Method for preparing copper zinc aminoacetic acid complex by ball milling solid state

A solid-phase preparation, zinc glycine technology, applied in the preparation of organic compounds, chemical instruments and methods, cyanide reaction preparation and other directions, can solve the problems of serious environmental pollution, high production costs, complex processes, etc., and achieve less investment and reaction. The effect of short time and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

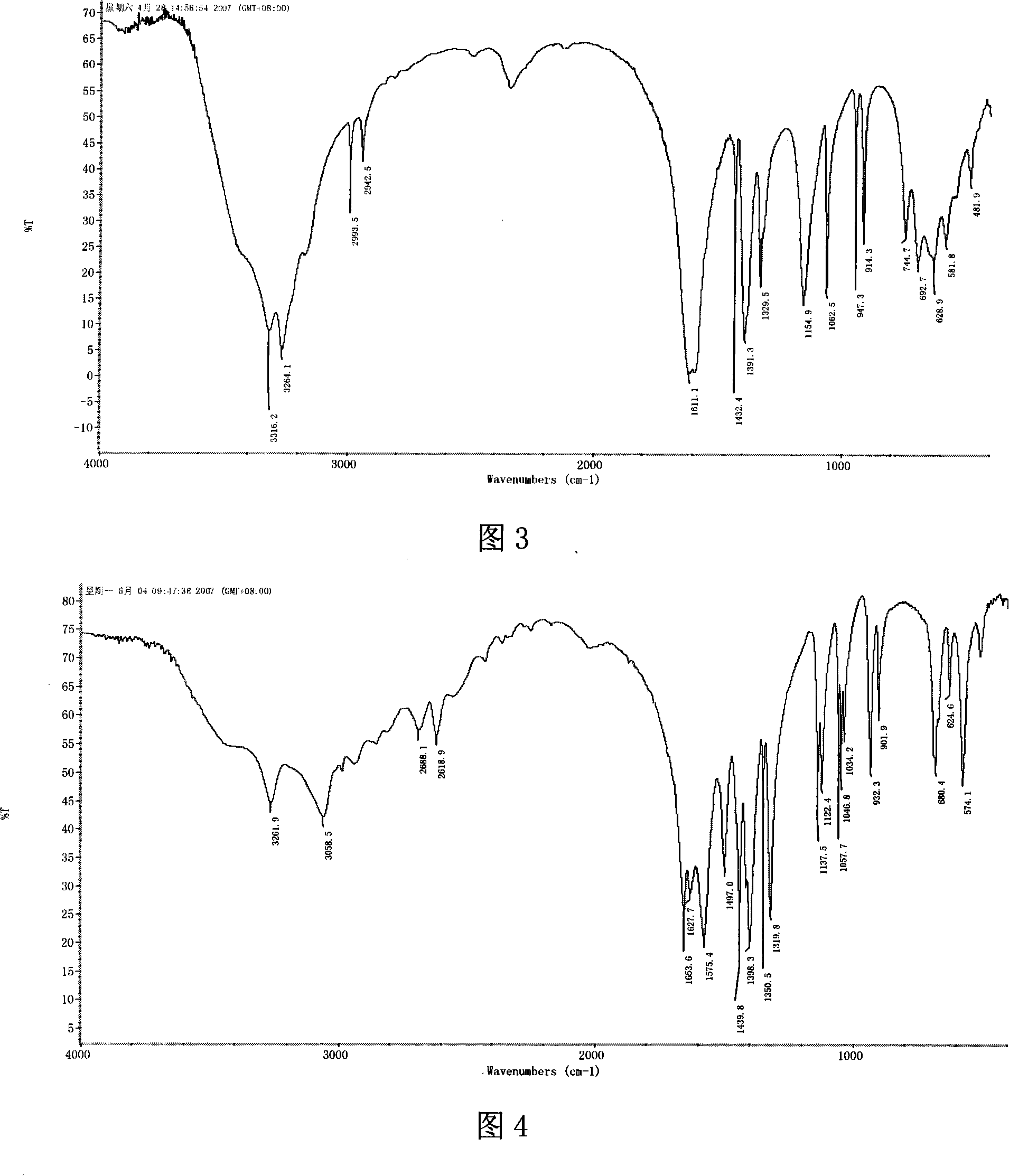

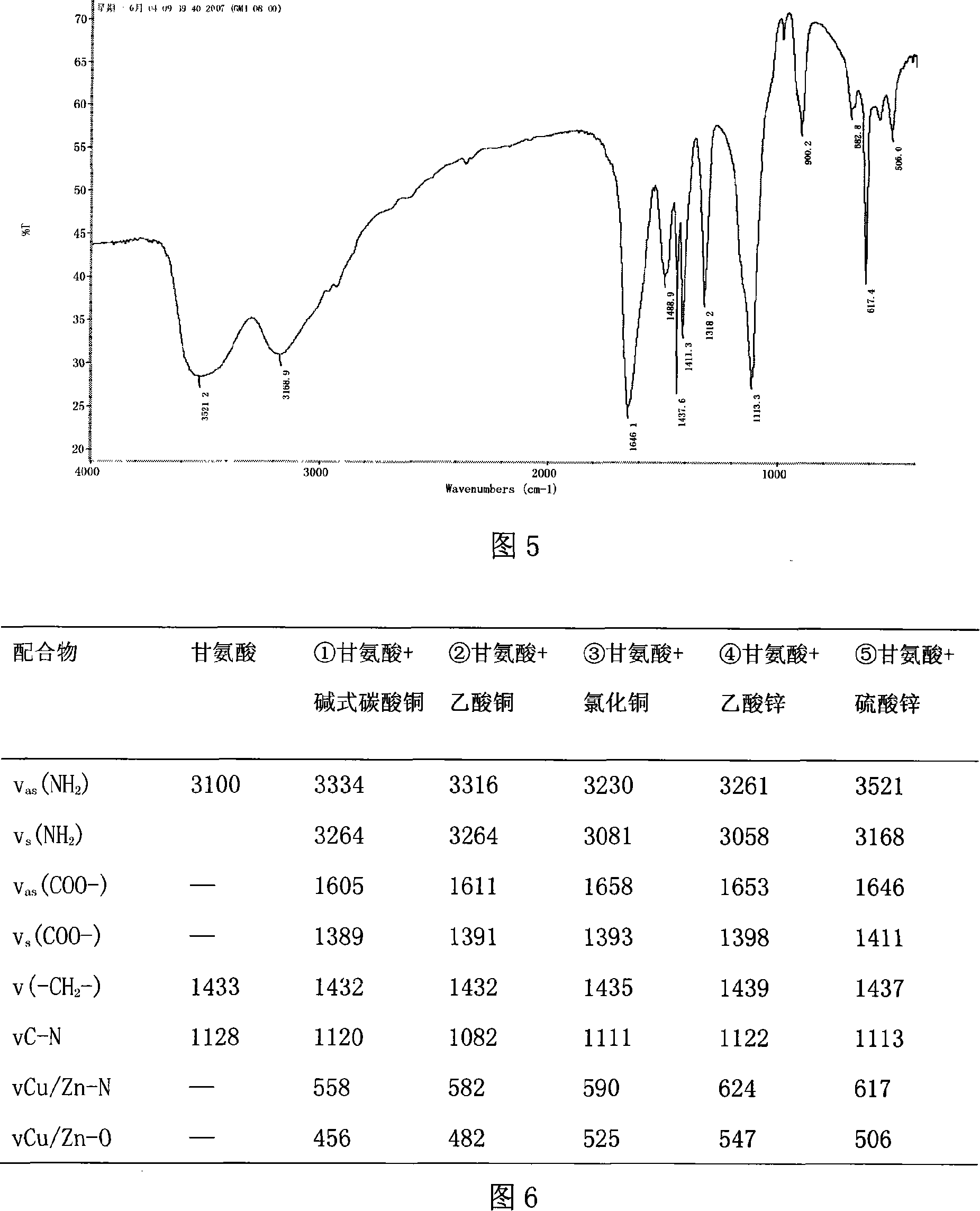

[0035] Example 1 Glycine and zinc acetate and glycine and copper acetate ball milling prepare zinc glycinate and copper glycinate. The reaction principle is:

[0036] 2NH 2 CH 2 COOH+Cu(Ac) 2 ·H 2 O→[Cu(NH 2 CH 2 COO) 2·H 2 O]+2HAc↑

[0037] 2NH 2 CH 2 COOH+Zn(Ac) 2 ·H 2 O→[Zn(NH 2 CH 2 COO) 2 ·H 2 O]+2HAc↑

[0038] The preparation steps are as follows: wash the ball milling tank and ball milling beads, and dry them in an oven; weigh glycine and copper acetate to make the molar ratio 2:1, weigh glycine and zinc acetate to make the molar ratio 2:1; add two Carry out ball milling in a ball mill tank with a rotating speed of 55r / min; after ball milling, glycine and copper acetate turn into a blue solid, with a small amount of water generated, and have a pungent smell of acetic acid; after ball milling, glycine and zinc acetate become a white solid with a small amount of Moisture is formed, and there is a pungent acetic acid smell; the ball milling time is 1.5h an...

Embodiment 2

[0043] Example 2 Glycine and zinc sulfate and glycine and basic copper carbonate prepare zinc glycinate and copper glycinate. The reaction principle is:

[0044] 2NH 2 CH 2 COOH+CuCO 3 ·Cu(OH) 2 ·H 2 O→[Cu(NH 2 CH 2 COO) 2 ·H 2 O]+3H 2 O+CO 2 ↑

[0045] 2NH 2 CH 2 COOH+ZnSO 4 5H2O→[Zn(NH 2 CH 2 COO) 2 ·H 2 O]+H 2 SO 4

[0046] Described glycine and basic copper carbonate and glycine and zinc sulfate prepare the steps of glycinate copper and glycinate zinc as follows: wash ball mill jar, ball milling beads, dry with oven; weigh glycine and basic copper carbonate, make its molar ratio be 4 : 1, weigh glycine and zinc sulfate, make its mol ratio be 2: 1; Add in two ball mill jars respectively and carry out ball milling with rotating speed as 55r / min; Glycine and basic copper carbonate ball mill become blue solid, have A small amount of water is formed; glycine and zinc sulfate become white solid after ball milling, and a small amount of water is formed, but t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com