Solid composite micro-organism micro-balloon for organic contaminant biodegradation and method for preparing the same

A technology for compounding microorganisms and organic pollutants, applied in the field of solid composite microbial microspheres and its preparation, to achieve the effects of slowing migration, avoiding diffusion, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Surface culture: Phanerochaetechrysosoporium (purchased from China General Microorganism Culture Collection Center) was used as the fungus for the degradation of petroleum hydrocarbons. Prepare potato plane culture medium (PDA), inoculate Phanerochaete chrysosporium on the PDA plane culture medium, cultivate at 28°C for 6 days, and preserve for later use;

[0033] (2) Rinse the cultivated PDA plate with sterilized 20mMPBS (pH=7.0) to prepare a spore liquid with a concentration of 10 spores / ml;

[0034] (3) Sodium alginate-adsorbent solution is prepared, wherein the concentration of sodium alginate is 2%, and the adsorbent is selected to have a lignin biopolymer with strong absorption to phenanthrene, and the content is 5%;

[0035] (4) At normal temperature, uniformly disperse 800 mesh calcium carbonate particles in the solution described in (3), the concentration of calcium carbonate is 5%; then add the spore suspension obtained in (2) to the solution to make the s...

Embodiment 2

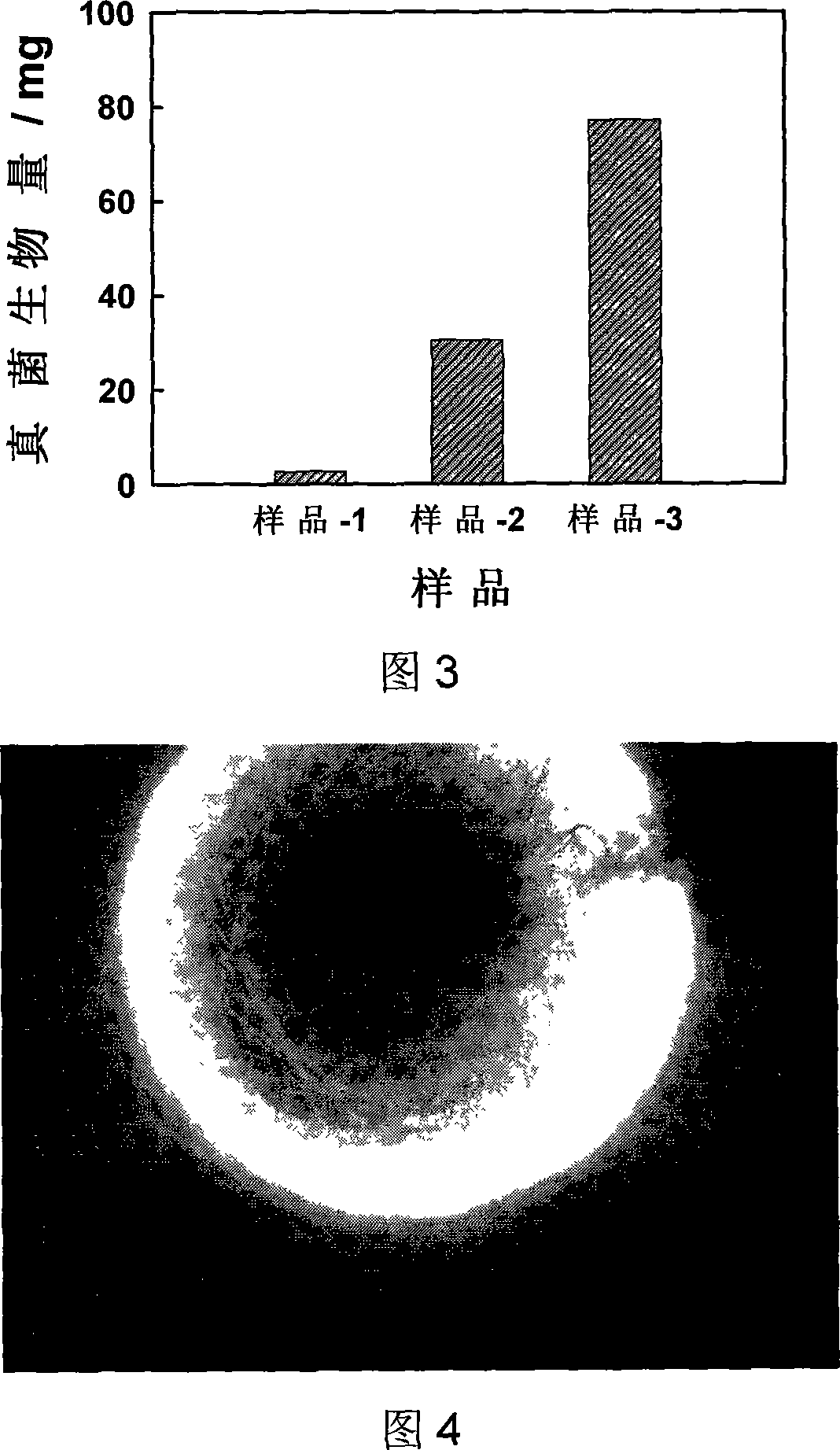

[0039] After the solid composite microbial microspheres obtained in Example 1 were placed at 30° C. for 24 hours, the free spores (sample one), the non-porous sodium alginate-embedded spores (sample two) and the samples obtained in Example 1 were compared by weighing method. The fungal biomass of the prepared solid composite microbial microspheres, the results (see Figure 3) show that the prepared solid composite microbial microspheres of the present invention can well promote the growth of fungi, and the 24h fungal biomass is respectively sample one and sample two 28.6 and 2.5 times. After culturing for 48 hours, the fungal morphology in the solid composite microbial microspheres prepared in Example 1 was observed under a microscope (as shown in FIG. 4 ).

Embodiment 3

[0041] Adsorption Kinetic Experiment of Organic Pollutant Phenanthrene

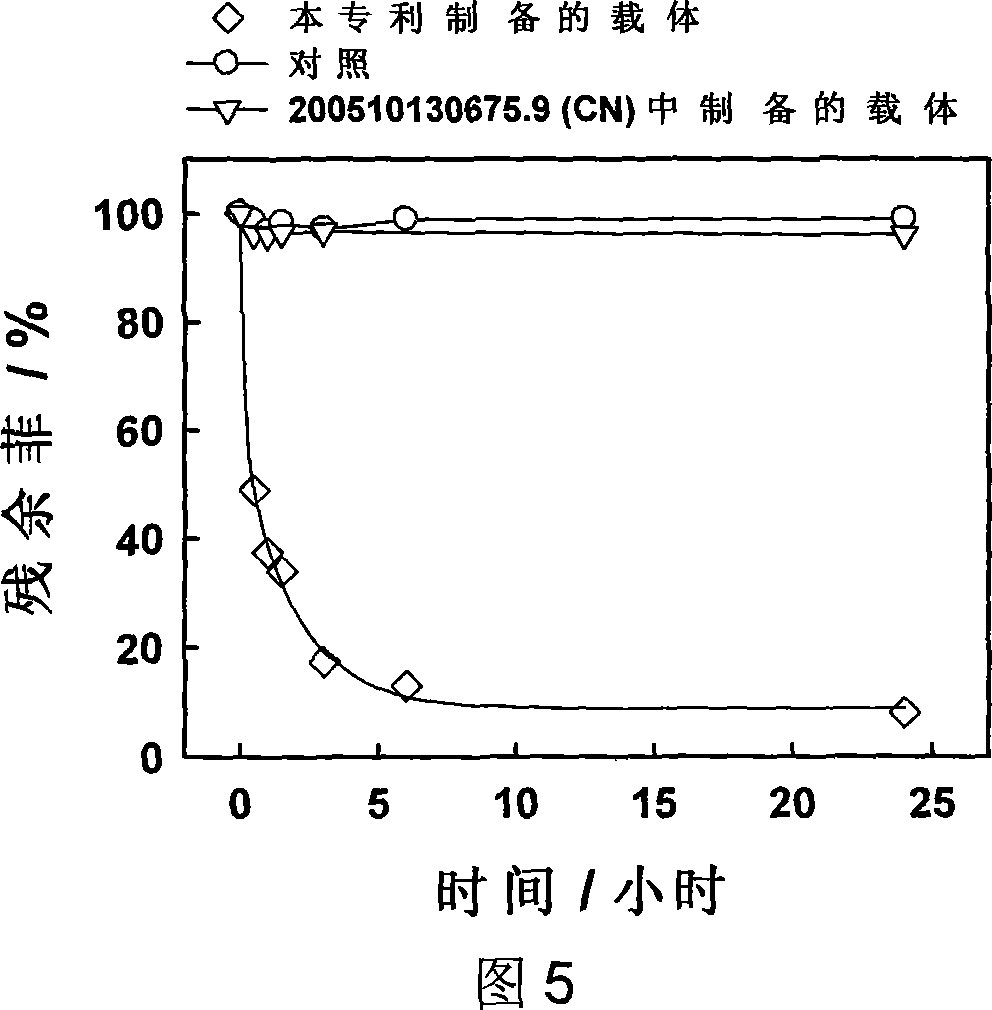

[0042] 0.4 g (wet weight) of solid composite microbial microspheres obtained in Example 1 was placed in 20 ml containing 5 mg / L phenanthrene, 200 mg / LTween80 and 200 mg / L NaN 3 In the 5mM PBS (pH=7.0) buffer solution (inhibiting the activity of embedded microorganisms), the adsorption kinetics of the carrier to the organic pollutant phenanthrene was investigated, wherein the contrast was the liquid phase system without adding any adsorbent, and according to the patent 200510130675.9 ( CN) made in only super large pores, does not contain the carrier of organic pollutant class adsorbent. Result (see Fig. 5) in the solution that adds the composite microorganism microsphere prepared in embodiment 1, residual phenanthrene content is 12% of initial phenanthrene content when 10h, illustrates that the carrier prepared by the present invention has good adsorption capacity to phenanthrene, However, the content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com