Mesopore spherical activated carbon and preparation method thereof

A technology of spherical activated carbon and small balls, which is applied in the field of mesoporous spherical activated carbon, can solve the problems of high cost, many production steps and complicated process of spherical activated carbon, and achieve the effects of high yield, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

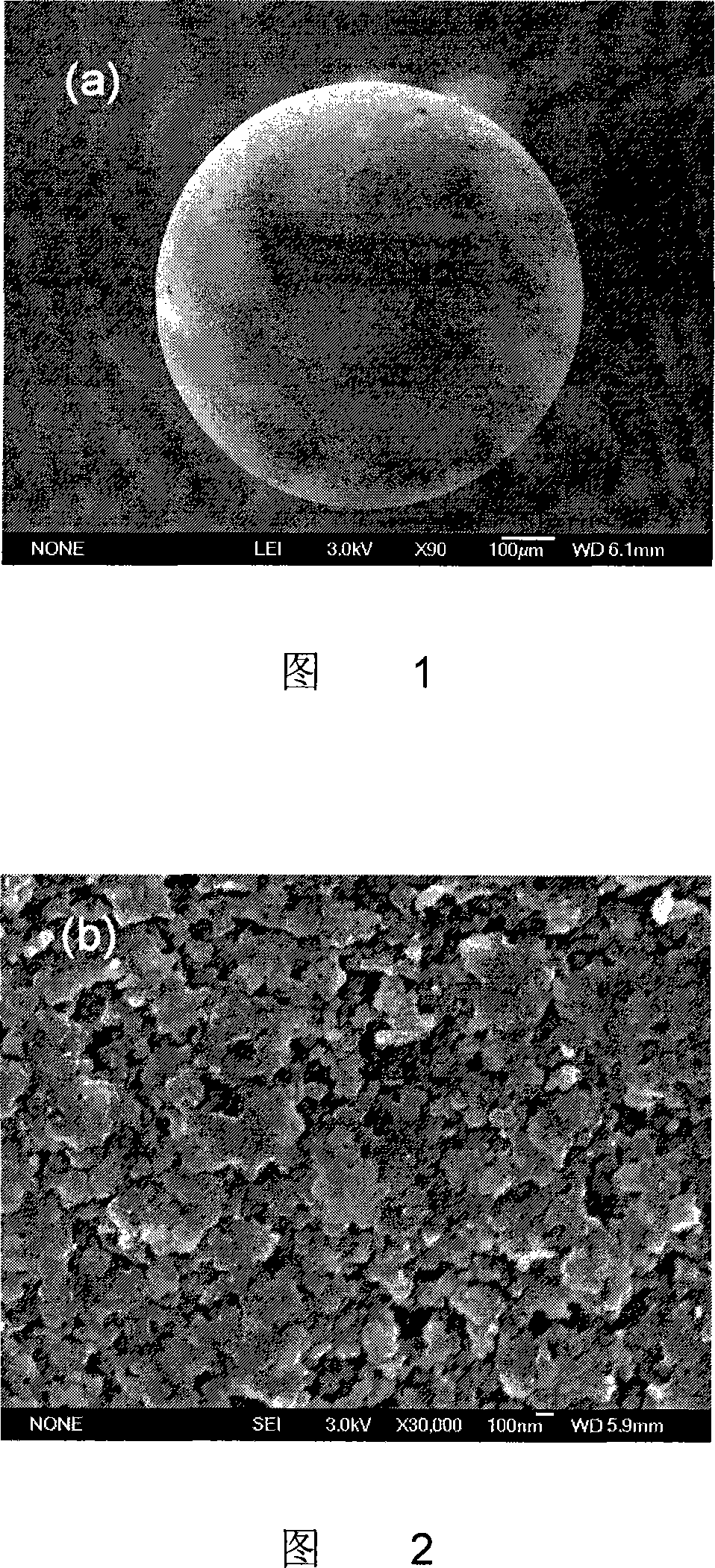

Image

Examples

Embodiment 1

[0020] Styrene-divinylbenzene copolymer pellets with a crosslinking degree of 20% were impregnated with a 10% by weight zinc chloride solution, and stirred at a constant temperature of 30° C. for 15 hours. After filtration, the spherical polymer was dried at 110°C for 8 hours, and then activated at 800°C for 2 hours under the protection of nitrogen. The prepared spherical activated carbon was sequentially used with 0.5mol L -1 dilute hydrochloric acid and distilled water until the effluent is neutral and no chloride ions are detected.

Embodiment 2

[0022] Styrene-divinylbenzene copolymer pellets with a crosslinking degree of 60% were impregnated with a 30% by weight zinc chloride solution, and stirred at a constant temperature of 60° C. for 10 hours. After filtration, the spherical polymer was dried at 110°C for 3 hours, and then activated at 600°C for 2 hours under nitrogen protection. The prepared spherical activated carbon was sequentially washed with 0.1mol L -1 dilute hydrochloric acid and distilled water until the effluent is neutral and no chloride ions are detected.

Embodiment 3

[0024] The polystyrene-divinylbenzene copolymer pellets with a cross-linking degree of 100% were impregnated with a 50% zinc chloride solution, and stirred at a constant temperature of 80° C. for 5 hours. After filtration, the spherical polymer was dried at 110°C for 8 hours, and then activated at 800°C for 5 hours under the protection of nitrogen. The prepared spherical activated carbon was sequentially treated with 0.3mol L -1 dilute hydrochloric acid and distilled water until the effluent is neutral and no chloride ions are detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com