High-conductivity epoxy moulding material having heat conducting path and manufacturing method thereof

A technology of epoxy molding compound and heat conduction path, which is applied in the field of microelectronic packaging, can solve the problems of introduction and reporting of epoxy molding materials and preparation methods, and achieve good application prospects, good processability, performance and The effect of cost uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

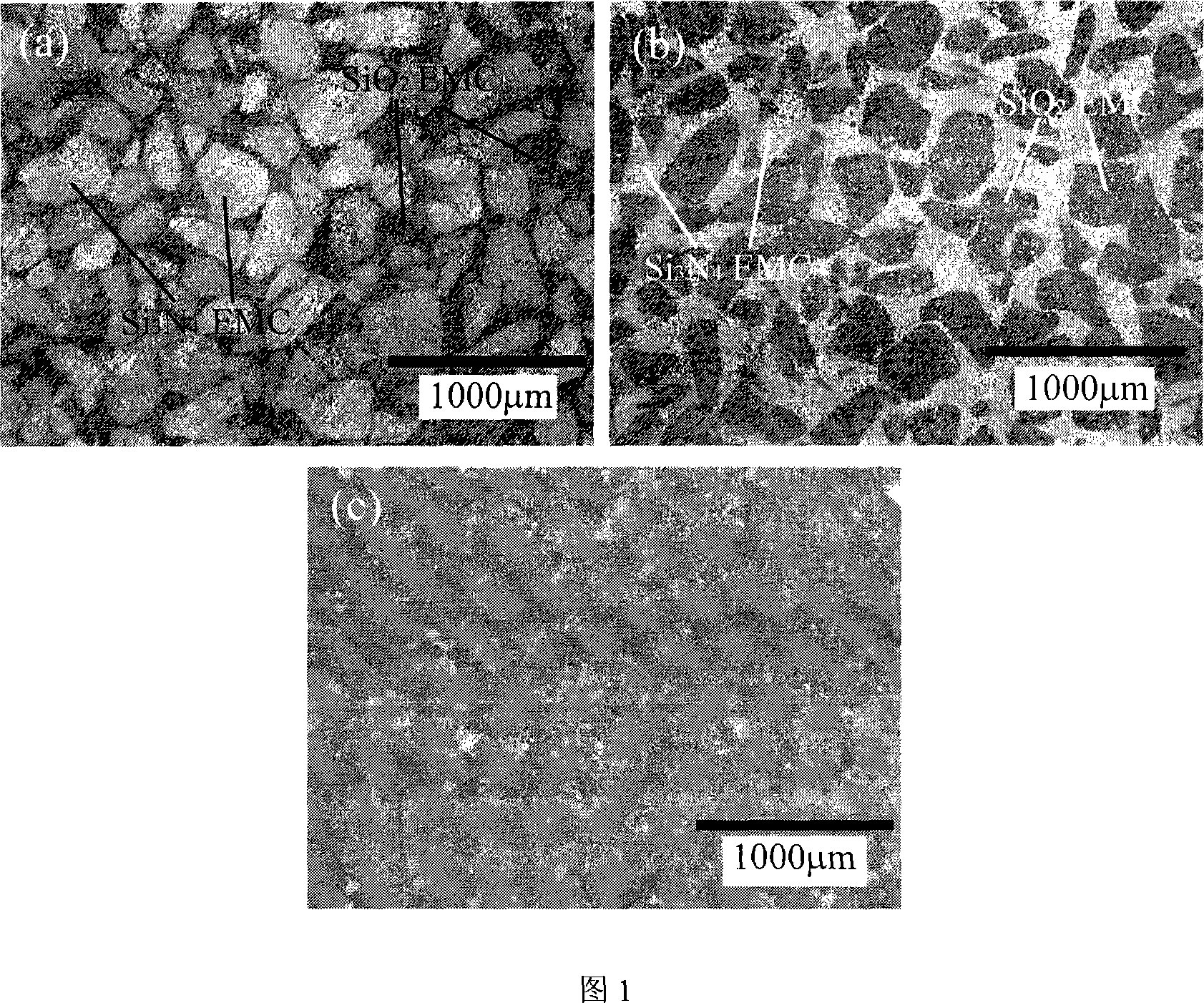

[0031] (2) Example 1 of the present invention: low thermal conductivity molding particles are the skeleton, and high thermal conductivity molding powder is used as the channel

[0032] Step 1: Exactly the same as Step 1 of Comparative Example 1.

[0033] Step 2: Exactly the same as Step 3 of Comparative Example 1.

[0034]Step 3: Use the molding powder prepared in step 2 to make low thermal conductivity molding compound granules.

[0035] Step 4: Mix 40 parts of silicon dioxide epoxy molding compound particles and 60 parts of silicon nitride epoxy molding powder by ball milling for 2 hours, put them in a vacuum drying oven for degassing for 1 hour after mixing, and then put the mixture Hot press at 175°C and 100MPa for 5 minutes, put it into a vacuum drying oven after cooling, and post-cure at 175°C for 4 hours. After cooling, a silicon nitride epoxy molding compound sample filled with silica epoxy molding compound particles was obtained. The product properties are shown in ...

example 2

[0043] Step 1: Exactly the same as Step 1 of Comparative Example 1.

[0044] Step 2: Exactly the same as Step 3 of Comparative Example 1.

[0045] Step 3: Use the molding powder prepared in step 2 to make low thermal conductivity molding particles.

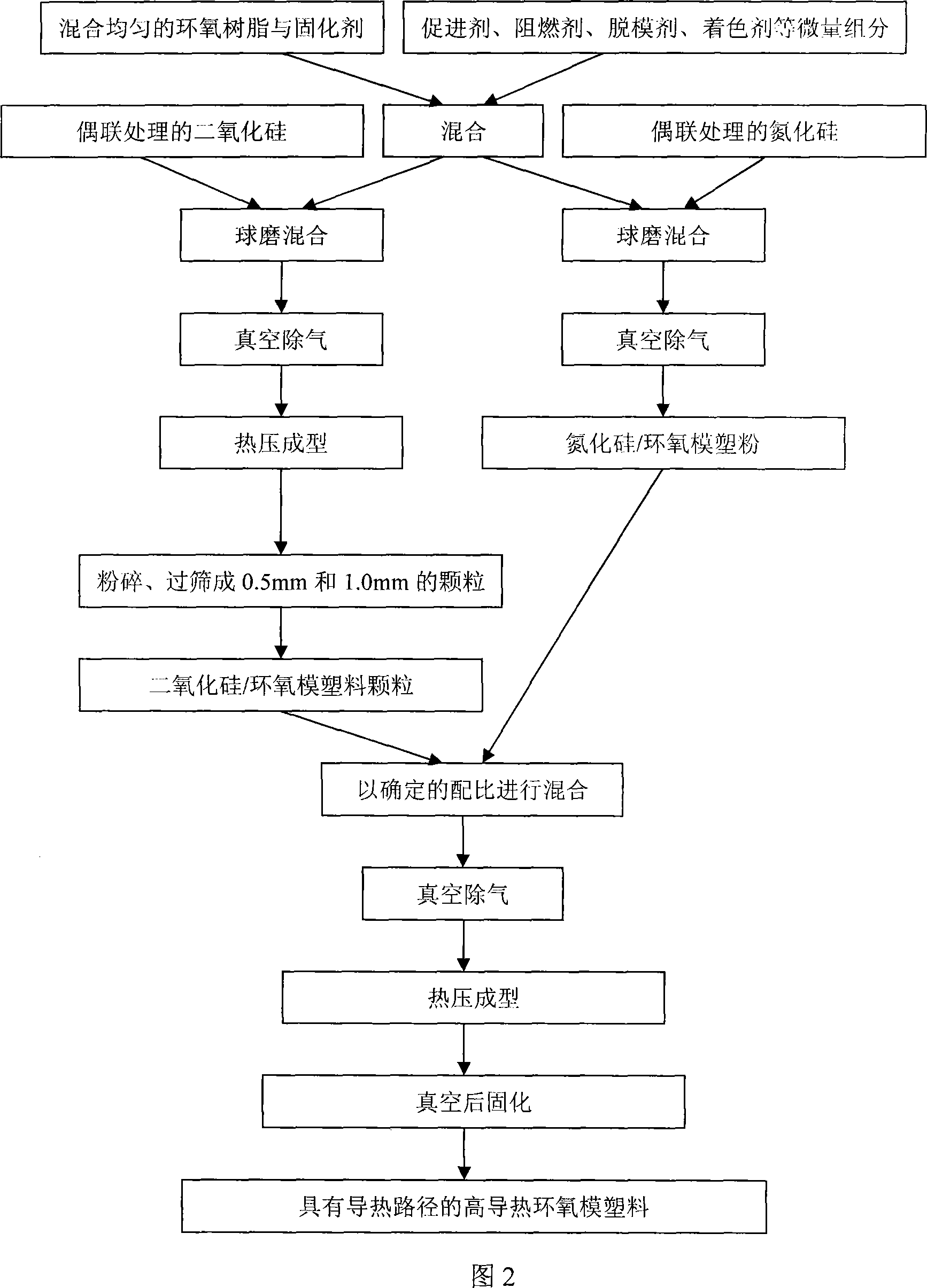

[0046] Step 4: Mix 30 parts of silicon dioxide epoxy molding compound particles and 70 parts of silicon nitride epoxy molding powder by ball milling for 2 hours, put them in a vacuum drying oven for degassing for 1 hour after mixing, and then put the mixture Hot press at 175°C and 100MPa for 5 minutes, put it into a vacuum drying oven after cooling, and post-cure at 175°C for 4 hours. After cooling, a silicon nitride epoxy molding compound sample filled with silica epoxy molding compound particles was obtained. The product properties are shown in Table 1, and the preparation process is shown in Figure 2.

example 3

[0048] Step 1: Exactly the same as Step 1 of Comparative Example 1.

[0049] Step 2: Exactly the same as Step 3 of Comparative Example 1.

[0050] Step 3: Use the molding powder prepared in step 2 to make low thermal conductivity molding particles.

[0051] Step 4: Mix 50 parts of silicon dioxide epoxy molding compound particles and 50 parts of silicon nitride epoxy molding powder by ball milling for 2 hours, put them in a vacuum drying oven for degassing for 1 hour after mixing, and then put the mixture Hot press at 175°C and 100MPa for 5 minutes, put it into a vacuum drying oven after cooling, and post-cure at 175°C for 4 hours. After cooling, a silicon nitride epoxy molding compound sample filled with silica epoxy molding compound particles was obtained. The product properties are shown in Table 1, and the preparation process is shown in Figure 2.

[0052] Table 1: Sample properties of each embodiment

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com