Epitaxial strontium barium niobate film possessing transparent conductive lithium nickel oxide bottom electrode and its preparation method

A technology of strontium barium niobate, transparent and conductive, applied in nonlinear optics, instruments, optics, etc., can solve the problems of not having epitaxial growth transmission, etc., and achieve good market prospects, low cost, and good transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

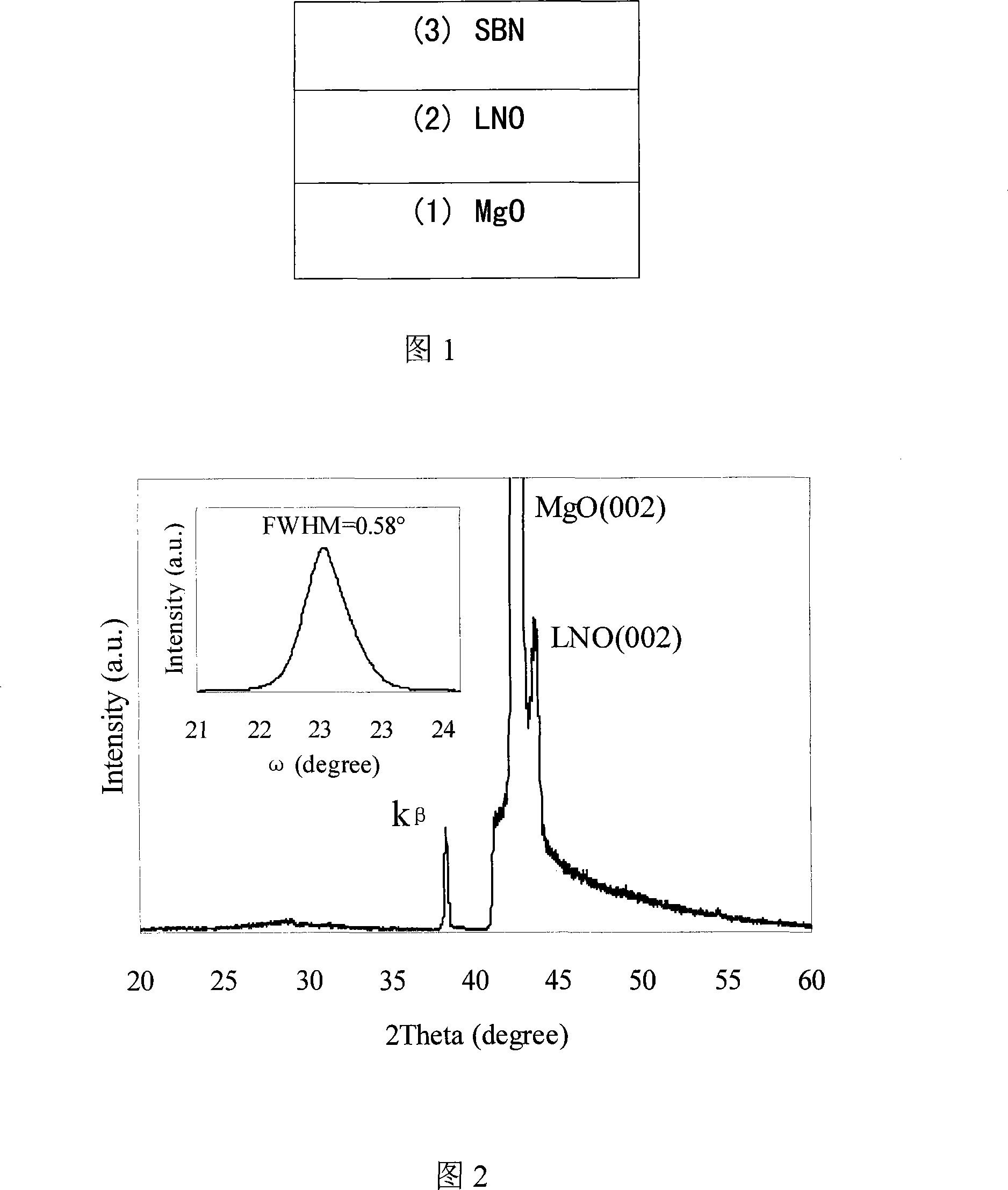

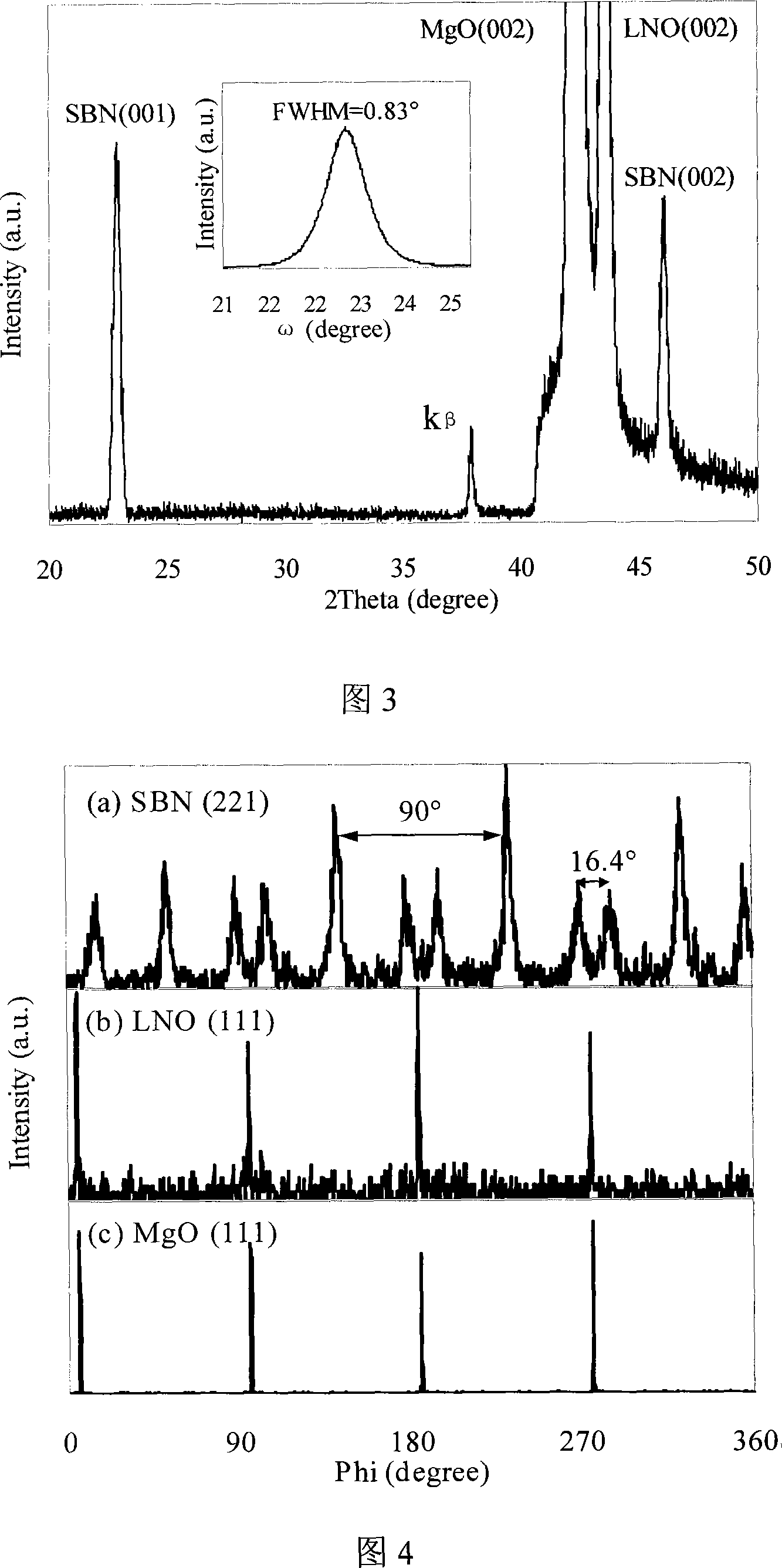

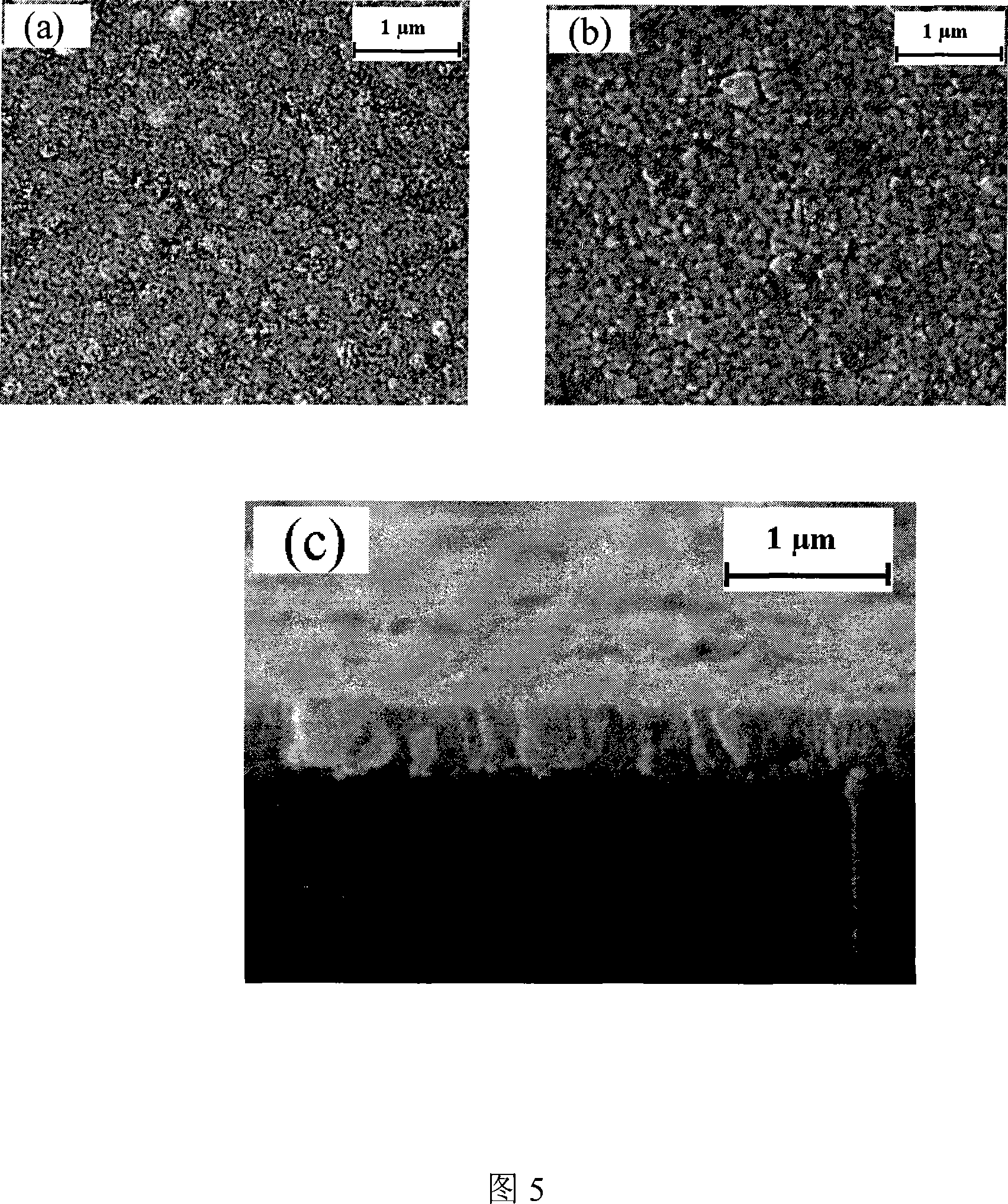

Embodiment 1

[0028] Using lithium carbonate and nickel oxide as raw materials, mix 15% lithium carbonate and 85% nickel oxide according to the mass percentage, grind for 4 hours, press at a pressure of 5MPa, and sinter in air at a sintering temperature of 850 ℃, the heating rate is controlled at 300℃ / h, the holding time is controlled at 2h, and the lithium nickelate target is obtained after cooling down; using strontium carbonate, barium carbonate and niobium oxide as raw materials, strontium carbonate with a mass percentage of 25%, After mixing 30% barium carbonate and 45% niobium oxide, grind for 4 hours, press and shape at a pressure of 6 MPa, and sinter in air, the sintering temperature is 880 °C, the heating rate is controlled at 400 °C / h, and the holding time is controlled at 2.5 h, the strontium barium niobate target was obtained after cooling down; the prepared lithium nickelate target was used to deposit lithium nickelate film on the (001) MgO substrate by pulse laser deposition me...

Embodiment 2

[0030] Using lithium carbonate and nickel oxide as raw materials, mix 10% lithium carbonate and 90% nickel oxide according to the mass percentage, grind for 3 hours, press at a pressure of 2MPa, and sinter in air at a sintering temperature of 800 ℃, the heating rate is controlled at 100℃ / h, the holding time is controlled at 1h, and the lithium nickelate target is obtained after cooling down; using strontium carbonate, barium carbonate and niobium oxide as raw materials, strontium carbonate with a mass percentage of 30%, After mixing 10% barium carbonate and 60% niobium oxide, grind for 5 hours, press and shape at a pressure of 10MPa, and sinter in air, the sintering temperature is 900°C, the heating rate is controlled at 600°C / h, and the holding time is controlled at 3h , after cooling down, the barium strontium niobate target was obtained; the prepared lithium nickelate target was used to deposit lithium nickelate film on the (001) MgO substrate by pulse laser deposition metho...

Embodiment 3

[0032] Using lithium carbonate and nickel oxide as raw materials, mix 17% lithium carbonate and 83% nickel oxide according to the mass percentage, grind for 3 hours, press at a pressure of 5 MPa, and sinter in air at a sintering temperature of 850 ℃, the heating rate control range is 300℃ / h, the holding time is controlled at 1h, and the lithium nickelate target is obtained after cooling down; using strontium carbonate, barium carbonate and niobium oxide as raw materials, strontium carbonate with a mass percentage of 26% , 16% barium carbonate mixed with 58% niobium oxide, ground for 3 hours, press-molded with a pressure of 5MPa, and sintered in air, the sintering temperature was 850°C, the heating rate was controlled at 300°C / h, and the holding time was controlled at After 2 hours, the barium strontium niobate target was obtained after cooling down; using the prepared lithium nickelate target, the lithium nickelate film was deposited on the (001) MgO substrate by using the pulsed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electro-optic coefficient | aaaaa | aaaaa |

| Electro-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com