Polyolefin composite thin film and preparation and application thereof

A polyolefin, composite membrane technology, applied in chemical instruments and methods, synthetic resin layered products, structural parts, etc., can solve problems such as the inability to effectively improve the safety of lithium-ion batteries, and improve thermal safety and cyclability. , the effect of improving strength and improving thermal safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] According to the preparation method of the polyolefin composite film provided by the present invention, although it can be obtained by directly laminating the above polyolefin layer and the heat-resistant layer, preferably, according to a preferred embodiment of the present invention, the polyolefin composite film The preparation method of the film includes preparing a heat-resistant layer, and then coating a polyolefin substrate solution forming a polyolefin layer on the heat-resistant layer, drying and forming a film to obtain a composite heat-resistant layer loaded with a polyolefin film, and then applying the composite heat-resistant layer The hot layer is immersed in the extractant to extract the solvent in the polyolefin film to obtain a composite heat-resistant layer with air holes, which is the polyolefin composite film provided by the invention . The extractant is a solvent capable of dissolving the polyolefin resin solution but not dissolving the polyolefin su...

Embodiment 1

[0053] This example is used to illustrate the polyolefin composite film provided by the present invention and its preparation method.

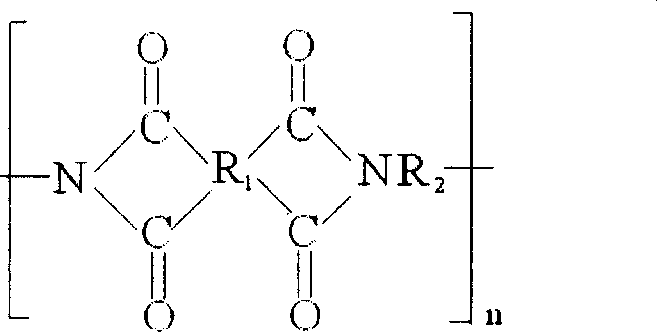

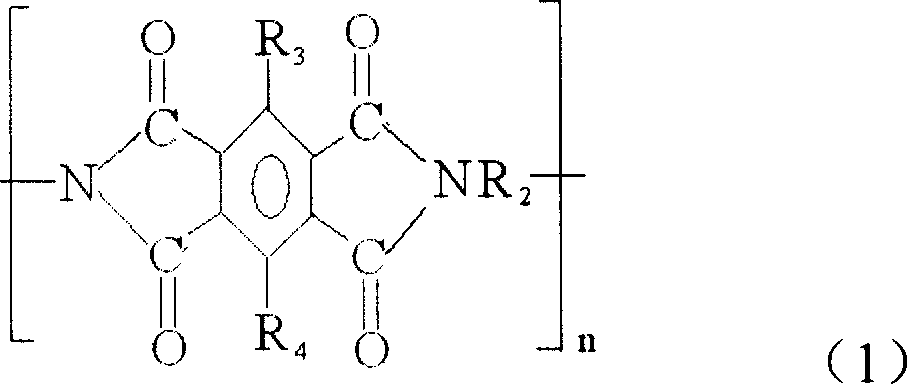

[0054] 10.2 parts by weight of a mixture (molar ratio 1:1) consisting of benzophenone tetraacid dianhydride (analytical pure) and diaminodiphenyl ether (analytical pure), 1.8 parts by weight of polyether polyurethane with a weight average molecular weight of 22000 And 82 parts by weight of N-methylpyrrolidone (NMP) stirred and reacted for 10 hours at 10°C to obtain the intrinsic viscosity η int =220 ml / g (measurement conditions: Ubbelohde viscometer, constant temperature 30°C, solution diluted to a solid content of 0.005 g / ml) viscous polyamic acid solution. Then apply the above solution evenly on a clean and smooth glass plate with a QTG type film applicator, put it in a 90°C drying oven to dry for 1 hour, and then program the temperature to 300°C for imidization for 1 hour , to obtain a polyimide film, and then raise the temperature to 350°...

Embodiment 2

[0057] This example is used to illustrate the polyolefin composite film provided by the present invention and its preparation method.

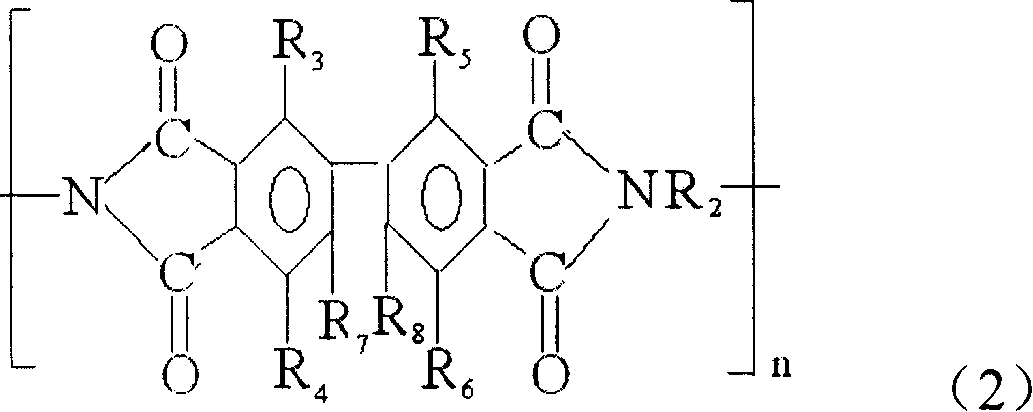

[0058] 10.2 parts by weight of a mixture (molar ratio 1:1) consisting of biphenyltetracarboxylic dianhydride (analytical pure) and p-phenylenediamine (analytical pure), 1.8 parts by weight of polymer chains containing amino groups at one end of the polymer chain with a weight average molecular weight of 18000 Polypropylene oxide and 82 parts by weight of DMAc were stirred and reacted for 10 hours at 10°C to obtain intrinsic viscosity η int =220 ml / g (measurement conditions: Ubbelohde viscometer, constant temperature 30°C, solution diluted to a solid content of 0.005 g / ml) viscous polyamic acid solution. Then apply the above solution evenly on a clean and smooth glass plate with a QTG type film applicator, put it in a 90°C drying oven to dry for 1 hour, and then program the temperature to 300°C for imidization for 1 hour , to obtain a polyimid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com