Al2O3dispersion strengthening copper alloy and method for producing the same

A technology for dispersion strengthening copper and alloys, applied in the field of metal materials, can solve the problems of complex process, difficult oxidation, long oxidation time, etc., and achieve the effects of simple process, short time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

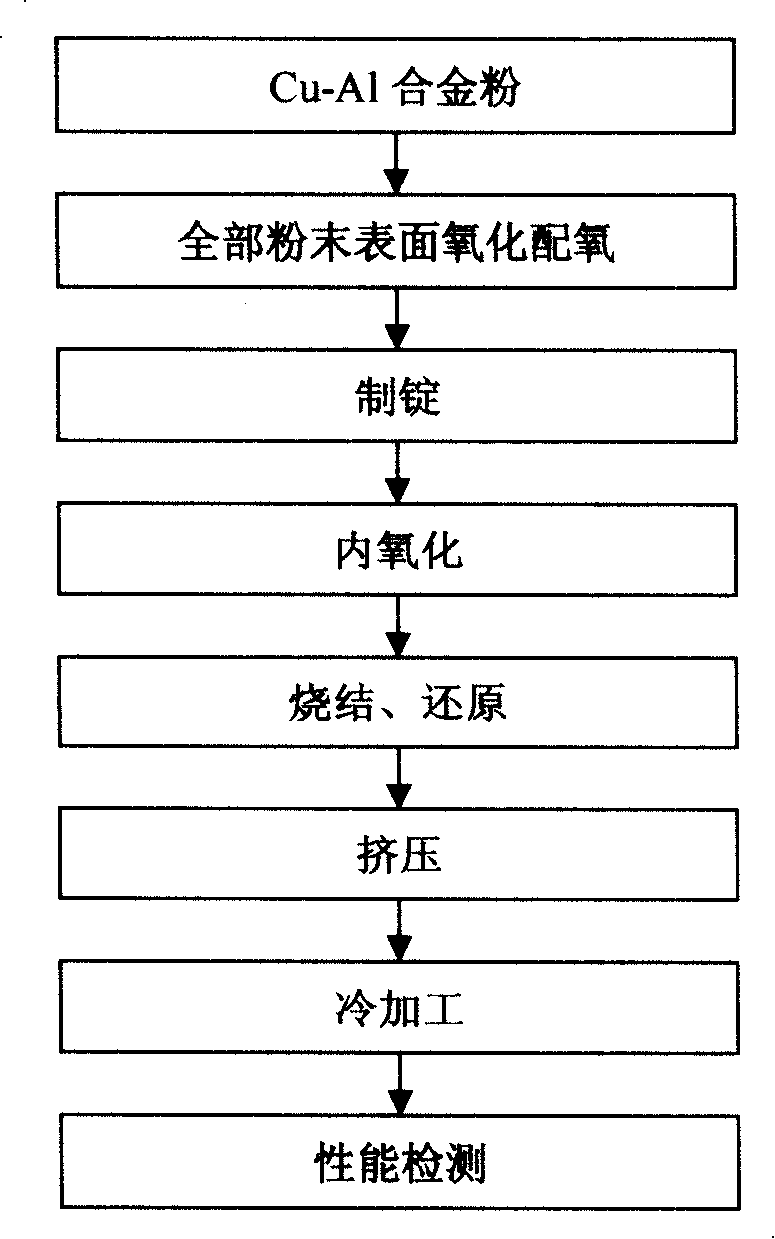

Method used

Image

Examples

specific Embodiment approach 2

[0030] Take the production of alloy for high-voltage isolation switch conductive rod as an example. The raw material is copper-aluminum alloy powder with aluminum content of 0.15wt% and the rest of copper;

[0031] 1. Oxidation and oxygen distribution on the surface of all powders: oxidize the copper-aluminum alloy powder in an oxidizing atmosphere for 20 hours; perform surface oxidation, and the atomic ratio of the oxygen distribution to the aluminum content in the alloy powder is between 3:2 and 6:2;

[0032] 2. Ingot making: the fully oxidized powder is put into an isostatic pressing rubber sleeve, and then it is pressurized to 200N / mm in the cylinder of the cold isostatic pressing machine 2 forming;

[0033] 3. Internal oxidation: treat the isostatically pressed ingot at 880°C under nitrogen protection for 2 hours;

[0034] 4. Sintering and reduction: reduction in a hydrogen atmosphere at 900°C for 5 hours, and then sintering in a hydrogen atmosphere at 980°C for 2 hours;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com