Preparation method of standard sample for spectrum analysis

A technology of spectral analysis and standard sample block, which is applied in the field of preparation of standard sample block for spectral analysis, can solve problems such as loss, delay of analysis time, and large error in element content analysis, so as to reduce development cost, increase analysis time, and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

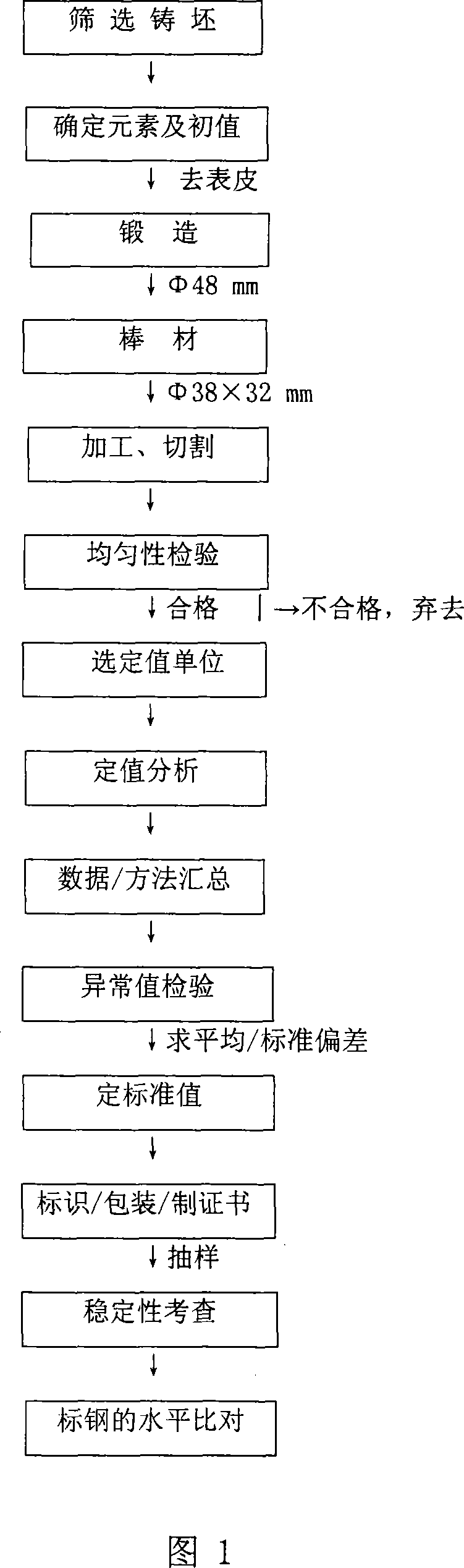

[0054] Below in combination with the accompanying drawings and according to the requirements of the national standard GB / T15000, briefly describe the process of the preparation method of the standard sample block for spectral analysis of the present invention and the use process of using the standard sample block for analysis and detection.

[0055] Proceed as follows:

[0056] 1. Screen steel grades

[0057] From the annual production of 7-8 thousand furnaces and nearly 100 steel types, the urgently needed continuous casting round billets are screened out. The length dimensions are about: Φ0.27×0.7m, Φ0.21×1.0m, and 10 steel types are selected. ; Namely: 27MnCrV, 26CrMo 4S / 1, 28CrMo 47 V, 2Cr 3 Mo, T91, 37Mn / 1, 27CrMo 27S , 20CrMo 4 , 42MnCr 62 V, 15CrMoG.

[0058] 2. Determine the initial value of elements and components required for each steel type

[0059] According to the product composition requirements, determine the main elements that need to be fixed for each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com