Laser micro processor optical focus system

An optical focusing and laser technology, applied in optics, optical components, laser welding equipment, etc., can solve the problems of high price, high processing precision, poor processing adaptability, etc., and achieve the effect of strong adaptability and large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

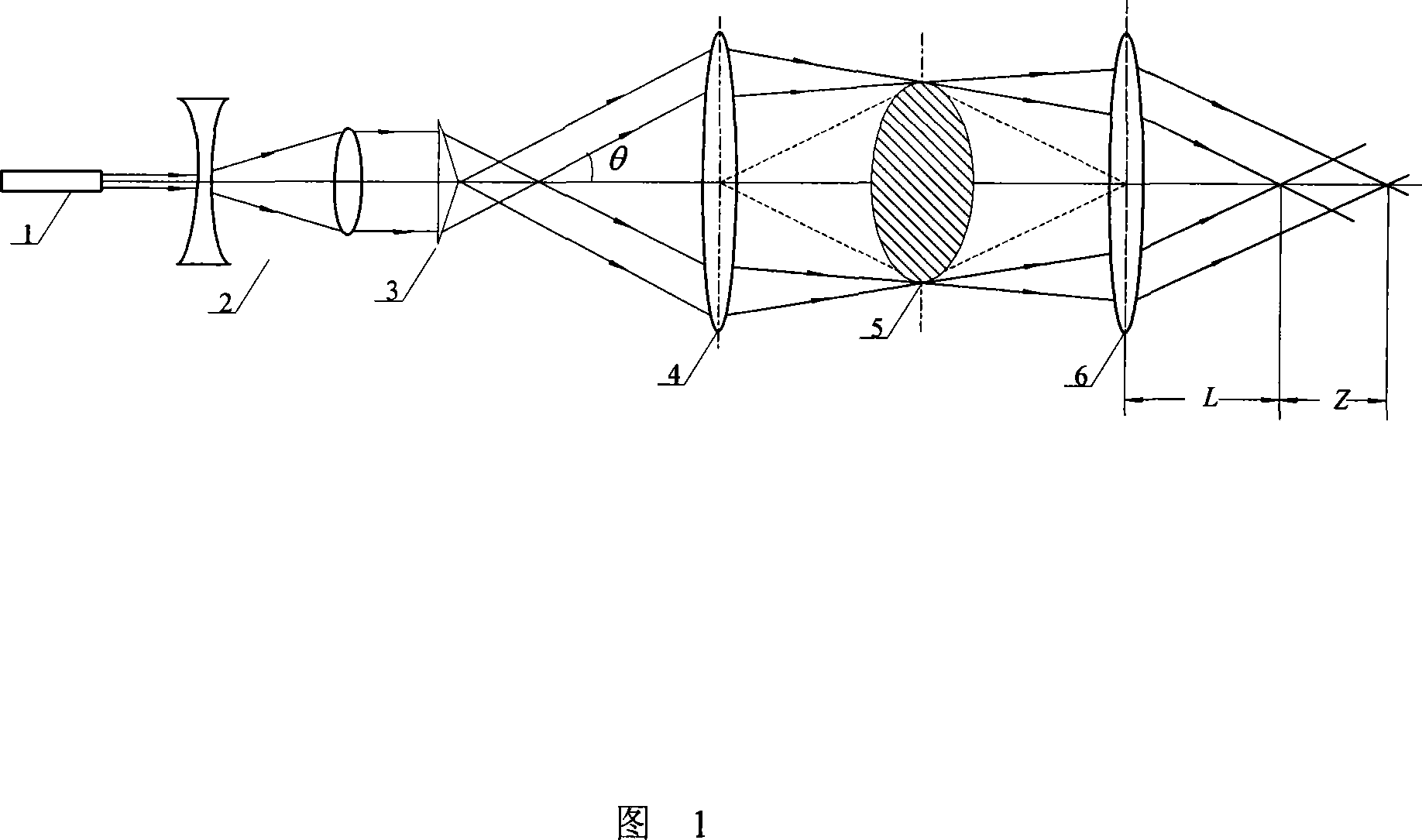

[0014] The details and working conditions of the design method proposed by the present invention will be described in detail below with reference to FIG. 1 .

[0015] The present invention includes a laser 1, a Galileo telescope 2, a positive rotating prism 3, a first spherical lens 4 and a second spherical lens 6. After the laser output beam generated by the laser 1 is expanded and collimated by the Galileo telescope 2, it is rotated positively. After the transformation of the prism 3, a group of conical wave vector plane waves diverged at the angle θ are generated. The focal plane coincides with the focal plane on the object side of the second spherical lens 6, and the thin ring is transformed by the lens 6 to generate a set of cone wave vectors with an included angle θ' to the Z axis. The convergence area is Z, and within the convergence area is an undiffracted beam.

[0016] Considering the misalignment sensitivity of the first spherical lens 4, the farther the light beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com