Method for preparing herbicide fenoxaprop-p-ethyl

A technology of fenoxaprop-p-ethyl and herbicides, which is applied in the field of chemical synthesis of fenoxaprop-p-ethyl, can solve problems affecting product quality, increasing raw material costs, and low reaction yield, and achieve high product quality and economical The effect of high raw material and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

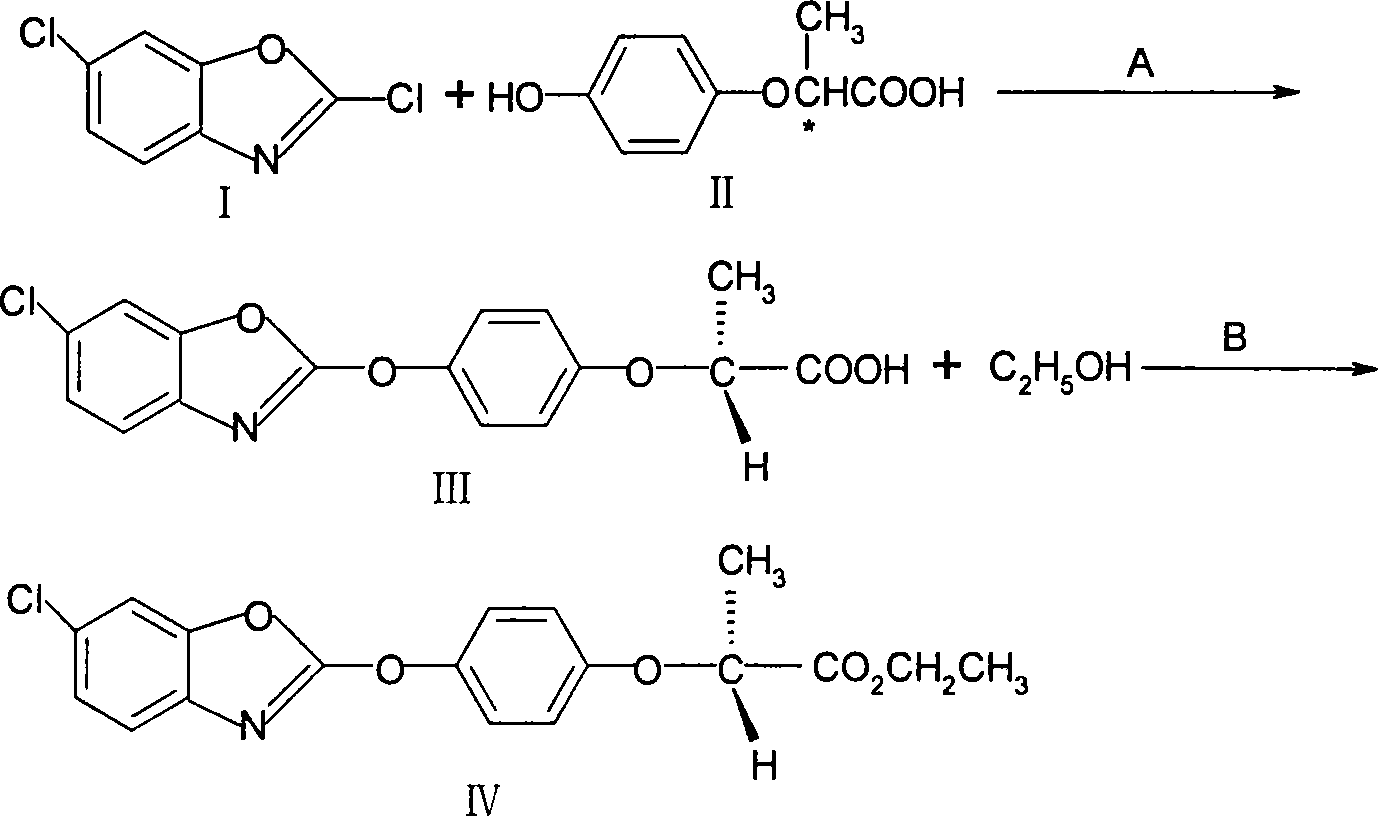

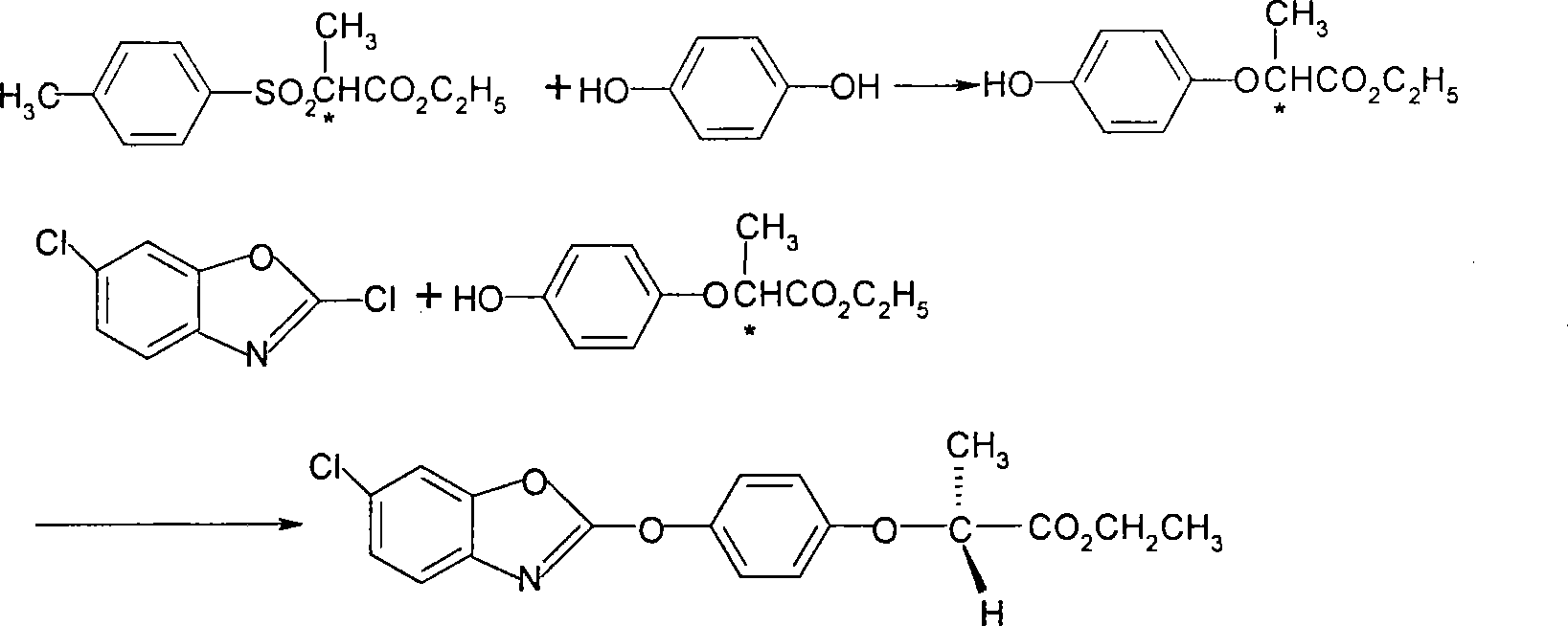

Method used

Image

Examples

Embodiment 1

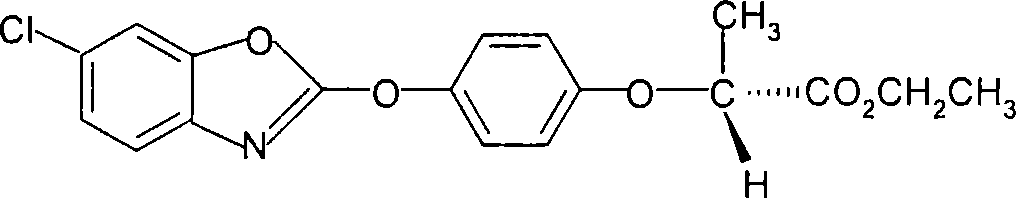

[0025] (1), the preparation of (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionic acid (III)

[0026] Add 150 g of tap water into the reaction flask, cool to 5°C, add 63 g (1.5 mol) of solid sodium hydroxide, add 91 g (0.5 mol) of 2-(4-hydroxyphenoxy)propionic acid (II), stir to form a salt, Then add 1g of phase transfer catalyst, raise the temperature to 50°C, add 197g (0.525mol) of 50% 2,6-dichlorobenzoxazole (I) dropwise, then keep the temperature for 4 hours, then heat up to 80-90°C, keep the temperature After 1 hour, the toluene layer was separated and the pH of the aqueous layer was adjusted to 3-4 with hydrochloric acid. A gray powdery solid was precipitated and dried to obtain 172 g of crude product, with a yield of 95%.

[0027] (2), preparation of (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionate ethyl ester (IV)

[0028] Add (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionic acid (III) 172.5g (0.5mol) in the reaction flask, without 415...

Embodiment 2

[0030] (1), the preparation of (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionic acid (III)

[0031] Add 150 g of tap water in the reaction flask, cool to 5° C., add 84 g (2 mol) of solid sodium hydroxide, add 91 g (0.5 mol) of 2-(4-hydroxyphenoxy) propionic acid (II), stir to form a salt, and then Add 1 g of phase transfer catalyst, raise the temperature to 50° C., add 206 g (0.55 mol) of 50% 2,6-dichlorobenzoxazole (I) dropwise, then keep the temperature for 4 hours, then raise the temperature to 70-80° C., and keep the temperature for 1 After 1 hour, the toluene layer was separated, and the pH of the water layer was adjusted to 3-4 with hydrochloric acid. A gray powdery solid was precipitated, and the crude product was dried to obtain 173.4 g, with a yield of 96%.

[0032] (2), preparation of (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionate ethyl ester (IV)

[0033] Add (R)-2-[4-(6-chloro-1,3-benzoxazol-2-yloxy)phenoxy]propionic acid (III) 172.5g (0.5...

Embodiment 3

[0035] Take by weighing 8.76 grams of fenoxaprop-methyl, 2.9 grams of oxapropen, and 12 grams of 20 grams of nonylphenol polyoxyethylene ether as a solvent, 4 grams of ethylene glycol, 0.2 grams of xanthan gum, and 0.15 grams of benzoic acid, and hydrolyze to 100 g to obtain the product. The obtained product is measured with a particle size distribution tester to have an average particle diameter of 1.05 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com