Technology for preparing nano-carbon tube-silica dioxide gel glass

A technology of carbon nanotubes and gel glass, applied in the field of material chemistry, can solve problems affecting the performance of carbon nanotubes, easy to agglomerate, and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] (1) Carboxylation of carbon nanotubes: reflux 1 g of carbon nanotubes with 80 ml of concentrated nitric acid at 120° C. for 12 hours, wash and filter with distilled water. Because the solvent is concentrated nitric acid, a polytetrafluoroethylene microporous membrane that can withstand strong acids is used for filtration. Wash and filter several times until the pH of the filtrate is about 7. The solid was dried under vacuum at 40°C for 24 hours, and ground into powder for later use. After the above treatment, CNTs-COOH was obtained.

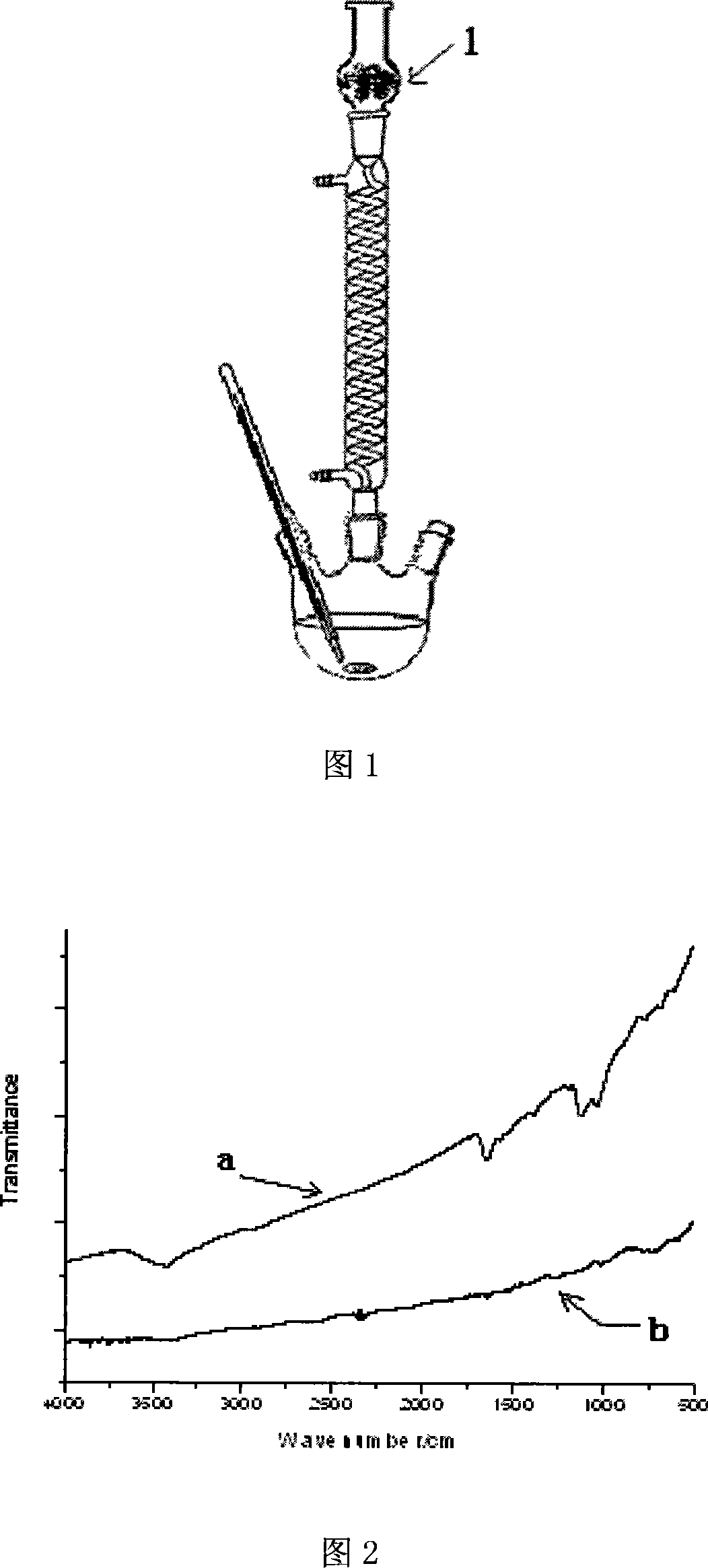

[0023] (2) Acyl chlorination of carbon nanotubes: combine CNTs-COOH obtained in step 1 with 30ml thionyl chloride (SOCl 2 ) was refluxed at 80° C. for 24 hours. Anhydrous calcium chloride (CaCl 2 ) placed at the air interface of the condenser tube to prevent the intrusion of moisture, as shown in Figure 1. The excess SOCl was removed by distillation under reduced pressure 2 It is directly removed from the system to prevent the CNTs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com