Y2O3-TiO2 series microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic, Y2O325 technology, used in ceramics, inorganic insulators, etc., can solve the problems of complex phase composition and large dielectric loss, and achieve the effects of excellent dielectric properties, improved dielectric constant, and reduced relative excess.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

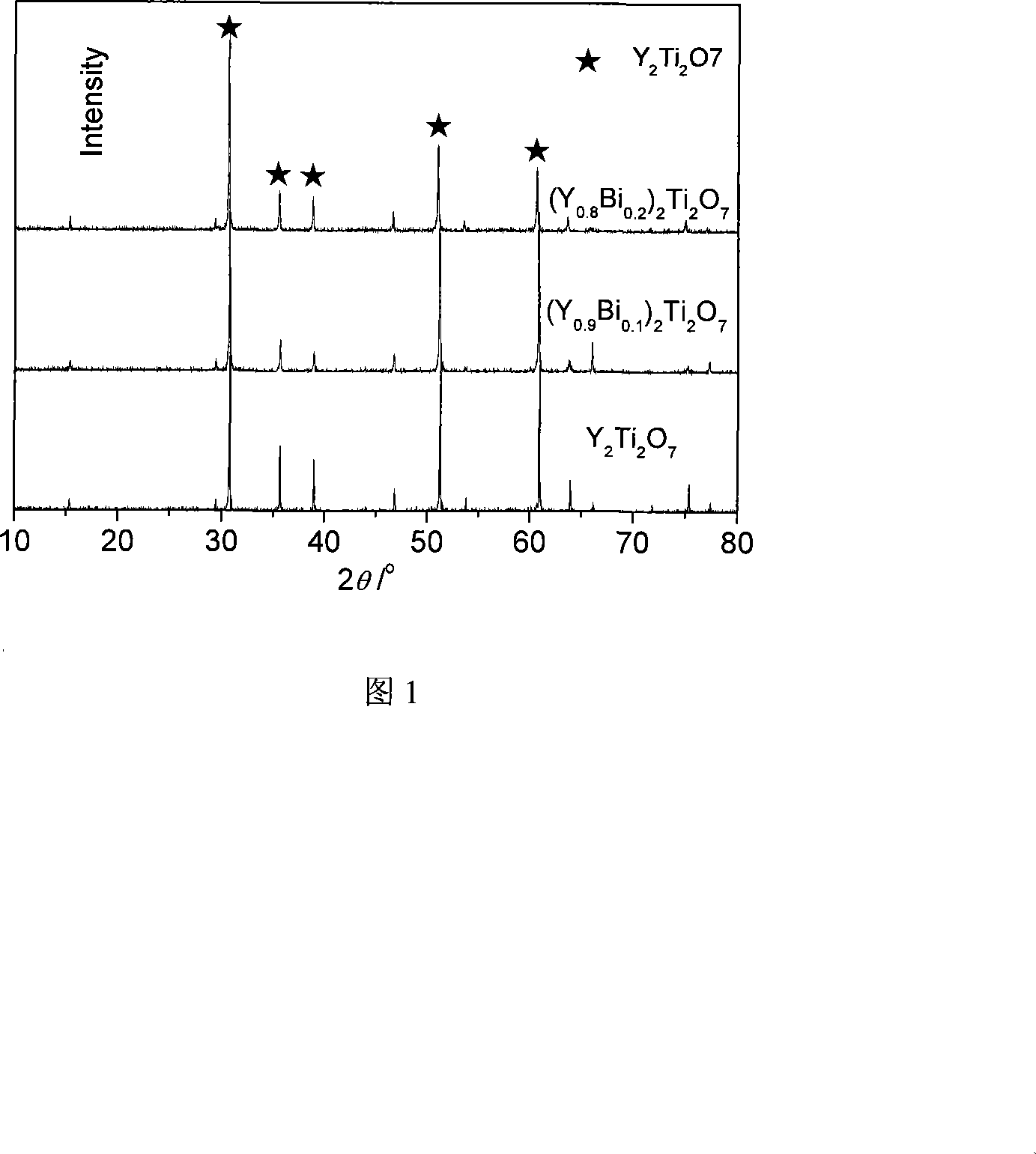

Image

Examples

Embodiment 1

[0031] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0032] 1. Calculate the percentage by weight of the raw material according to the molar percentage (mol%) of the composition of the selected raw material, and then weigh the raw material.

[0033] ②Put the weighed sample in a ball mill jar and perform wet ball milling for 16 hours.

[0034] ③After the raw materials are dried, pre-fire at 1050°C in the atmosphere for 5 hours, the heating rate is 3.5°C / min, and then cool down with the furnace.

[0035] ④ Wet ball mill the pre-burned material on a planetary mill for 6 hours (300 rpm).

[0036] ⑤ Add PVA binder with a concentration of 7wt% according to the ratio of 7wt%, grind it in an agate mortar for about 1 hour to granulate, and pass through an 80-mesh sieve.

[0037] 6. Compress the powder mixed with 7wt% PVA into thin discs with a thickness of about 3 mm and a diameter of 13 mm with a powder tablet press, and the press...

Embodiment 2

[0042] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0043] 1. Calculate the percentage by weight of the raw material according to the molar percentage (mol%) of the composition of the selected raw material, and then weigh the raw material.

[0044] ②Put the weighed sample in a ball mill jar and perform wet ball milling for 18 hours.

[0045] ③ After the raw materials are dried, pre-fire at 1100°C for 3 hours in the atmosphere, with a heating rate of 3.5°C / min, and then cool down with the furnace.

[0046] ④ Wet ball mill the pre-burned material on a planetary mill for another 6 hours (300 rpm).

[0047] ⑤Add PVA binder with a concentration of 7wt% in the proportion of 8wt%, grind it in an agate mortar for about 1 hour to granulate, and pass through an 80-mesh sieve.

[0048] 6. Compress the powder mixed with 8wt% PVA into thin discs with a thickness of about 3 mm and a diameter of 13 mm with a powder tablet press, and the...

Embodiment 3

[0053] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0054] 1. Calculate the percentage by weight of the raw material according to the molar percentage (mol%) of the composition of the selected raw material, and then weigh the raw material.

[0055] ②Put the weighed sample in a ball mill jar and perform wet ball milling for 24 hours.

[0056] ③ After the raw materials are dried, pre-fire at 1200°C for 2 hours in the atmosphere, with a heating rate of 3.5°C / min, and then cool down with the furnace.

[0057] ④ Wet ball mill the pre-burned material on a planetary mill for 6 hours (300 rpm).

[0058] ⑤Add PVA binder with a concentration of 7wt% in the proportion of 7wt%, grind it in an agate mortar for about 3 hours to granulate, and pass through an 80-mesh sieve.

[0059] 6. Compress the powder mixed with 7wt% PYA into thin discs with a thickness of about 3 mm and a diameter of 13 mm with a powder tablet press, and the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com