Innocent treatment method for oil-containing sewage sludge

A harmless treatment, oil sludge technology, applied in water/sludge/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve air pollution, great difficulty in popularization, microbial substances and Problems such as the inability of energy exchange to proceed smoothly, to achieve the effect of promoting maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

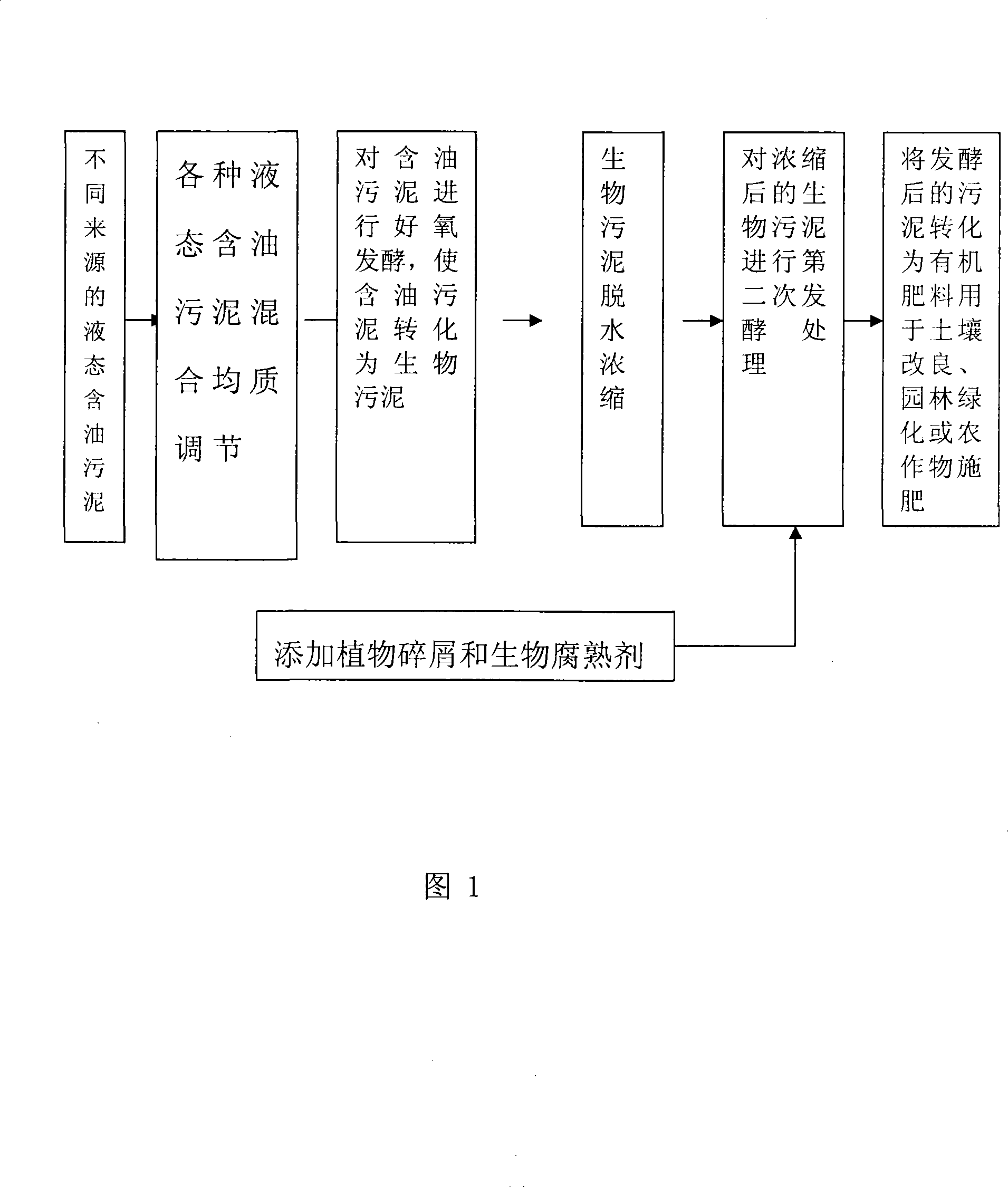

Image

Examples

Embodiment

[0038] This technology was officially implemented in China Petroleum Dagang Petrochemical Company in August 2007. The implementation of this technology was transformed from the original device. The first half of the technology uses the original scum pool to make oily waste The structure and facilities of the sludge adjustment tank have not changed, and there is no new investment; the aerobic microbial oxidation treatment device for oily sludge is only transformed from the original oily sludge dewatering irrigation, and the transformation process only adds some pipelines , connect six dehydration tanks in series, and add aeration devices to five dehydration tanks as aerobic microbial oxidation treatment devices, retain the steam heating facilities of the original oily sludge dehydration tanks, and the remaining one dehydration tank Used as a sludge settling tank, after the oily sludge is oxidized by aerobic microorganisms, it can obtain sufficient settling time and reduce the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com