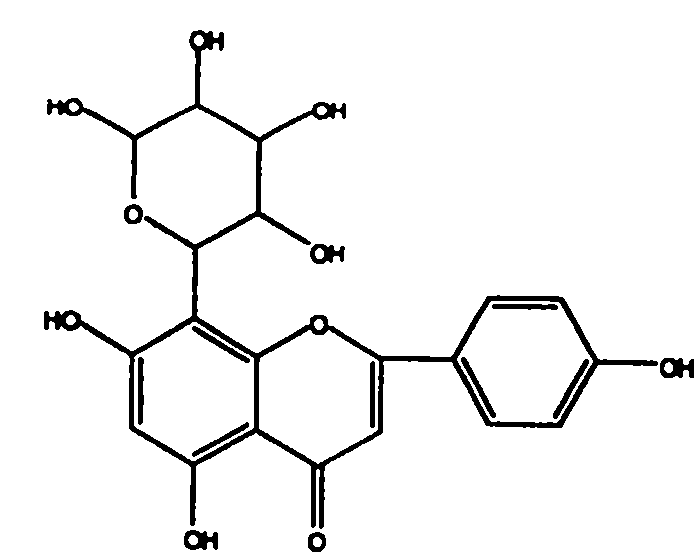

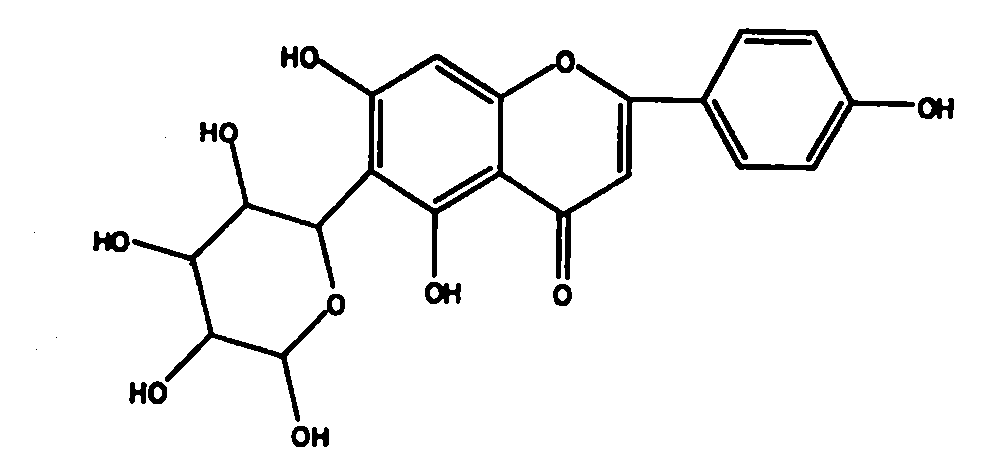

Method for extracting and purifying vitexin and isoviextin from cajanus cajan branches and leaves

A technology of isovitexin and vitexin, applied in the field of separation and purification of functional components, can solve the problems of large amount of organic solvent, backward extraction process, low yield, etc., and achieves simple and easy method, efficient and reasonable utilization, and product high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1000g of pigeon pea dry branches and leaves, add 8 times the volume of 75% ethanol, continuously homogenize and extract 3 times, each 1min, and then ultrasonically assist extraction 3 times under the condition of 35~50°C (add 75% ethanol for the second time The amount is 6 times of the solid mass, the third time is 4 times), each time for 45 minutes, the three extracts are combined, and concentrated under reduced pressure until no obvious liquid flows out.

[0022] Add the concentrated solution into warm water (4.5L) at 60°C, vibrate in an ultrasonic extractor at 30-50KHz for 15-25min, stand still for 10-15min, take the supernatant, and use 0.05MPa negative pressure as the power to extract it with 4L ethyl acetate. Negative pressure cavitation suspension was extracted 3 times, the extract was concentrated, and the obtained solid was warmed and suspended with 8% ethanol to prepare a sample solution with a feed concentration of 10mg / mL, and the maximum sample volume ...

Embodiment 2

[0026] Take by weighing 4.79kg of fresh pigeonpea branches and leaves (dry weight is 1kg), after adding 6 times the volume of 85% ethanol, continuous homogenate extraction 3 times, each time 1.5min, then ultrasonically assisted extraction 3 times under the condition of 35~50 ℃ ( The second and third additions of 85% ethanol are 4 times the solid mass), each time for 45 minutes, the three extracts are combined, concentrated under reduced pressure until no obvious liquid flows out.

[0027]Add the concentrated solution into warm water (4.5L) at 50-60°C, vibrate for 15-25min at 50-60KHz in an ultrasonic extractor, rest for 10-15min, take the supernatant, and use negative pressure as the power to extract it with 4L ethyl acetate. Negative pressure cavitation suspension was extracted 3 times, the extract was concentrated, the obtained solid was suspended with 8% ethanol, and the sample solution with a feed concentration of 12mg / mL was prepared, and the maximum sample volume was 15mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com