Rare earth Fe basis suction wave material and method for making the same

A wave-absorbing material and rare earth technology, applied in the field of wave-absorbing materials, can solve problems such as difficult to meet high performance, lower soft magnetic properties, unfavorable wave-absorbing performance, etc., and achieve the effect of low oxidation resistance, low cost, and good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

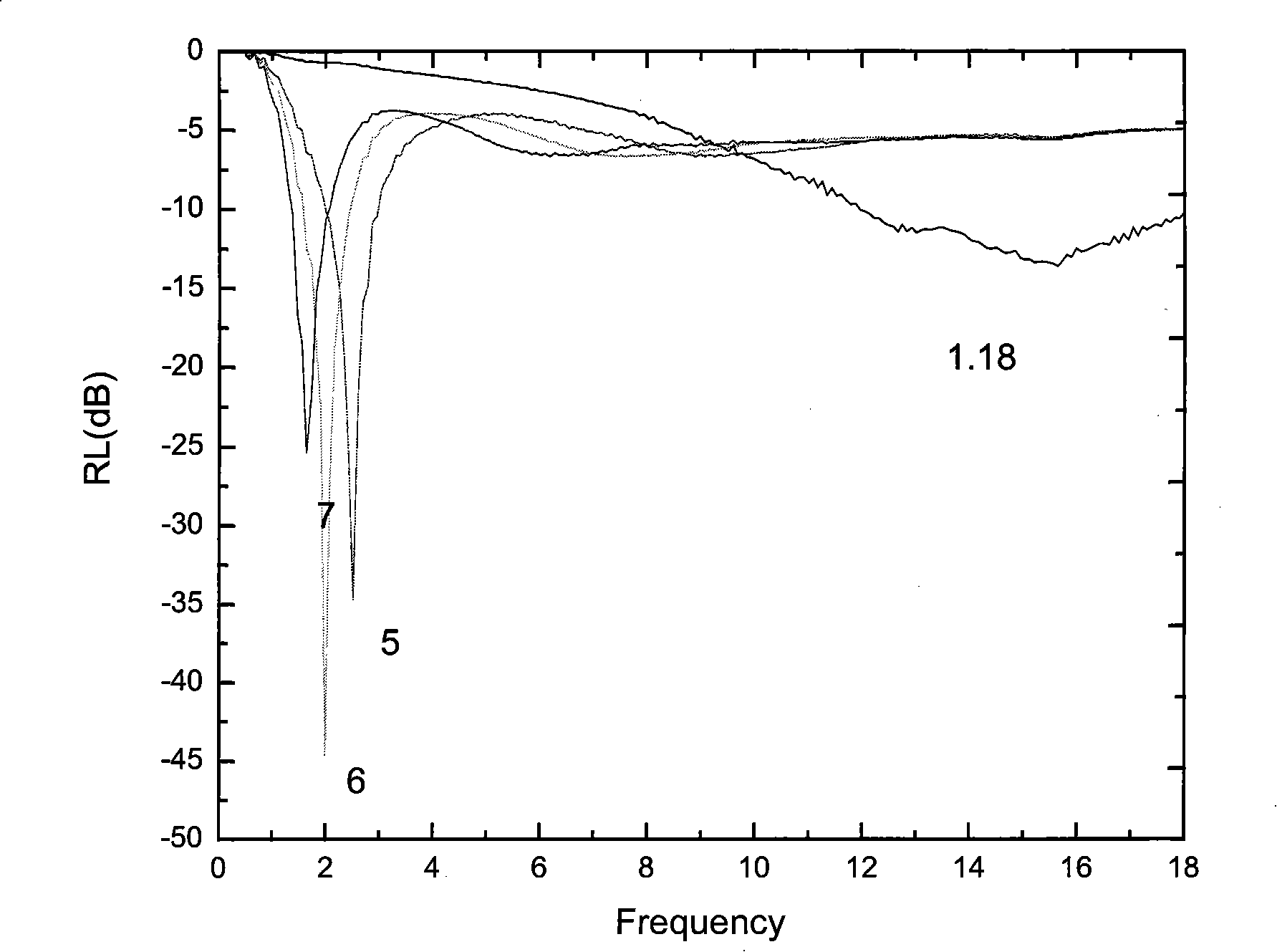

[0019] In this embodiment, 25% samarium and 75% pure iron are smelted into ingots under the protection of argon, and the hydrogen explosion (HD) method is used to make it broken and decomposed into nanocrystalline SmHx / α-Fe composite structure , and then nitrided into nanocrystalline samarium nitride / α-Fe dual-phase powder, the alloy powder is mixed with paraffin at a ratio of 1:5, and then pressed into rings (D=7mm, d=3.01mm, h=3mm) and rectangular (L*W=7.2*3.6mm, thickness 0.9mm), the reflection coefficient of the sample is measured by Agilent E8363 electromagnetic wave vector network analyzer. Related parameter μ r , ε r Determined by the scattering coefficient and the thickness of the sample, ε" reaches 10 at a frequency of 5 GHz, μ' reaches a maximum of 3.21, and μ" reaches a maximum of 0.95. Its absorption peak reaches -45 decibels (dB), and the bandwidth of the absorption rate less than -10dB is 5GHz, the absorbing curve is as figure 1 shown.

Embodiment 2

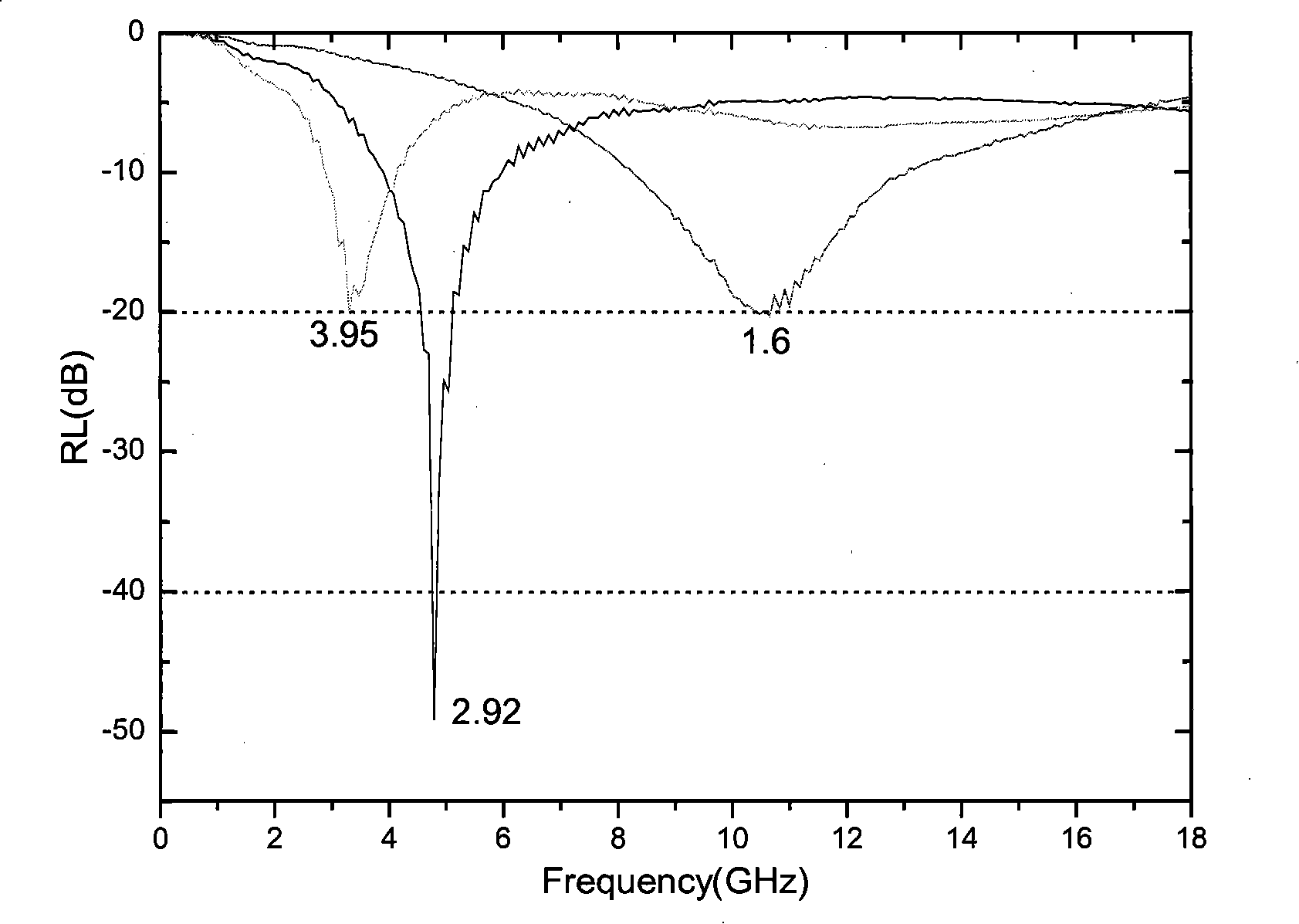

[0021] In this embodiment, 40% samarium and 60% pure iron are smelted into ingots under the protection of argon, and are broken and decomposed into nanocrystalline SmHx / α-Fe composite structure by hydrogen explosion (HD). , and then oxidized into nanocrystalline samarium oxide / α-Fe dual-phase powder, the alloy powder was mixed with paraffin at a ratio of 1:5, and then pressed into rings (D=7mm, d=3.01mm, h=3mm) and Rectangle (L*W=7.2*3.6mm, thickness 0.9mm), the reflection coefficient of the sample is measured by Agilent E8363 electromagnetic wave vector network analyzer. Related parameter μ r , ε r Determined by the scattering coefficient and the thickness of the sample, ε″ reaches 3.15 at a frequency of 7.6GHZ, the maximum value of μ′ is 2.9, and the maximum value of μ″ is 0.86. The absorption peak reaches -50 decibels (dB), and the absorption rate is less than the bandwidth of -10dB is 5.1GHz, the absorbing curve is as figure 2 shown.

Embodiment 3

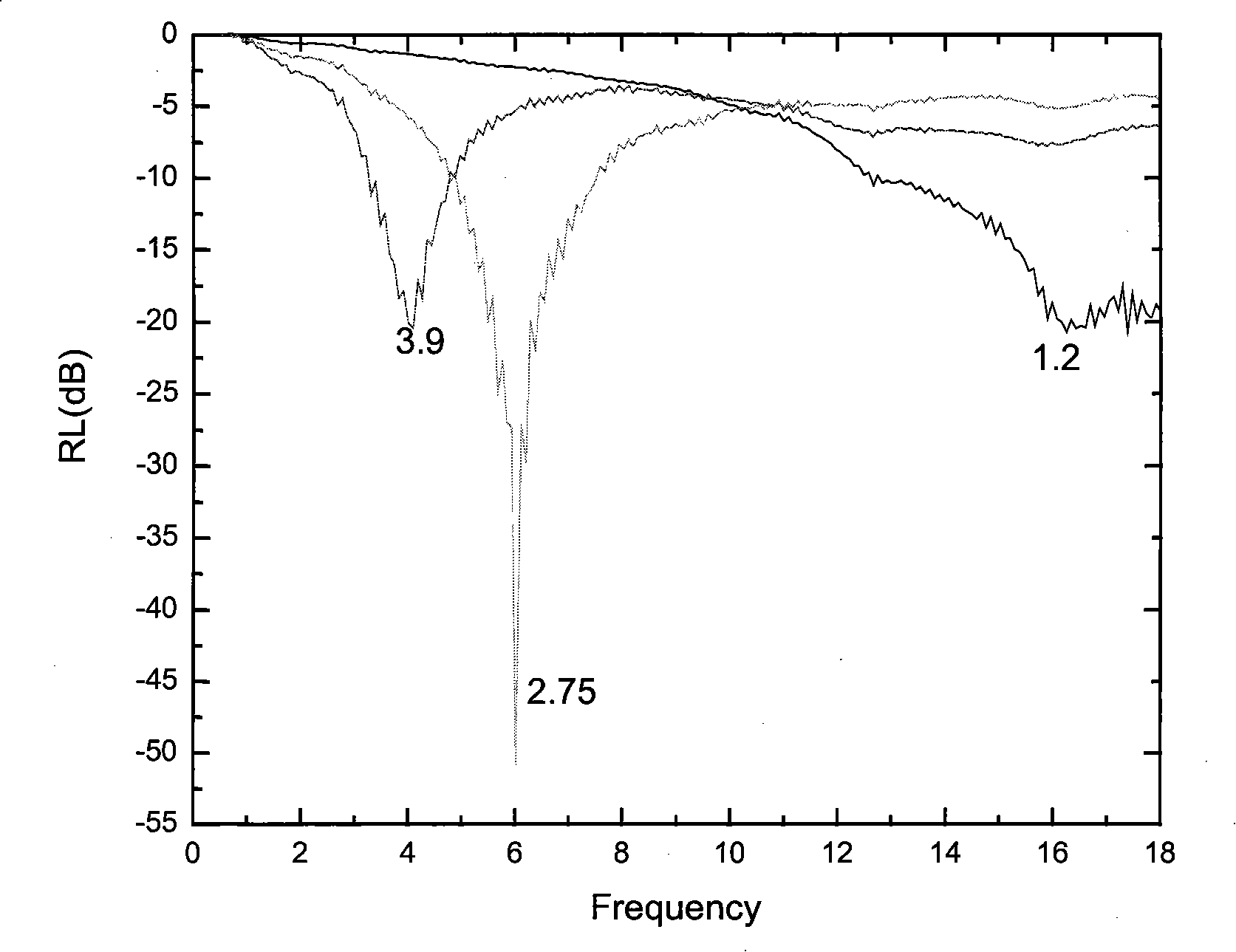

[0023] In this embodiment, 12% neodymium, 86% pure iron and trace amounts of tungsten and chromium elements are used in this embodiment, melted into ingots under the protection of argon, and are broken and decomposed into nanometers by hydrogen explosion (HD). crystalline NdHx / α-Fe composite structure, then crushed into powder, and then nitrided into nanocrystalline samarium nitride / α-Fe dual-phase composite powder, the alloy powder is mixed with paraffin at a ratio of 1:5, and then pressed into rings (D=7mm, d=3.01mm, h=3mm) and rectangular (L*W=7.2*3.6mm, thickness 0.9mm) reflection coefficients of samples were measured with Agilent E8363 electromagnetic wave vector network analyzer. Related parameter μ r , ε r Determined by the scattering coefficient and the thickness of the sample, ε″ reaches 4.0 at a frequency of 8GHZ, μ′ reaches a maximum of 4, and μ″ reaches a maximum of 1.2. The absorption peak reaches -50 decibels (dB), and the bandwidth of the absorption rate less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com