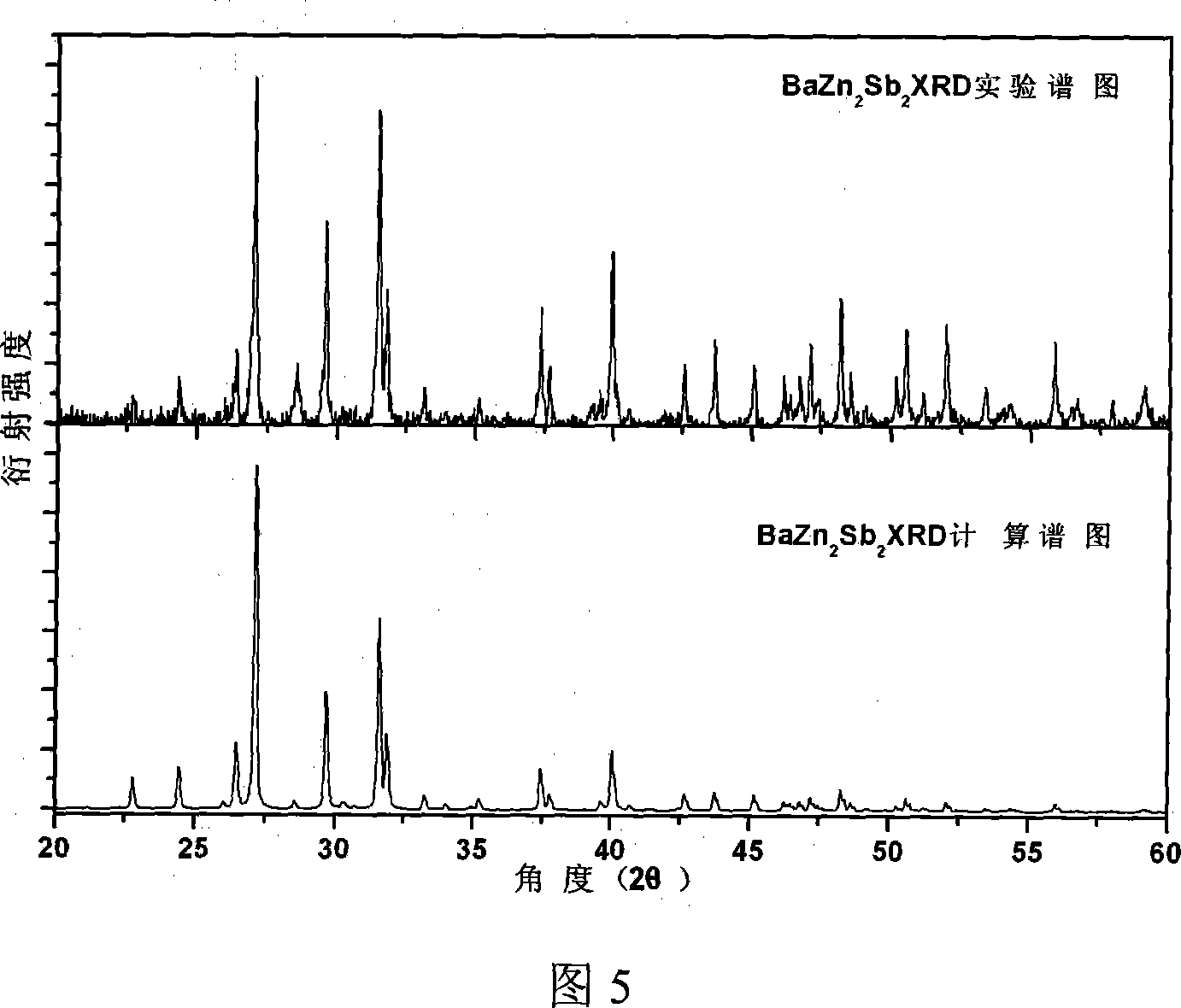

[0017] In the glove box, weigh 0.392g of Zn pellets (99.999%), 0.412g of Ba metal (>99%), and 0.731g of antimony pellets (99.999%), and put the raw materials into a 25mm container lined with carbon paper from bottom to top. ×Φ10mm size graphite crucible, then put this crucible into a quartz tube with an inner diameter of Φ11mm, plug it with a rubber stopper and take it out from the glove box. Then quickly evacuate it with a vacuum pump until the vacuum degree reaches 1×10 -6 When torr, it is sealed with a hydrogen-oxygen flame. Then put it into a heating furnace, raise the temperature to 800°C at a rate of 1°C / min, keep it warm for 72 hours, and take it out with the furnace cooling. The product was confirmed as BaZn by powder XRD 2 Sb 2Pure phase, Figure 5 shows the experimental and calculated XRD spectra. The obtained samples were ground into powder, and then sintered at 576° C., 50 MPa, and vacuum atmosphere for about 15 minutes by using rapid plasma sintering (SPS). Th...

Embodiment 2

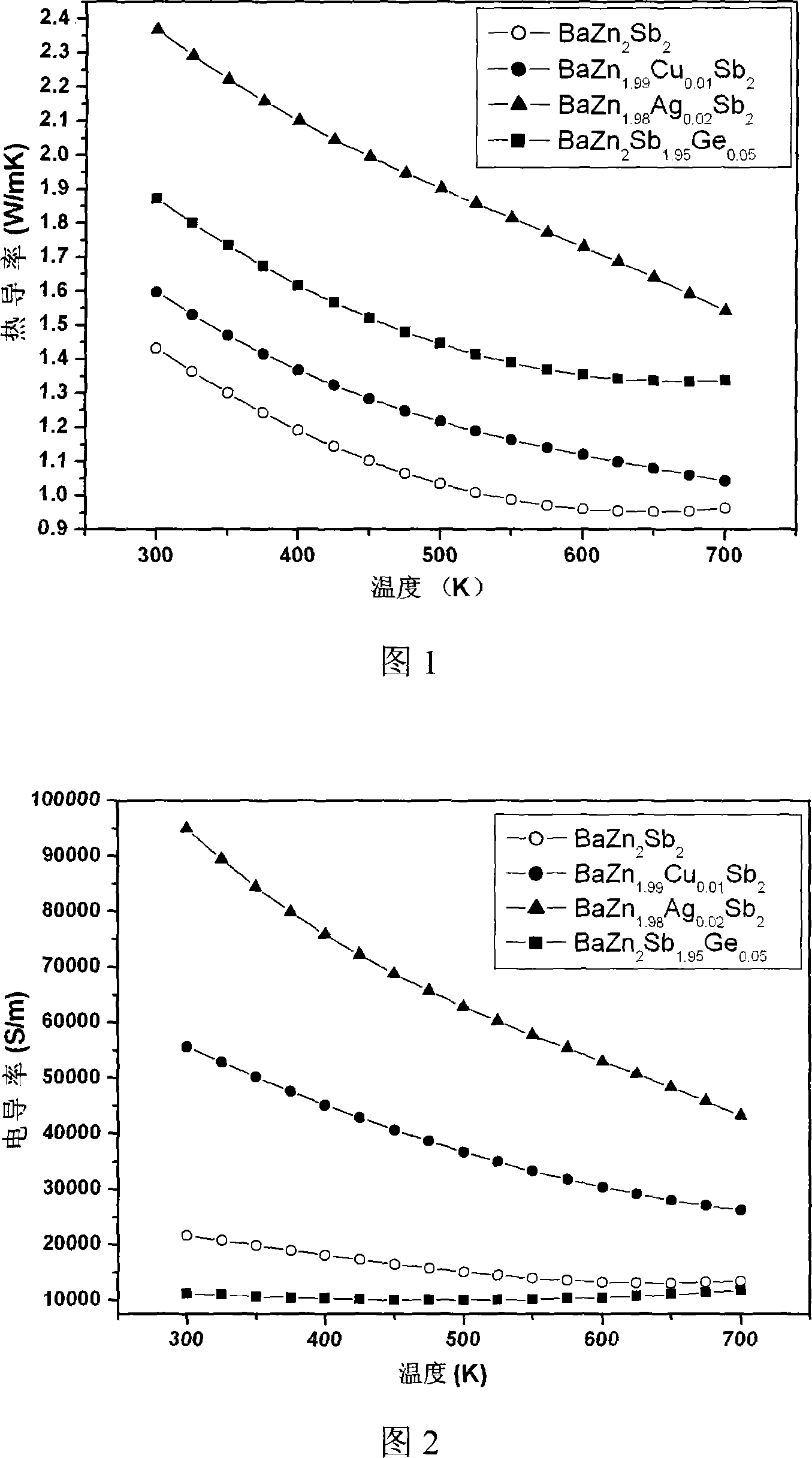

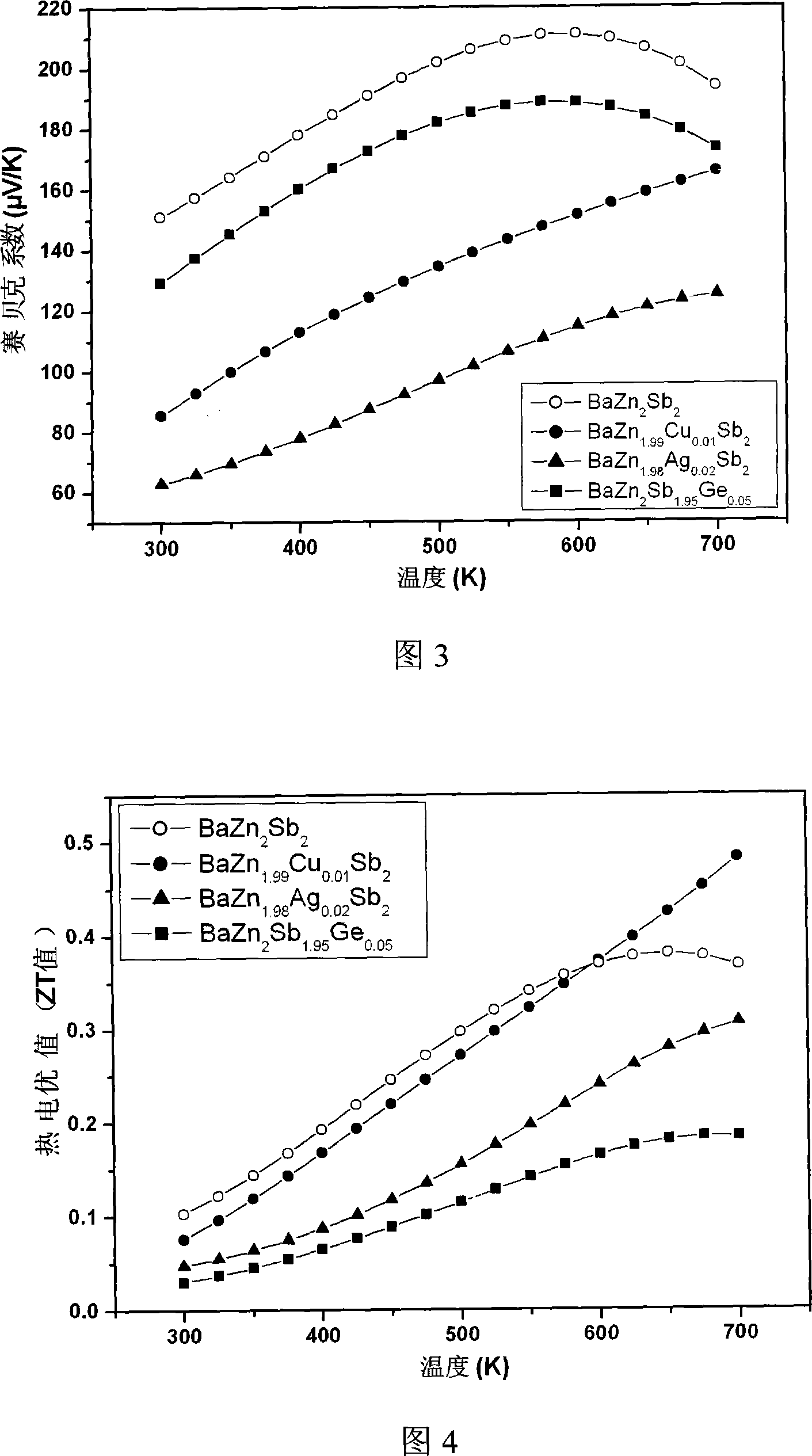

[0019] Take by weighing Zn particle (99.999%) 0.651g, Cu sheet (99.999%) 0.003g, Ba metal (>99%) 0.687g, antimony particle (99.999%) 1.218g, other conditions are the same as example 1, gained powder sample passes through Powder XRD detection confirmed as BaZn 2 Sb 2 Pure phase, SPS sintering temperature is 570°C, 50MPa, sintering in vacuum atmosphere for about 15 minutes. The density of the obtained ceramic sample is about 90%. Then the thermal conductance, electrical conductivity, Seebeck coefficient and thermoelectric figure of merit (ZT value) of the sample in the range of 300K-700K are tested. Figures 1, 2, 3, and 4 show the results, respectively.

Embodiment 3

[0021] Take by weighing Zn particle (99.999%) 0.777g, Ag (99.999%) 0.013g, Ba metal (>99%) 0.824g, antimony particle (99.999%) 1.461g, other conditions are the same as example 1, gained powder sample passes through powder XRD detection confirmed as BaZn 2 Sb 2 Pure phase, SPS sintering temperature 590°C, 50MPa, sintering in vacuum atmosphere for about 15 minutes. The density of the obtained ceramic sample is about 90%. Then the thermal conductance, electrical conductivity, Seebeck coefficient and thermoelectric figure of merit (ZT value) of the sample in the range of 300K-700K are tested. Figures 1, 2, 3, and 4 show the results, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com