System and method for producing furol by using agricultural and forestry castoff

A technology of agricultural and forestry waste and furfural, applied in the direction of organic chemistry, can solve the problems of unpublished furfural production process, insufficient conversion of pentose sugar, incomplete conversion of pentose sugar, etc., to increase yield, increase concentration, and solve pollution environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should be noted that these embodiments are only used to illustrate the method and equipment of the present invention, but not limit the scope of the present invention thereto.

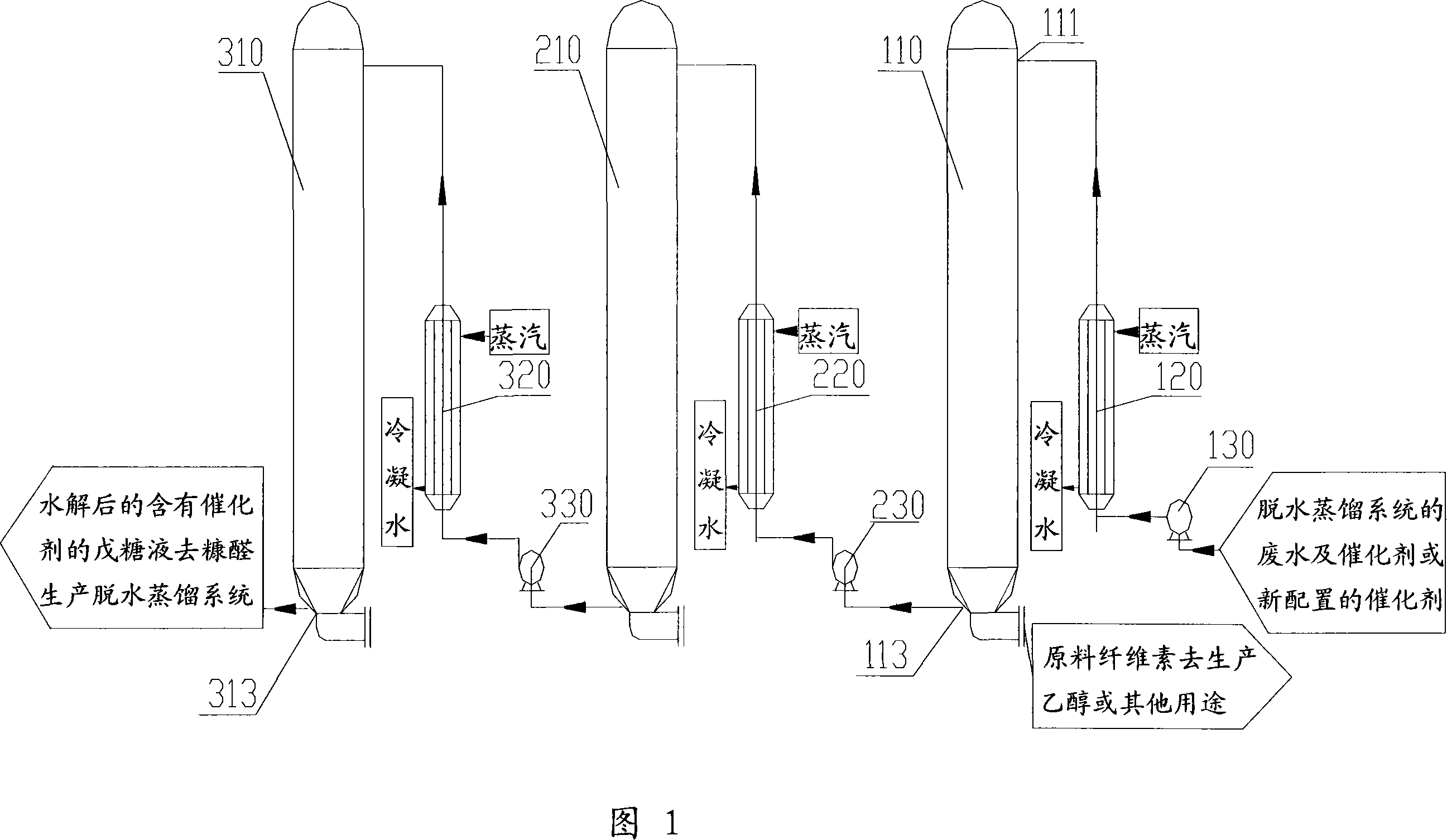

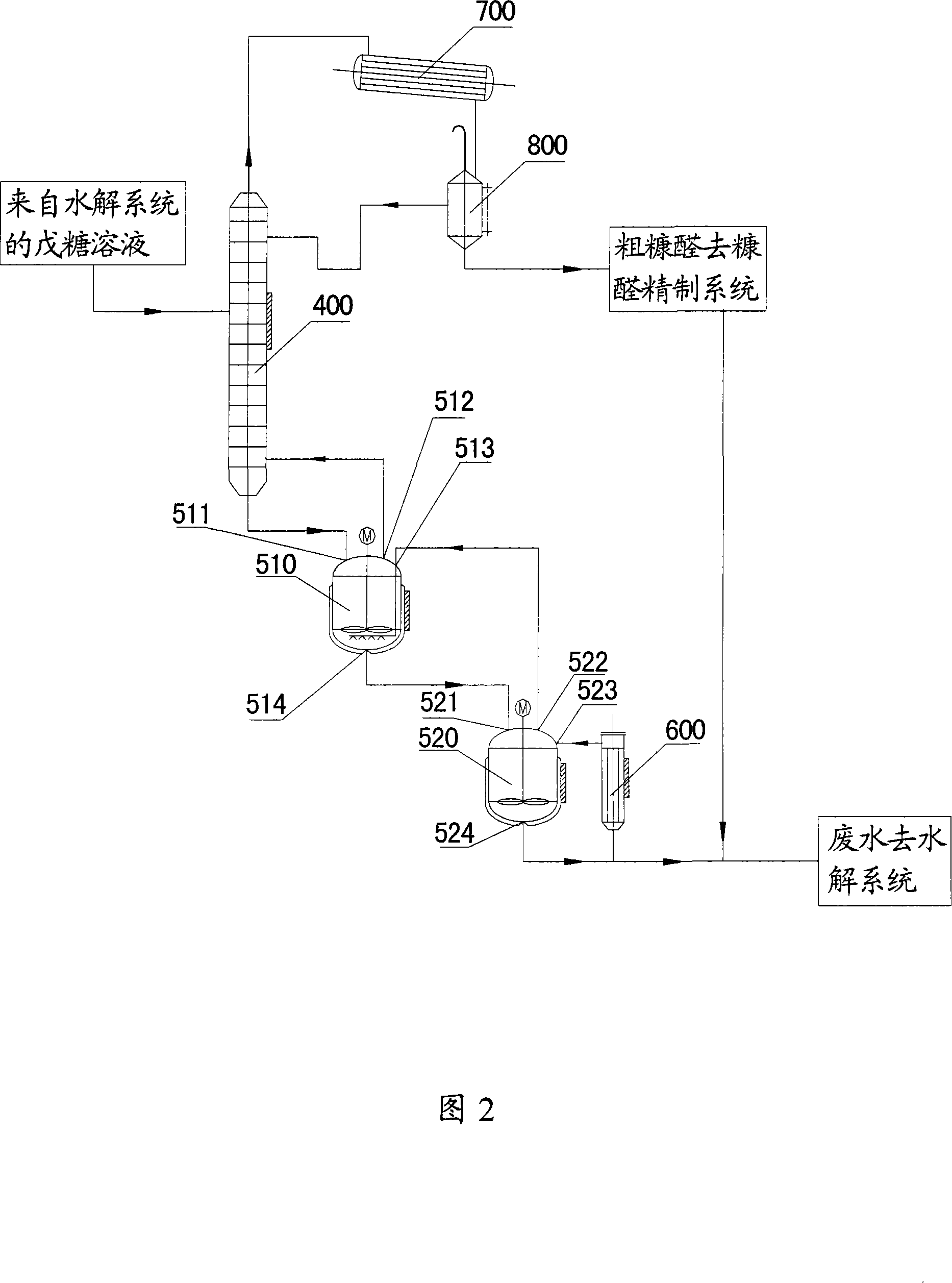

[0065] Whole large-scale system of the present invention is divided into hydrolysis system and dehydration distillation system below and discusses principle of the present invention respectively:

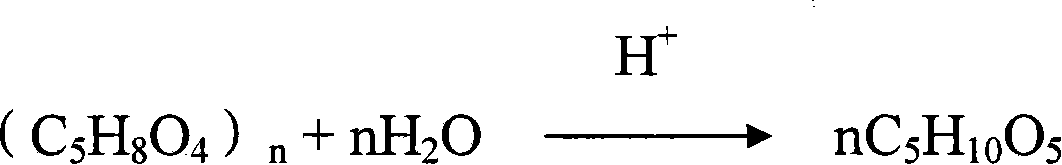

[0066] The first step is to introduce the principle of the hydrolysis system: the hydrolysis system is equipped with multi-stage end-to-end hydrolysis reactors, preferably 2-5 stages. After the raw materials in each stage of the hydrolysis reactor are filled, the first-stage hydrolysis reactor Continuously input the catalyst solution heated to the hydrolysis reaction temperature. After the catalyst solution stays in the first-stage hydrolysis reaction kettle for a certain period o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com