Method for treating fluoric containing drainage

A treatment method and wastewater technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve problems such as increased waste, calcium fluoride leakage, and unstable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

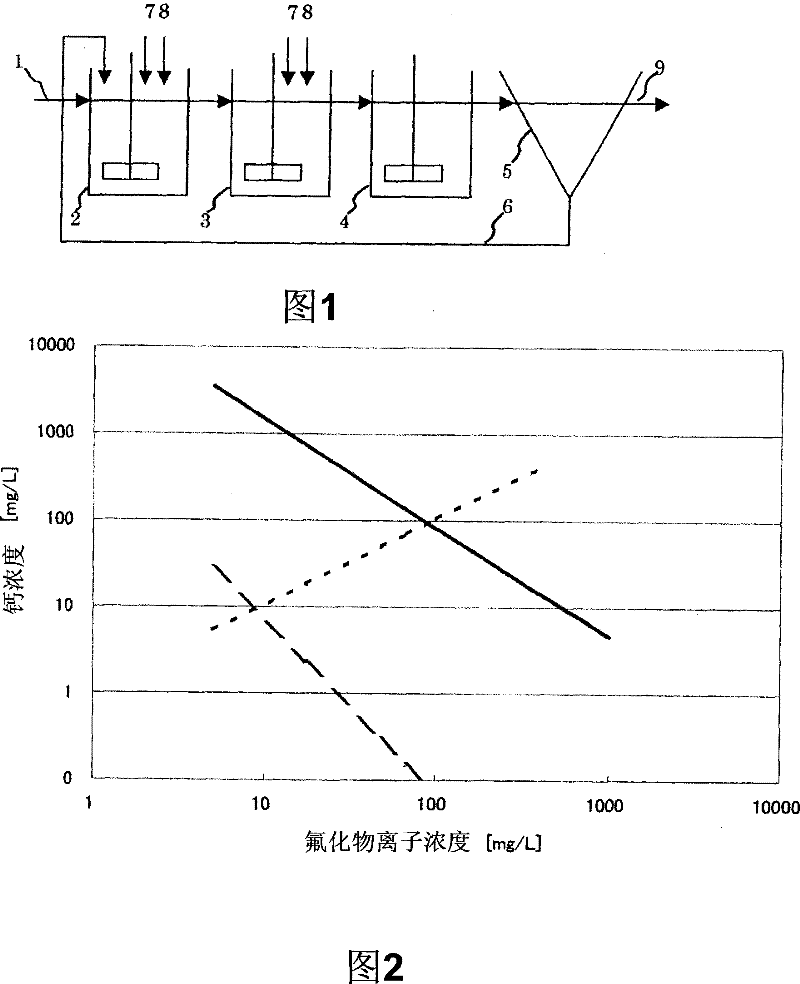

[0027] according to figure 1 The treatment process shown is to treat fluorine-containing wastewater.

[0028] Raw water quality is as follows.

[0029] PH: 3.4, F: 131mg / L, PO 4 3- -P: 1mg / L, SO 4 2- : 21.3mg / L, SiO 2 : 39mg / L, total organic matter (TOC): 3.3mg / L.

[0030] The capacities of the first reaction tank 2 , the second reaction tank 3 and the condensation tank 4 are 1 L respectively, and the capacity of the sedimentation tank 5 is 15 L. The flow rate of the above-mentioned raw water is 4L / Hr, and the amount of returned sludge is 0.1L / Hr. Calcium chloride was used as the calcium compound and added to the first reaction tank 2 and the second reaction tank 3, respectively. Regarding pH adjustment, the pH of the first reaction tank 2 and the second reaction tank was adjusted to 5±0.5 using 0.1N sodium hydroxide. The polymer coagulant is not added to the aggregation tank 4, and it is only used as a retention tank. In addition, at the start of the treatment, calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com