Resorbable implantable devices

An implantable, silk fibroin technology, used in medical science, prosthesis, surgery, etc., can solve the problems of slow degradation of polyglycolic acid, increased risk of adverse reactions, and undetermined prion disease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

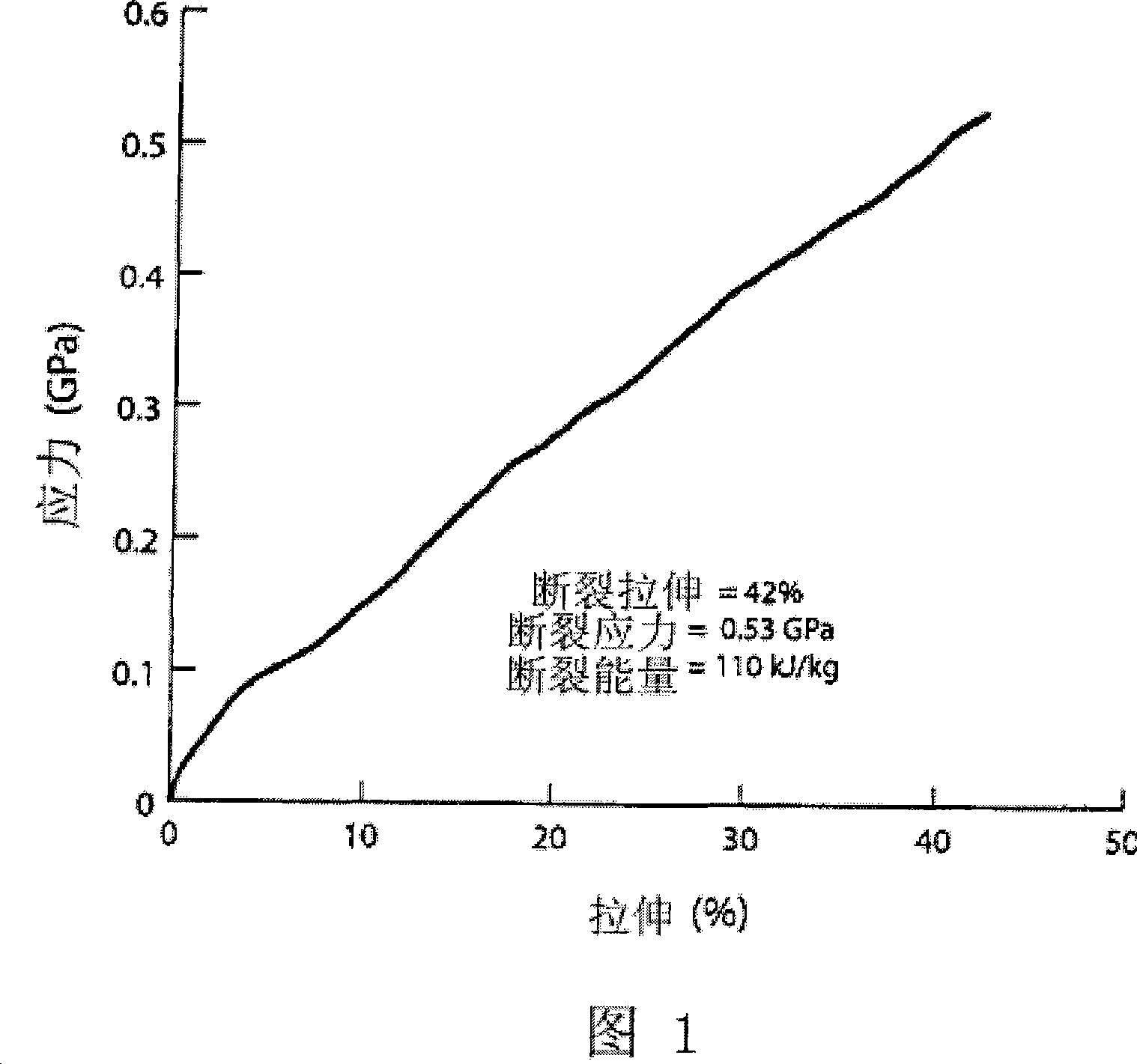

[0077] Example 1: Enhancement of suture strength and toughness by treatment with hot citric acid

[0078] The tensile properties of silk fibroin and sutures prepared from silk fibroin can be significantly improved by treatment with hot citric acid as follows: A. Prepare a 5% citric acid solution and adjust to pH 5.5 with concentrated or weak sodium hydroxide. Silk fibroin was treated with citric acid solution at 80°C for 1 hour. Silk fibroin was removed from the citric acid solution and rinsed thoroughly with distilled water (3*30 min) and then air dried.

[0079] The treatment was found to increase critical tensile strength by approximately 5% and increase elongation by 10-15% as measured on an Instron mechanical tester as described below.

[0080] Therefore, this treatment greatly increases the toughness of silk fibroin and sutures made of silk fibroin.

Embodiment 2

[0081] Example 2: Prolongation of suture absorption time

[0082] Process the silk fibroin of the present invention with formic acid and methanol to increase its resorption time in the following manner before or after the silk protein excipient is added: the silk fibroin (or the suture thread made of silk fibroin) is immersed in a 10-95 % formic acid solution or exposed to the vapor of formic acid solution at room temperature for 1-5 hours. The silk fibroin was washed and allowed to air dry. This treatment resulted in an increased degree of silk fibroin crystallinity, as determined by X-ray crystallography or by measuring the glass transition temperature of thoroughly dried fibers by various scanning calorimetry methods.

[0083] A further increase in crystallinity was achieved by additionally immersing the silk fibroin in a 30-100% methanol solution or exposing the silk fibroin to the vapors of this solution for 1 hour. The silk fibroin was air dried after washing. Better ...

Embodiment 3

[0087] Example 3: Binding peroxidase to silk protein

[0088] 1.16 mg horseradish peroxidase (HRP) was dissolved in 4 ml deionized water and 0.8 ml sodium periodate. The mixture was stirred at room temperature for 20 minutes. The mixture was added 6 drops of ethylene glycol and stirred at room temperature for 5 minutes to form an oxygenated HRP solution.

[0089] 2.25 mg silk fibroin was soaked in distilled water for 30 minutes and the pH was adjusted to 9.0-9.5 with 1M sodium carbonate solution. Oxygenated HRP solution was added and the resulting solution was stirred at room temperature for 2 hours.

[0090] 3. 0.4 ml of freshly prepared 0.4% w / v sodium tetraborate solution was added to the resulting solution, and then silk fibroin was incubated in the solution for 2 hours at 2-8°C.

[0091] 4. Finally the silk fibroin is washed thoroughly and air dried.

[0092] The efficiency of the binding reaction can be assessed by peroxidase staining with diaminobenzidine. An unbou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com