Battery pack

A technology for battery packs and battery components, which is applied in the direction of batteries, battery pack components, secondary batteries, etc., and can solve problems such as small sealing width, shortened battery life, and poor battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

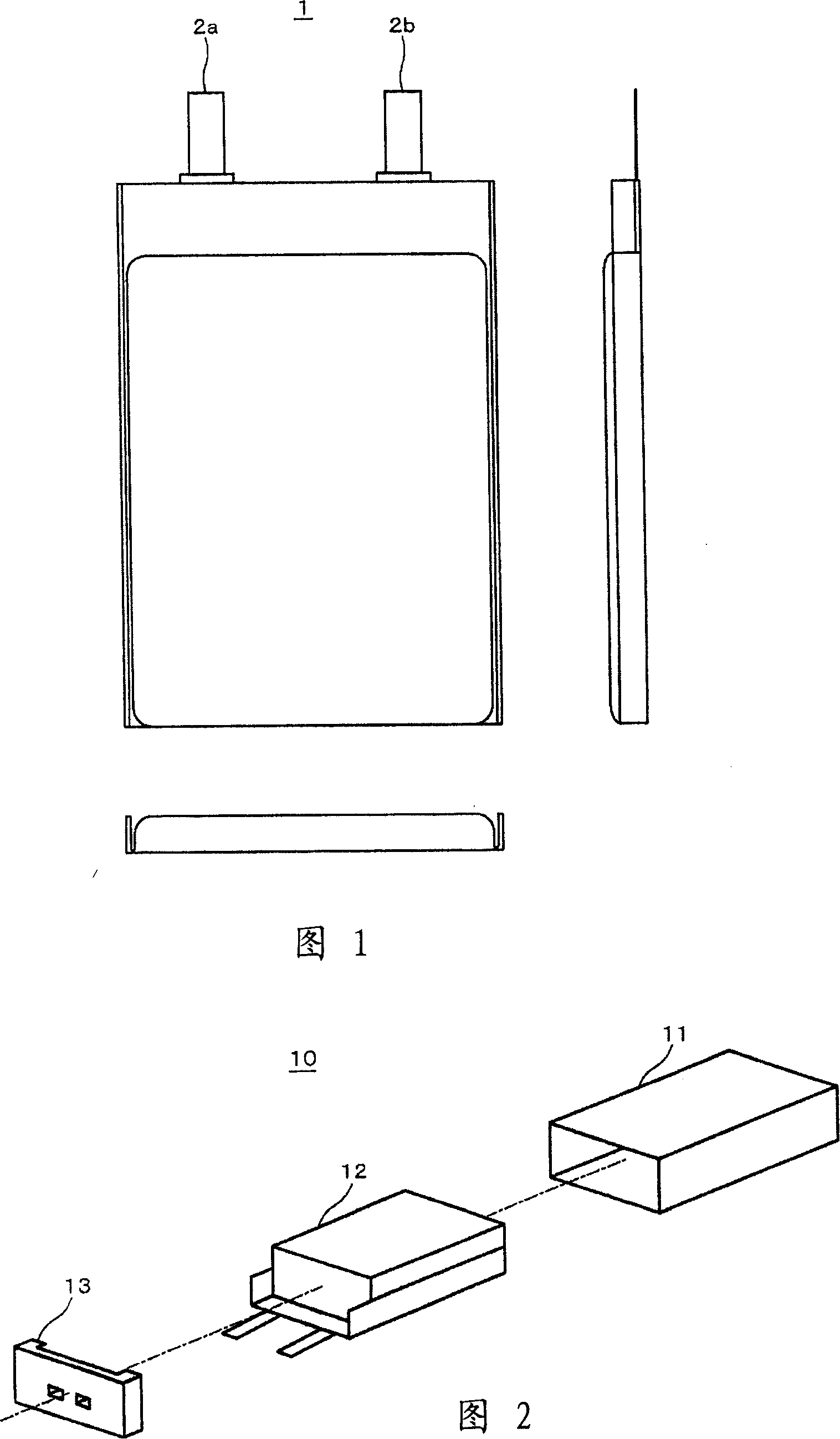

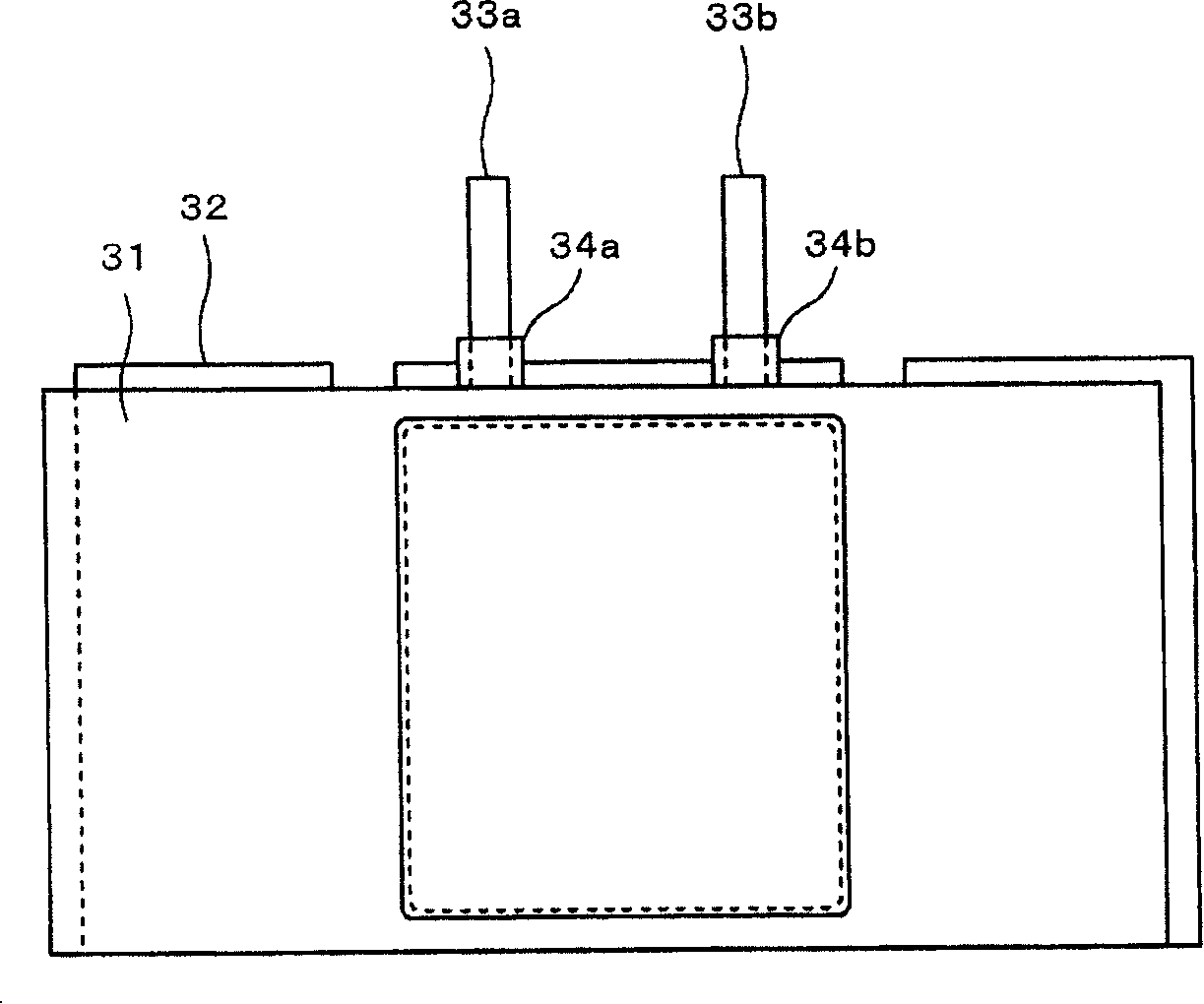

[0054] In the first embodiment, a battery pack having a structure using a rigid laminate film having a four-layer structure as a rigid covering material is described.

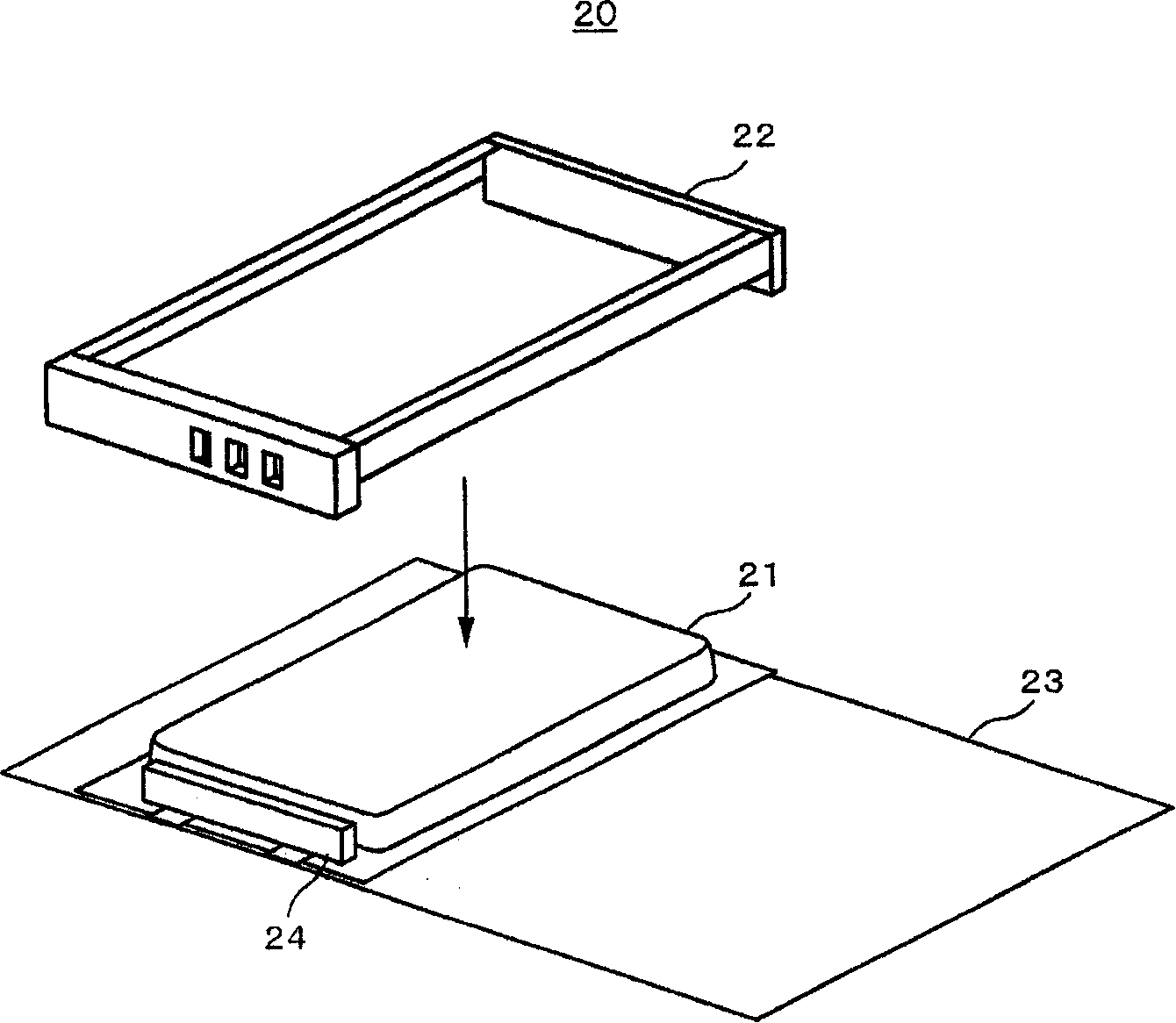

[0055] Figure 6 An appearance of a battery pack for a lithium ion polymer secondary battery according to an embodiment of the present invention is shown. The battery pack 40 includes an electrical generator device contained in a rigid laminate film 41 as a covering material, a top cover 42 and a bottom cover 43, and optionally a product label 46, wherein the top cover and the bottom cover are resin molded covers and assembled into the openings at the ends of the cover material.

[0056] In this description, a unit with a battery element covered by a flexible laminate film is referred to as a "generator device", and a unit with a generator device covered by a rigid laminate film 41 is referred to as a "battery cell", with Such as Figure 6 The shown unit having the structure of the battery cell to which the ...

no. 2 approach

[0132] In a second embodiment, a battery pack using a rigid laminate film having a three-layer structure as a rigid covering material is described.

[0133] The packaging structure of the battery pack according to the second embodiment and Figure 6 The structure is similar to that of the first embodiment shown in 7. In addition, the battery element and the power generator device are similar to those in the first embodiment, so descriptions thereof are omitted.

[0134] Preparation of battery cells

[0135] The generator device 50 consists of Figure 22 The illustrated rigid laminate film 80 having a three-layer structure is overlaid to form a battery cell. First, the structure of the rigid laminate film 80 will be described.

[0136] Such as Figure 22 As shown, the rigid laminated film 80 in the second embodiment is composed of a multilayer film having moisture resistance and insulating properties, and the multilayer film includes a metal foil indicated by reference num...

Embodiment

[0150] Hereinafter, the present invention will be described in detail with reference to the following examples, but these examples are not intended to limit the scope of the present invention.

[0151] (I) thermal adhesion test

[0152] Using a rigid laminate film having a three-layer or four-layer structure prepared using different resin materials in the sealant layer and the thermal adhesive layer, the measurements of the following items (a) to (c) were individually performed.

[0153] Rigid laminate films in Examples 1-1 to 1-34 and Comparative Examples 1-1 and 1-2 were prepared separately, wherein Al was used for the metal layer and Ny was used for the outer packaging layer, Table 1 below The materials shown in were used for the sealant layer and thermal bond layer. The outer wrapping layer and the sealant layer are separately formed by applying a film material to the metal foil via an adhesive layer, and the thermal adhesive layer is formed by diluting a hot-melt resin w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com