Hydrolysate enriched with biological bioactive peptide for accelerating beer yeast fermenting and its preparation method and application

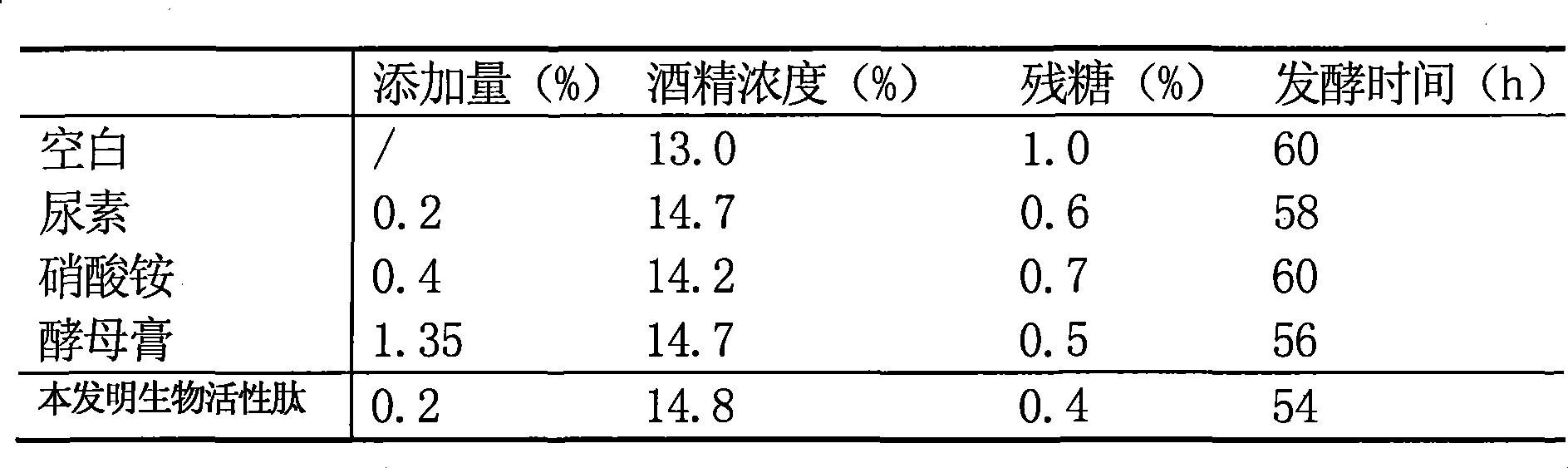

A bioactive peptide and brewer's yeast technology, which is applied in the field of hydrolyzates rich in bioactive peptides that promote fermentation of brewer's yeast, can solve the problems of low benefit and bioavailability, difficulty in breaking walls, and high residual sugar content, and improve production efficiency. and economic benefits, shorten the fermentation time, and reduce the effect of residual sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Mix 1 kg of Corynebacterium glutamicum and water in a 1:1 weight ratio, and stir evenly to prepare Corynebacterium glutamicum liquid;

[0024] (2) Adopt high-pressure homogenizer to carry out homogenization treatment to Corynebacterium glutamicum, 30MPa homogenization treatment 2 times;

[0025] (3) At 55°C, adjust the pH to 6.0 with sodium hydroxide solution, first use papain to hydrolyze, and use the pH-Stat method to control the degree of hydrolysis to 5.0%, then add chymotrypsin to hydrolyze, and use pH-Stat method to control the degree of hydrolysis to 10.2%, to obtain the enzymatic solution;

[0026] (4) Keep the enzymatic solution at 85°C for 18 minutes to inactivate the protease;

[0027] (5) Centrifuge the enzymatic solution at 6000r / m for 15min to remove the cell wall of Corynebacterium glutamicum;

[0028] (6) Pass the hydrolyzate through a 5000Da ultrafiltration membrane to remove large molecular weight polypeptides and proteins, and obtain an enzymati...

Embodiment 2

[0032] (1) each 1kg of Corynebacterium glutamicum and water are mixed, stirred evenly to prepare Corynebacterium glutamicum liquid;

[0033] (2) Adopting a high-pressure homogenizer to homogenize the Corynebacterium glutamicum liquid at 35MPa for 2 times;

[0034] (3) At 60°C, use sodium hydroxide solution to adjust the pH to 6.8, first use alkaline protease for hydrolysis, and when the degree of hydrolysis reaches 5.5% (pH-Stat method), add trypsin for hydrolysis, use pH-Stat method Control the degree of hydrolysis to 11.2% to obtain the enzymatic solution;

[0035] (4) Keep the enzymatic hydrolysis solution of (3) at 88°C for 15 minutes to inactivate the protease;

[0036] (5) Centrifuge the enzymatic solution at 6000r / m for 15min to remove the cell wall of Corynebacterium glutamicum;

[0037] (6) Pass the hydrolyzate through a 5000Da ultrafiltration membrane to remove large molecular weight polypeptides and proteins, and obtain a hydrolyzate rich in bioactive peptides tha...

Embodiment 3

[0039] (1) Mix Corynebacterium glutamicum and water in a mass ratio of 1:1 to prepare Corynebacterium glutamicum liquid;

[0040] (2) Adopt high-pressure homogenizer to carry out homogenization treatment to Corynebacterium glutamicum liquid, under the condition of 45MPa homogenization treatment 2 times;

[0041] (3) At 65°C, use sodium hydroxide solution to adjust the pH to 7.5, first use papain to hydrolyze, use the pH-Stat method to control the degree of hydrolysis to 5.8%, add trypsin for hydrolysis, and use the pH-Stat method to control the hydrolysis to 11.8%;

[0042] (4) Keep the enzymatic hydrolysis solution of (3) at 90°C for 15 minutes to inactivate the protease;

[0043] (5) The hydrolyzate was centrifuged at 6000r / m for 15min to remove the cell wall of Corynebacterium glutamicum;

[0044] (6) Pass the hydrolyzate through a 5000Da ultrafiltration membrane to remove large molecular weight polypeptides and proteins, and obtain a hydrolyzate rich in bioactive peptide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com