Method for preparing line shape or stick shape polycrystalline Ce0.6Zr0.3Y0.1O2 solid solution

A solid solution and rod-shaped technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve difficult problems such as high-temperature sintering of cerium and zirconium, affecting catalytic performance, etc. Achieve the effect of improving anti-poisoning ability, increasing service life and reducing poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

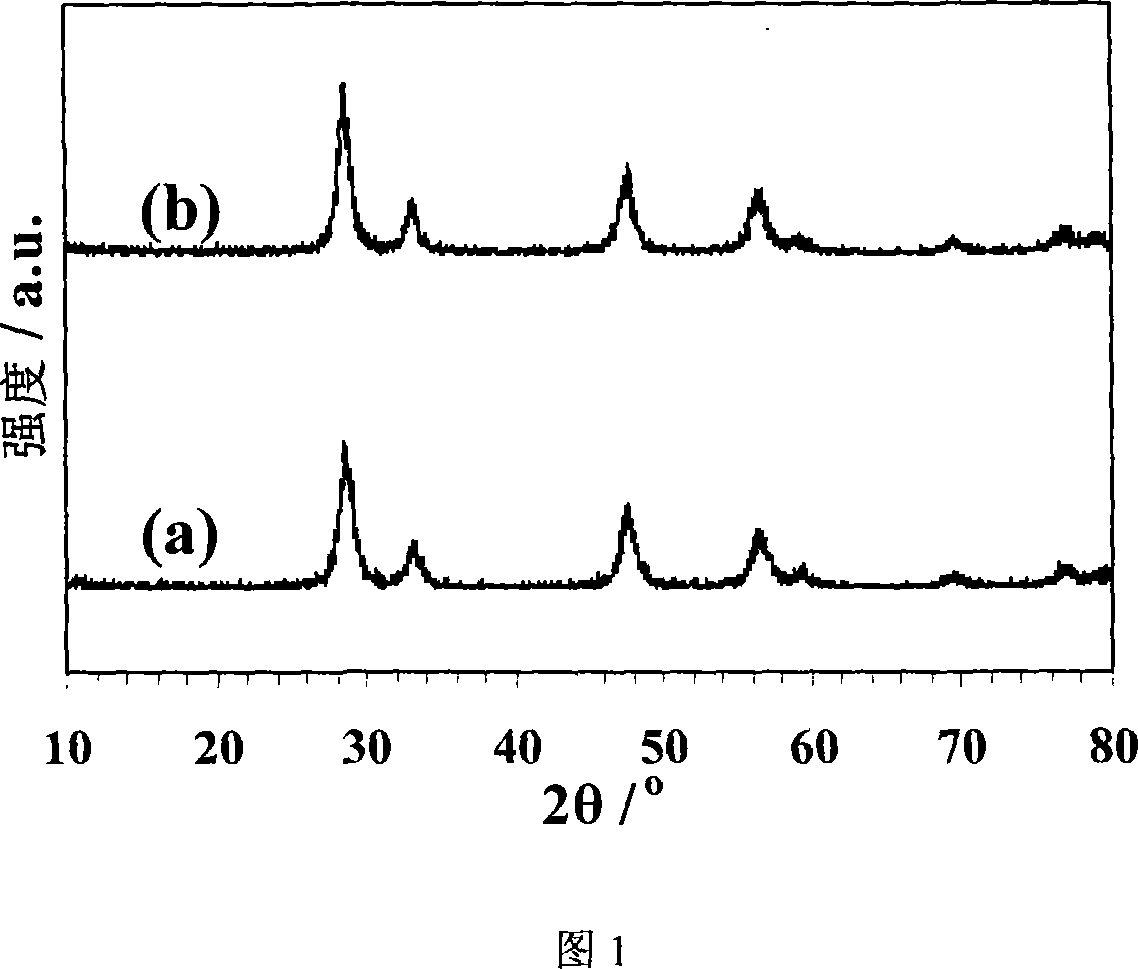

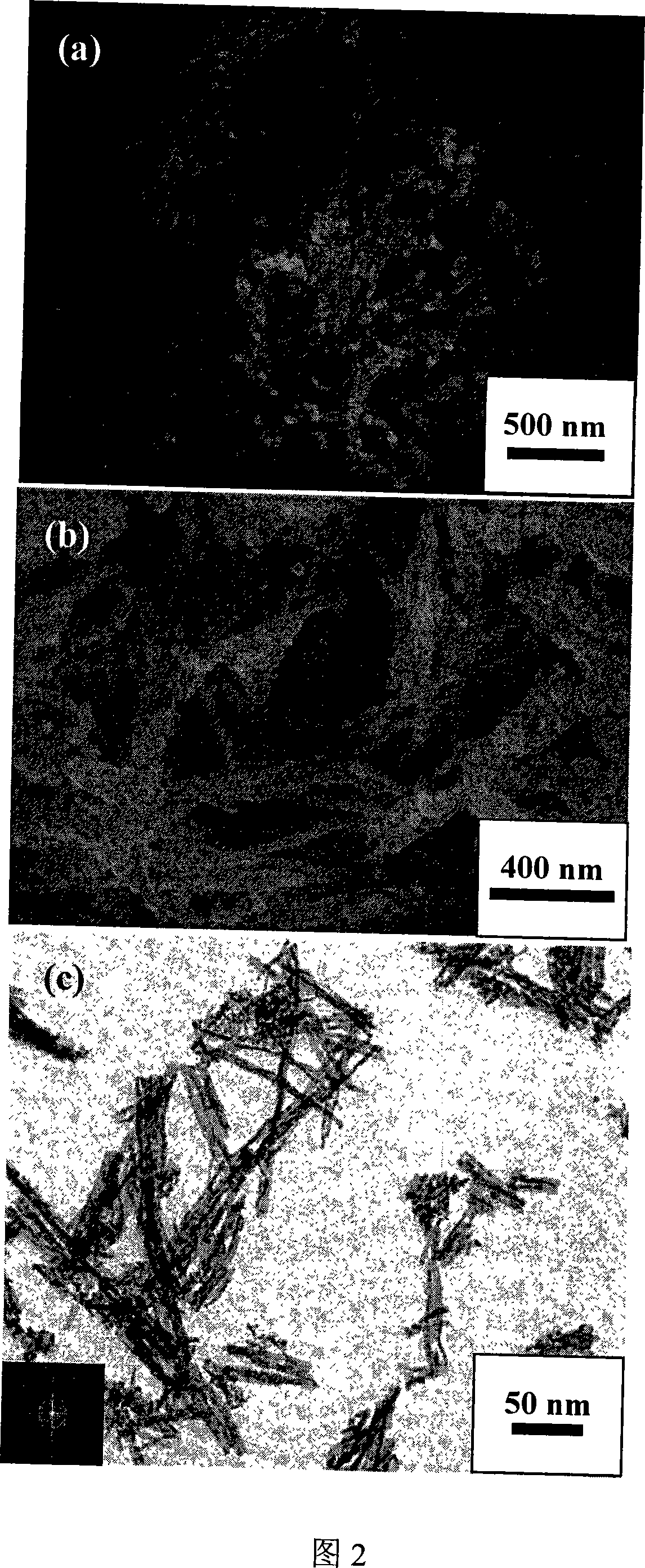

[0014] Example 1: Under normal temperature, normal pressure and magnetic stirring conditions, 7.278g CTAB was dissolved in 75ml deionized water, stirred and dissolved; 0.006mol Ce(NO 3 ) 3 .6H 2 O, 0.003mol ZrO(NO 3 ) 2 2H 2 O, 0.001molY (NO 3 ) 3 ·6H 2 O, dissolve in 5ml deionized water, stir to dissolve, add the above mixed solution containing cerium, zirconium and yttrium to the CTAB solution, then add 0.2mol urea to the solution, continue to stir for 2h, then transfer the above solution Put it into a stainless steel reaction kettle (60% volume filling) lined with polytetrafluoroethylene, then put it in a constant temperature box and keep it warm for 72h at 120°C, then cool naturally to room temperature, filter the obtained product, deionize and ethanol respectively After washing, drying, and grinding evenly, the target product precursor is obtained, and then the precursor is placed in a muffle furnace, and the temperature is raised to 550°C in an air atmosphere at a...

Embodiment 2

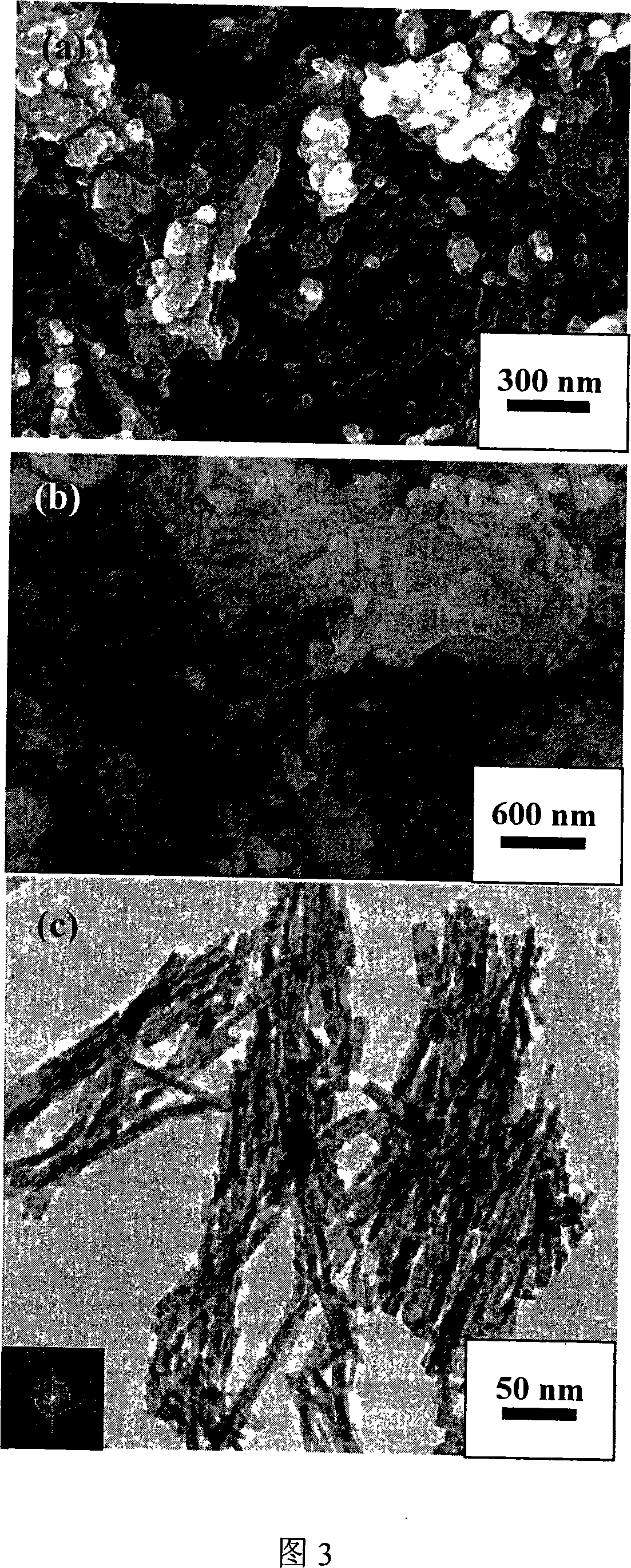

[0015] Embodiment 2: Obtain the solution according to Embodiment 1, transfer it to a stainless steel reaction kettle lined with polytetrafluoroethylene, put it into a constant temperature box and insulate it at 160°C for 72h, then cool naturally to room temperature, and the obtained product After filtration, deionization and ethanol washing, drying and grinding, the target product precursor was obtained, and then the precursor was placed in a muffle furnace and burned at a rate of 1 °C / min to 550 °C in an air atmosphere for 3 After h, the linear or rod-shaped polycrystalline Ce 0.6 Zr 0.3 Y 0.1 o 2 Solid solution, the length is 30nm ~ 2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com