Layer stephanoporate gamma-aluminum oxide and preparation method and application thereof

A hierarchical porous alumina technology, applied in the preparation of alumina/hydroxide, alumina/aluminum hydroxide, nanostructure manufacturing, etc., can solve the problems of low purity and high cost of hierarchical porous γ-alumina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

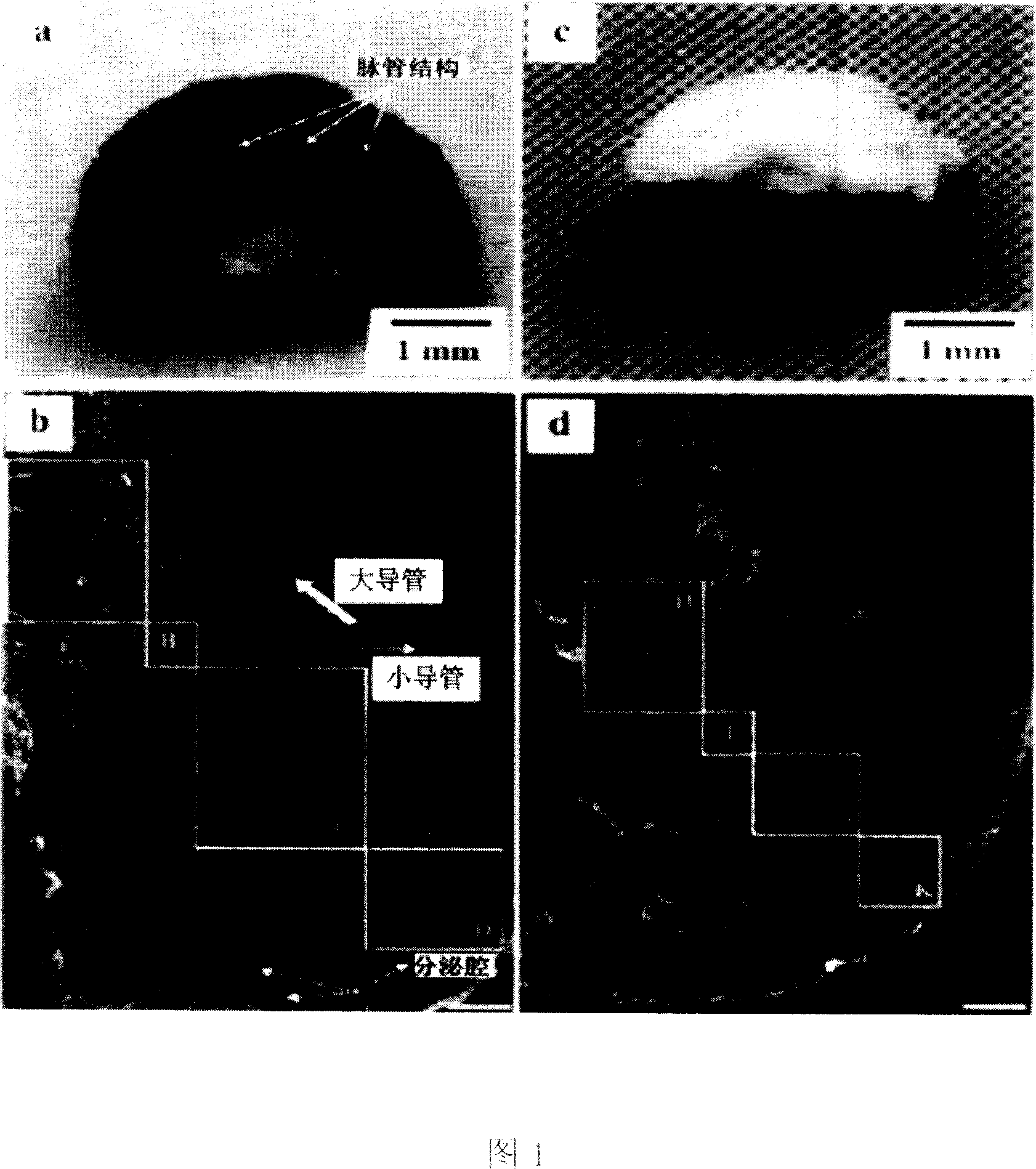

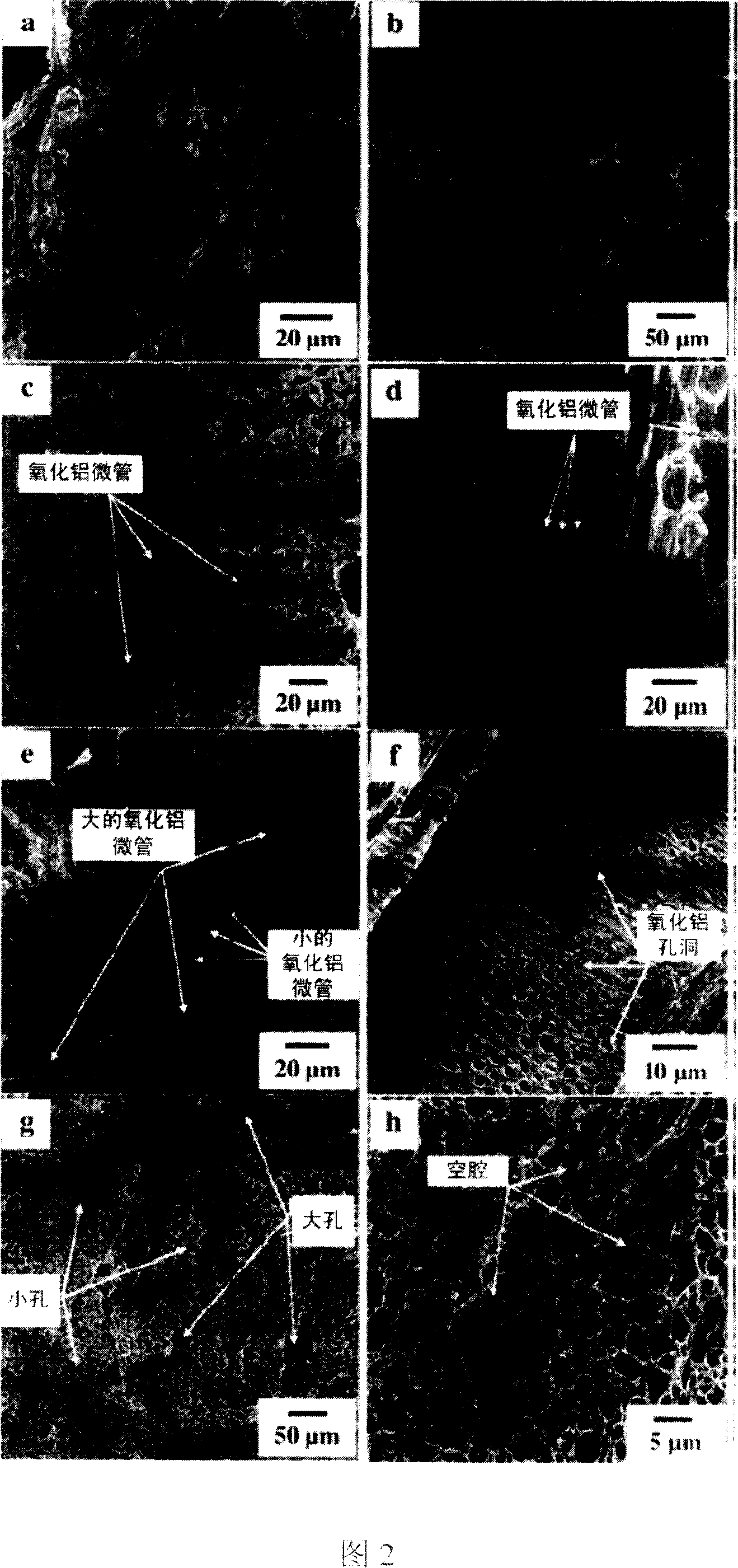

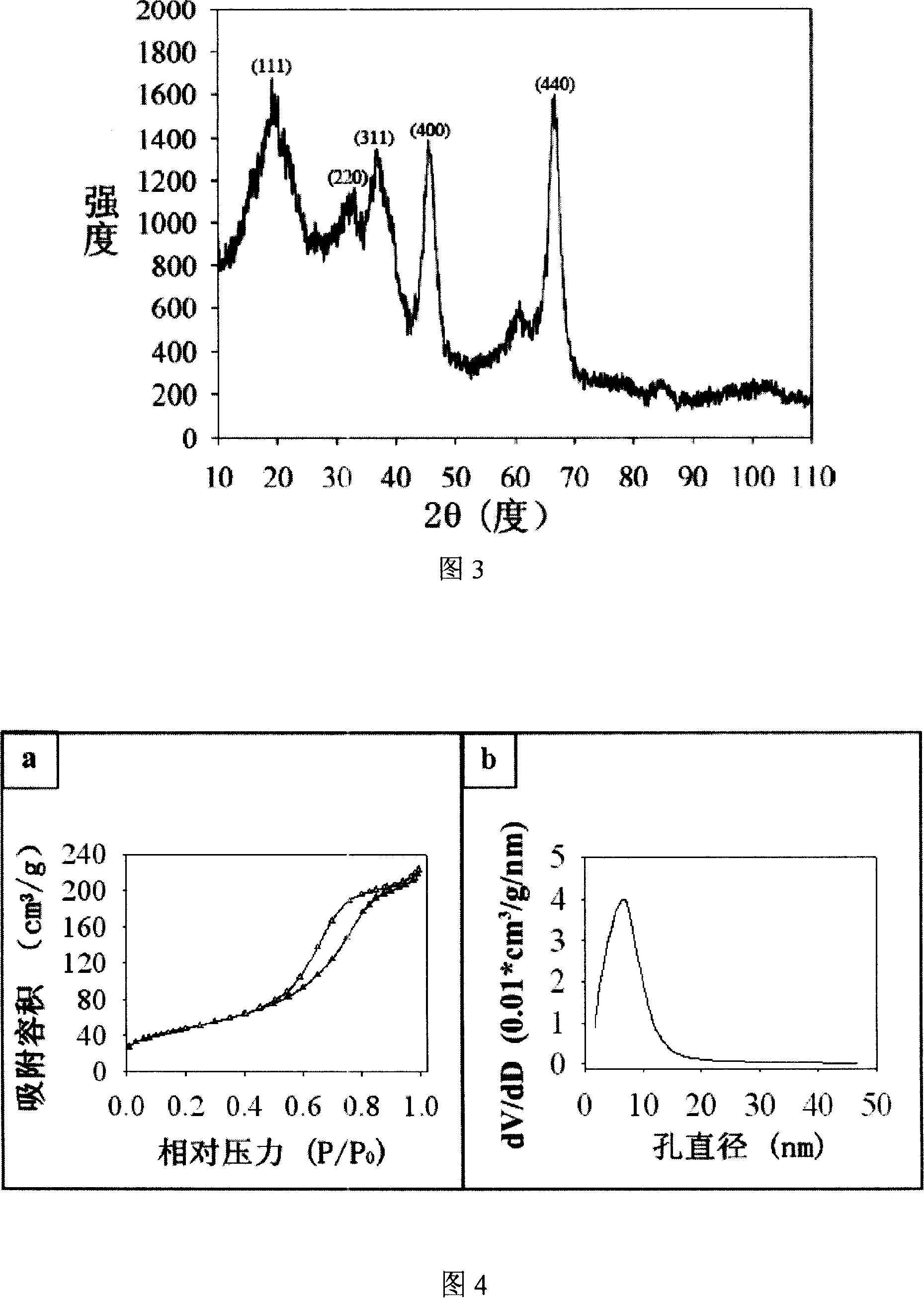

[0037] Take the stem of the wild plant Pueraria lobata as a template, peel it and cut it into slices; put the slices of Pueraria rhizome into 2.6 mol / liter nitric acid aqueous solution for 24 hours, and then wash it repeatedly with distilled water until the pH value of the washing solution is close to 7 , dried under vacuum at room temperature. The slices of the dried Pueraria rhizome were put into the aluminum chloride solution with a concentration of 1 mol / liter, soaked for about 70 minutes, then taken out and placed in the air for 6 hours. Put the kudzu rhizome slices loaded with the aluminum chloride solution into ammonia gas for about 3 hours and then dry them thoroughly at 50 degrees Celsius. Finally, it was calcined at 800°C for 4 hours, and the obtained white hierarchical porous γ-alumina sheet was shown in Figure 1 .

[0038] Figures 1a and 1b are the photographs and low-magnification scanning electron microscope images of cross-sections of Pueraria rhizomes treated ...

Embodiment 2

[0043] The hierarchical porous gamma-alumina sheet prepared according to Example 1 was immersed in 0.001 mol / liter of chloroplatinic acid solution for 10 minutes, then washed with absolute ethanol, and then immersed in an excess of 0.1 mol / liter of sodium borohydride The solution was reduced for 10 minutes, and then washed with distilled water. After vacuum drying, in situ supported reduced platinum nanoparticles were obtained on γ-alumina, and the results are shown in Fig. 5 . Figure 5 is a transmission electron microscope image of alumina loaded with platinum nanoparticles in situ. As indicated by the arrows in the figure, the white spots are alumina nanopores, the slightly darker gray part is the alumina support, and the darker spots all over the alumina are platinum nanoparticles.

Embodiment 3

[0045] Take 5 parts of hierarchical porous γ-alumina with in-situ loading of platinum nanoparticles in Example 2, 1 part of which is not annealed, and the other 4 parts are put into a tubular resistance furnace. , 700, 800 degrees Celsius annealing for 30 minutes. The layered porous γ-alumina loaded with platinum nanoparticles without annealing and annealed at 400, 600, 700, and 800 degrees Celsius were respectively ground into fine powder, and prepared into a turbid solution of absolute ethanol. Then transfer a small amount of turbid liquid to the copper grid used for the transmission electron microscope to carry the sample. After vacuum drying, observe on the transmission electron microscope. changes in temperature. From the observation results of the transmission electron microscope, the diameters of hundreds of platinum nanoparticles were counted, and it was concluded that the γ-alumina on the γ-alumina without annealing (at about 20 degrees Celsius) and at 400, 600, 700,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com