Exhaust pipe for motorboat engine

A motorboat and engine technology, which is applied to engine components, machines/engines, propulsion engines, etc., can solve the problems of the motorboat's shell becoming soft, losing the function of driving, interfering with gas, etc., to reduce the number, intermediate Fewer links and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

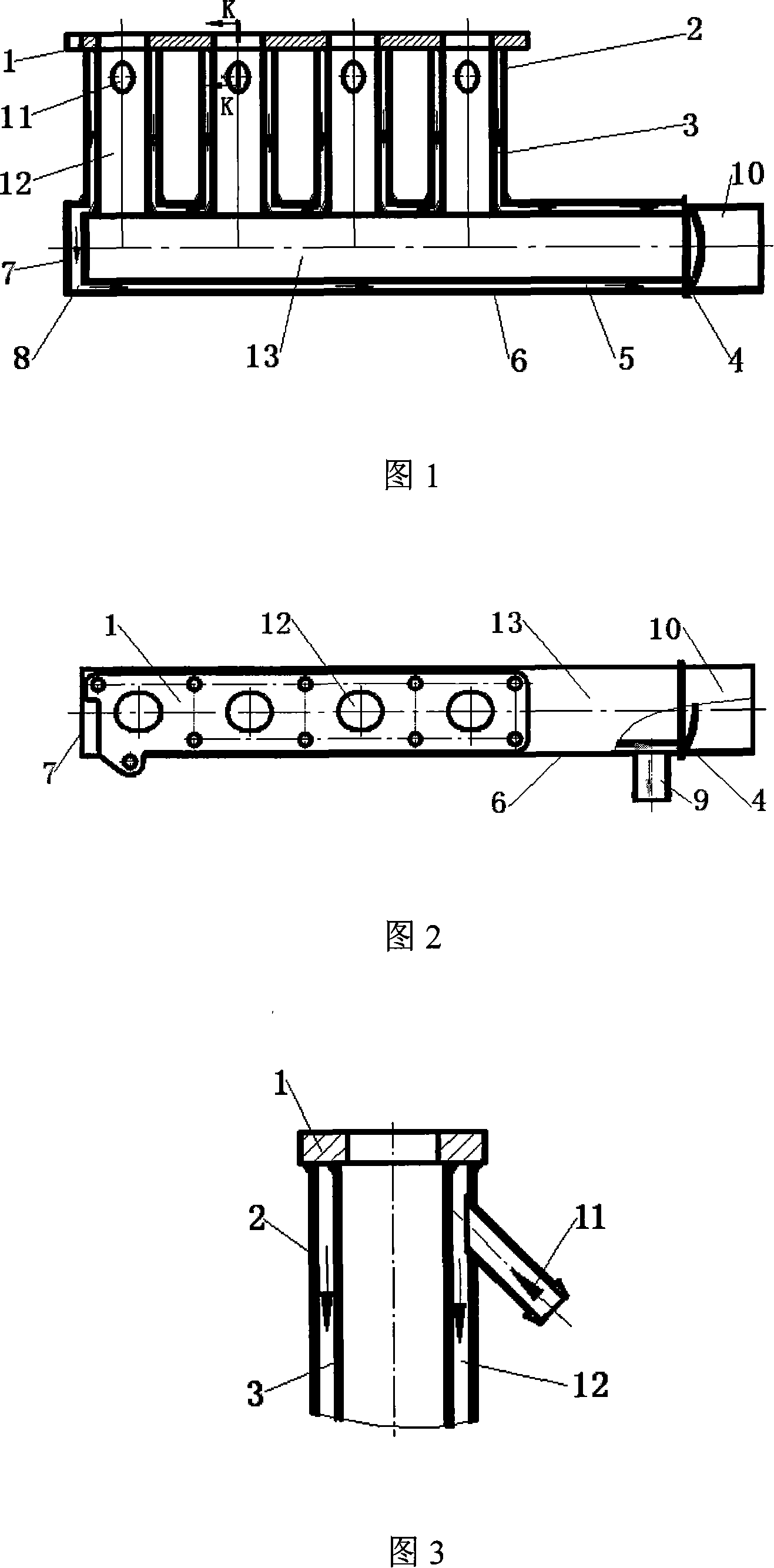

Embodiment 1

[0041] The nozzle of described exhaust tail pipe 10 stretches out of the hull of motorboat.

Embodiment 2

[0043] The nozzle of the exhaust tailpipe 10 is in the hull of the motor boat, and a water vapor collection box is arranged at the nozzle of the exhaust tailpipe 10 .

[0044] As shown in Figure 3, in order to make the water flow into the cavity to fill the inner cavity, the connection method between the water inlet port 11 and the outer pipe 6 of the main pipe is: the water inlet direction of the water inlet port 11 has a direction pointing to the connecting surface of the engine. slope. After the water flow enters, at first the exhaust pipe flange 1 with the highest temperature is fully cooled. The arrows in the figure indicate the direction of water flow.

[0045] To sum up, the exhaust pipe involved in the present invention adopts an inner and outer two-layer stainless steel exhaust manifold 12, an exhaust main pipe 13, four water inlet ports 11, one water outlet port 9, a sound-absorbing damping sheet assembly 4, and exhaust pipes. An assembly part welded by gas tail pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com