Paraffinic hydrocarbon shape selecting isomerization catalyst and method for producing the same

A catalyst and a technology for paraffin hydrocarbons, applied in the field of paraffin hydrocarbon shape-selective isomerization catalyst and preparation thereof, can solve problems such as no reports, and achieve the effects of high viscosity index, high product yield and low pour point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

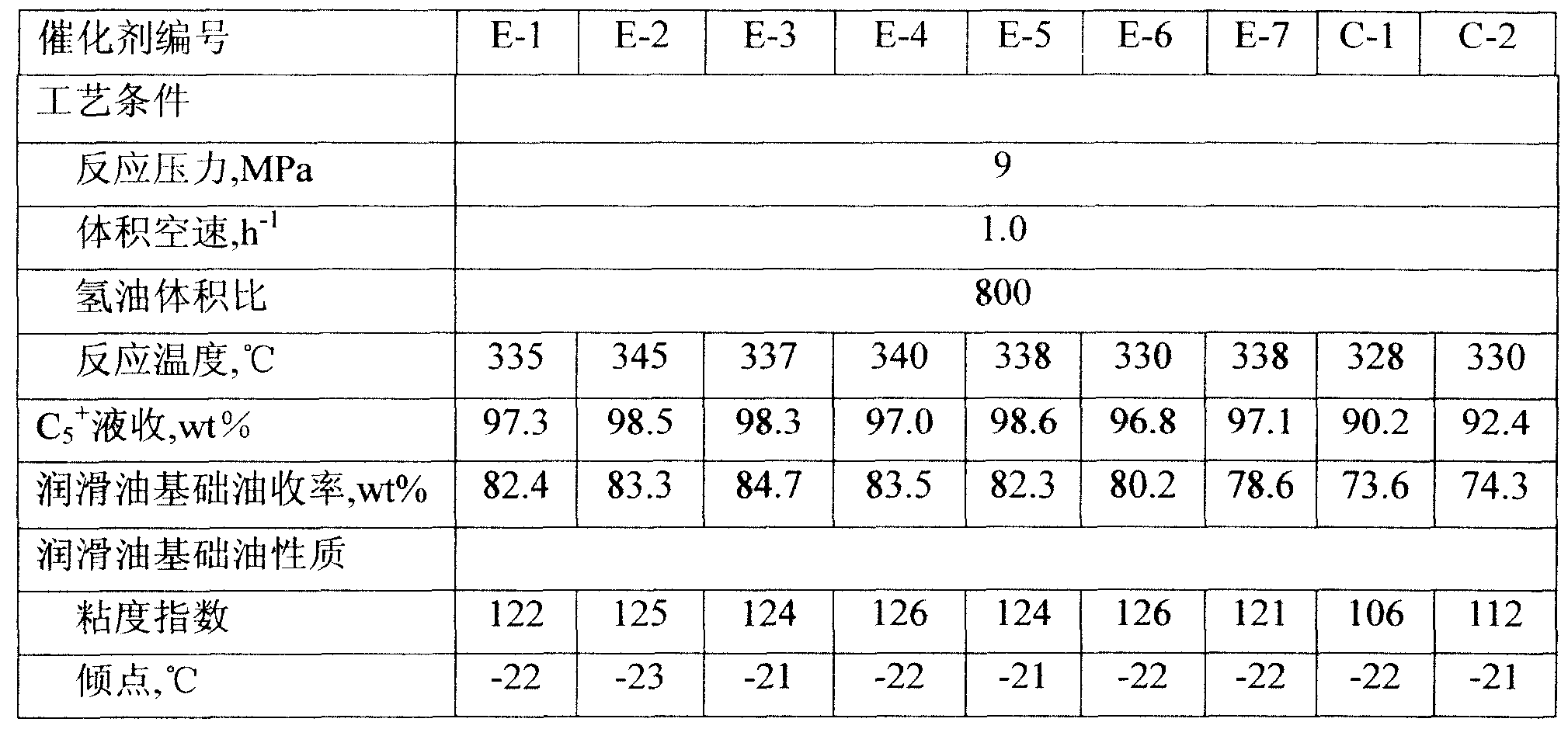

Examples

Embodiment 1

[0036] The preparation method of catalyst (E-1) of the present invention is as follows:

[0037] (1) ZSM-22 used in the present invention is prepared according to the method of Chinese Patent CN1565969A Example 1, and the obtained molecular sieve has a silicon-aluminum molar ratio of 92 and a specific surface area of 223m 2 / g, pore volume 0.21mL / g.

[0038] (2) with La(NO 3 ) 3 ·6H 2 O (produced by Beijing Chemical Plant, analytically pure) and water to prepare 2 o 3 Concentration by weight percentage is 10% aqueous solution, the molecular sieve 4500 grams that step (1) obtains is fully mixed with 5000 grams above-mentioned lanthanum-containing aqueous solution, at 110 ℃ of constant temperature 6 hours, 450 ℃ of constant temperature 6 hours, obtain La 2 o 3 Lanthanum-containing ZSM-22 with a content of 10% by weight.

[0039] (3) the lanthanum-containing molecular sieve (dry basis weight, hereinafter the same) obtained by 1500 gram step (2) and 500 gram (dry basis we...

Embodiment 2

[0042] The preparation method of catalyst (E-2) of the present invention is as follows:

[0043] The preparation method of the catalyst is the same as in Example 1, the difference is that the composition of the catalyst carrier is 20wt% modified ZSM-22 and 80wt% alumina, the content of platinum in the catalyst is 0.74wt%, and the drying and roasting conditions of the catalyst are: 110°C The catalyst was obtained at constant temperature for 4 hours at 420° C. and 6 hours at 420° C., and the catalyst number of the present invention was E-2.

Embodiment 3

[0045] The preparation method of catalyst (E-3) of the present invention is as follows:

[0046] The preparation method of catalyst is the same as embodiment 1, and difference is that used rare earth element compound is (NH 4 ) 2 Ce(NO3) 6 (produced by Beijing Chemical Plant, analytically pure), Ce in the cerium-containing solution used 2 o 3 The content is 2.0wt%, the hydrogenation component is palladium, and the palladium-containing compound used is palladium nitrate, wherein palladium is calculated as metal, and the solution concentration is 3wt%, so as to obtain catalyst E-3 of the present invention, and its composition and physicochemical properties are shown in Table 2 , and the evaluation results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com