Method for preparing hydroxypropyl chitose nano particle

A technology of hydroxypropyl chitosan and nanoparticle, which is applied in the field of preparation of hydroxypropyl chitosan nanoparticle, can solve problems such as non-normal degradation and harm to human body, and achieve easy industrial production, mild reaction conditions, and production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The invention uses chitosan with a degree of deacetylation greater than 90% as a raw material, reacts it with excess propylene oxide under alkaline conditions to generate water-soluble hydroxypropyl chitosan. Measure 5ml of 1.0mg / ml hydroxypropyl chitosan solution in a three-necked flask, and slowly add 0.8mg / ml sodium polyphosphate solution dropwise under continuous magnetic stirring at a rate of 20-40 drops / min , stop dropping after the solution presents obvious opalescence.

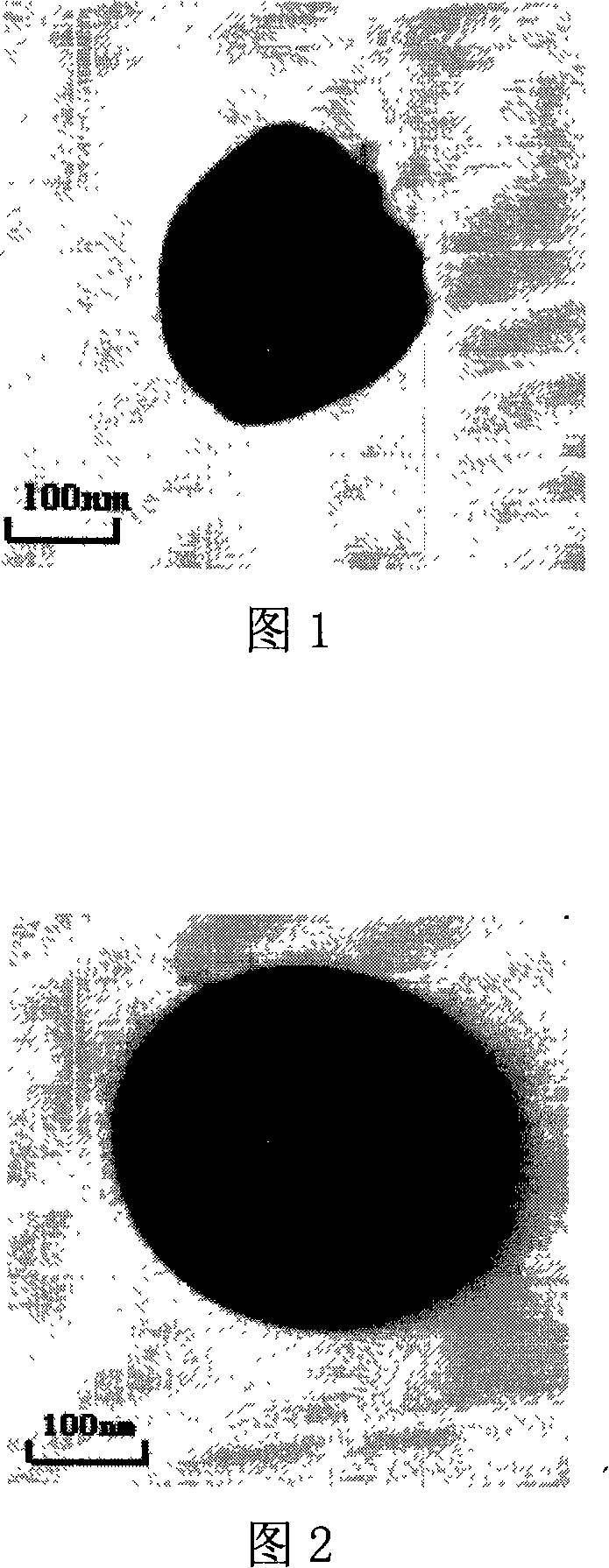

[0011] It can be seen from the transmission electron microscope photo in Fig. 1 that the shape of the hydroxypropyl chitosan nanoparticles is relatively regular spherical, and the particle size is about 240nm.

Embodiment 2

[0013] Measure 5ml of 2.0mg / ml hydroxypropyl chitosan solution in a three-necked flask, and slowly add 0.8mg / ml sodium polyphosphate solution dropwise under continuous magnetic stirring at a rate of 20-40 drops / min , stop dropping after the solution presents obvious opalescence.

[0014] It can be seen from the transmission electron microscope photo in Fig. 2 that the hydroxypropyl chitosan nanoparticles present a relatively regular spherical shape, and the particle size is about 360nm. The particle size in Example 2 is larger than that in Example 1, which is mainly due to the increase in the concentration of the reactant hydroxypropyl chitosan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com