Method for preparing modified nano-stick array electrode after dispensing

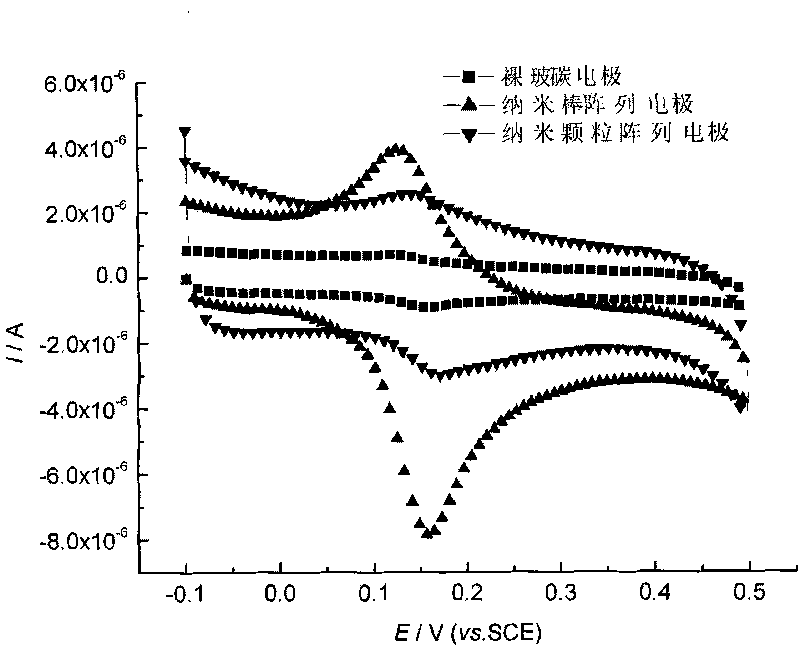

A nanorod array and nanorod technology, applied in electrodes, active material electrodes, electrolytic processes, etc., can solve the problems of underutilized electrode surface area and low signal-to-noise ratio of gold nanowire electrodes, and achieve rapid diffusion and mass transfer capabilities , Large electrode surface area, ultra-high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

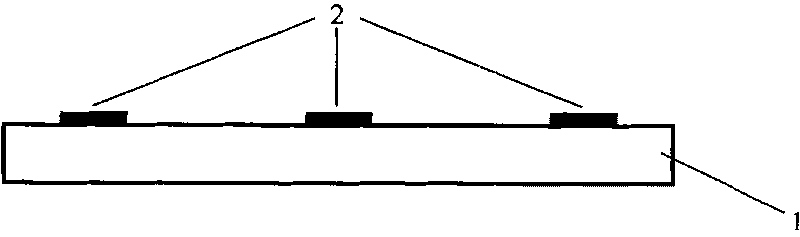

[0010] Embodiment 1: This embodiment consists of the following steps: 1. Dissolving the template of the metal nanorods grown by the template method, so that the nanorods can be manipulated freely; Fully disperse, avoid agglomeration, and form a dispersion solution of single nanorods; 3. By adjusting the concentration of nanorods in the dispersion solution, the nanorods can be modified on the surface of the substrate electrode with a controllable spacing.

[0011] The base electrode may be one of carbon, gold, platinum, silver or indium tin oxide (ITO) electrodes.

[0012] The various modification methods include coating, polymer material coating or electrodeposition and the like. A series of metal nanorods with controllable spacing are assembled on the substrate electrode by coating, polymer material coating, electrodeposition and other modification methods.

[0013] The metal nanorods are prepared by the template method, with a diameter of 2-250nm (optimally 10-100nm), and a...

specific Embodiment approach 2

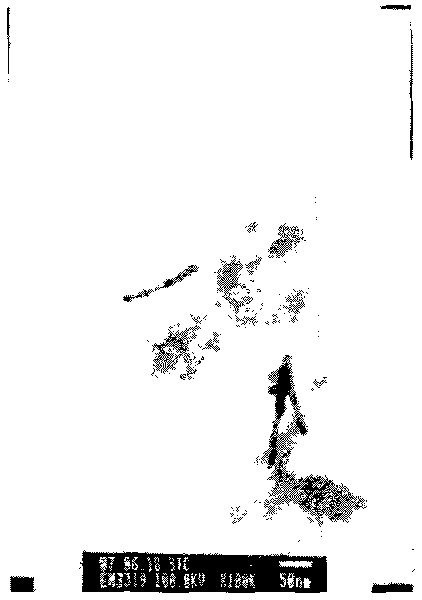

[0018] Specific embodiment two: a specific embodiment is provided below. In this embodiment, AAO templates and gold nanorods are selected; in step 1, the preparation of AAO templates and the growth of gold nanorods are realized in this way: first, the -1 h 2 SO 4 In the solution, keep the temperature at 0-4°C, and use an anodizing voltage of 19V to anodize the aluminum foil for 3 hours once and 2 hours for the second anodization to obtain an AAO template; before the end of the second anodization, use a step-down method , to thin the barrier layer; then use 50Hz alternating current, the voltage is 6.5V, with the aluminum foil with AAO template as the working electrode, in HAuCl 4 4H 2 O+H 3 BO 3 In the solution of AC electrodeposition for 3min, the gold nanorods deposited in the AAO template were obtained; where HAuCl 4 4H 2 The concentration of O is 1g L -1 , H 3 BO 3 The concentration is 30g·L -1 , the pH of the solution=1.5;

[0019] Dissolving the template in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com