Complex effluvium waste gas purifying method

A waste gas and odor technology, applied in the field of waste gas treatment, can solve the problems of high cost and achieve the effects of low cost, strong water holding capacity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of complex malodorous gas comes from flotation tanks, sedimentation tanks, and sludge storage tanks. The malodorous gas often discharged contains cyclopentane; 2-methylpentane; 3-methylpentane; n-hexane; cyclohexane ; n-heptane; methylcyclohexane; 2-methylheptane; n-octane; C 8 Naphthene; C 9 ;n-butane; isopentane; carbopentane; n-pentane; carbohexaene; methylcyclopentane; 2-methylhexane; The above are collectively referred to as hydrocarbons with a content of 1 to 80g / m 3 .h, Alcohol 0~5g / m 3 .h, ester 0~6g / m 3 .h, ketones 0~10g / m 3 .h, aromatic 0~70g / m 3 .h, Nitrile 0~15g / m 3 .h, halide 0~6g / m 3 .h, hydrogen sulfide 0~10g / m 3 .h, organic sulfur 0~6g / m 3 .h is processed by biological filtration process.

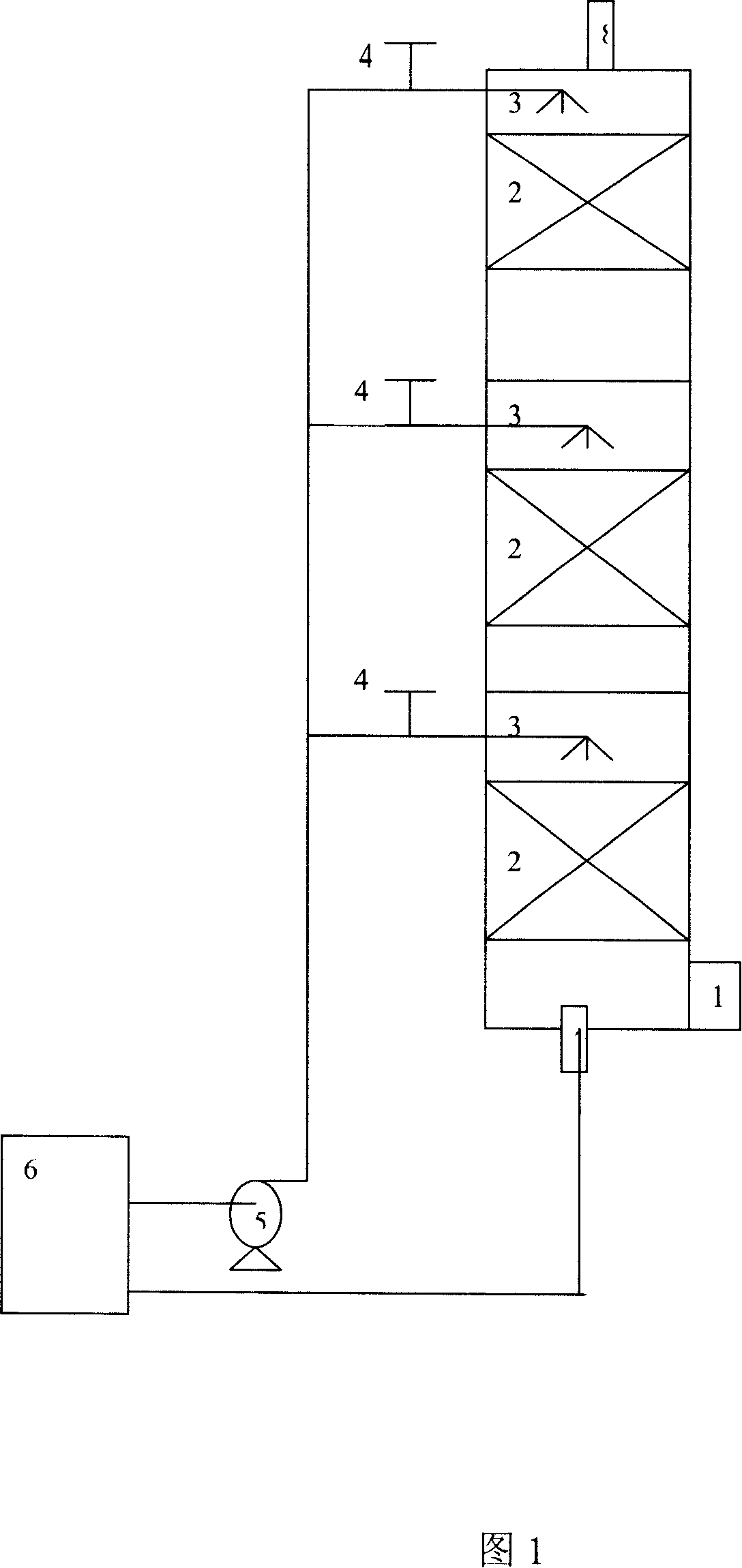

[0024] The filler of the packing tower is a mixture of bark, animal manure compost and volcanic rock, and its mixing weight ratio is bark: compost: volcanic rock=1: 0.4: 0.2, and the packing tower has a 3-layer structure, and the thickness of each lay...

Embodiment 2

[0030]The malodorous gas originates from coarse screens, grit chambers, regulating tanks, flotation tanks, aeration tanks, grease traps, sedimentation tanks, sludge storage tanks, and dehydration machine rooms, and the malodorous gas often discharged contains cyclopentane; 2 -Methylpentane; 3-methylpentane; n-hexane; cyclohexane; n-heptane; methylcyclohexane; 2-methylheptane; n-octane; C 8 Naphthene; C 9 ;n-butane; isopentane; carbopentane; n-pentane; carbohexaene; methylcyclopentane; 2-methylhexane; ; The above are collectively referred to as hydrocarbons with a content of 0-80g / m 3 .h Alcohols 0~10g / m 3 .h, ester 0~10g / m 3 .h, ketones 0~10g / m 3 .h, aromatic 0~80g / m 3 .h, Nitrile 0~15g / m 3 .h, halide 0~5g / m 3 .h, hydrogen sulfide 0~10g / m 3 .h, organic sulfur 0~6g / m 3 .h is processed by biological filtration process.

[0031] The filler of the packing tower is a mixture of bark, animal manure compost and volcanic rock, and its mixing weight ratio is bark: compost: vo...

Embodiment 3

[0036] The malodorous gas and the operating process are the same as in Example 1, and the operating temperature of the packed tower is 10-20°C. The filler of the packing tower is a mixture of bark, animal manure compost and volcanic rock, and its mixing weight ratio is bark: compost: volcanic rock=1: 0.2: 0.5. The packing tower has a one-layer structure, and the packing thickness is 2 meters. The purified gas meets the first-level emission standard allowed by the state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com