Preparation method of lithium zirconate material for absorbing carbon dioxide at high temperature

A technology of lithium zirconate and high temperature, applied in chemical instruments and methods, separation methods, lithium compounds, etc., can solve the problems of long reaction time, complicated preparation process, high energy consumption, etc., and achieve excellent absorption performance, simple process, and preparation The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Weigh ZrO with a particle size of 20nm 2 23.81 g and Li with a particle size of 0.3 μm 2 CO 3 Put 25.79g into a beaker together, add ethanol solution into the beaker, and make jelly under stirring. Treat in a microwave oven with a power of 500W for 120min, calcinate at 700°C for 6h, grind and sieve to obtain a lithium zirconate material with an average particle size of 2.4μm. The synthesized lithium zirconate material was heated at 500 °C in 20% CO 2 (80% air) at a constant temperature for a period of time, and the absorption capacity reaches 19.28wt% after the absorption equilibrium is reached.

Embodiment 2

[0013] Weigh ZrO with a particle size of 120nm 2 25.41g and Li with a particle size of 0.3um 2 CO 3 Put 22.53g into a beaker together, add methanol and ethanol mixed solution into the beaker, and make a jelly under stirring. Treat in a microwave oven with a power of 2500W for 10min, calcinate at 550°C for 6h, grind and sieve to obtain a lithium zirconate material with an average particle size of 4.1μm. The synthesized lithium zirconate material was heated at 500 °C in 20% CO 2 (80% air) at a constant temperature for a period of time, and the absorption capacity reaches 20.67wt% after the absorption equilibrium is reached.

Embodiment 3

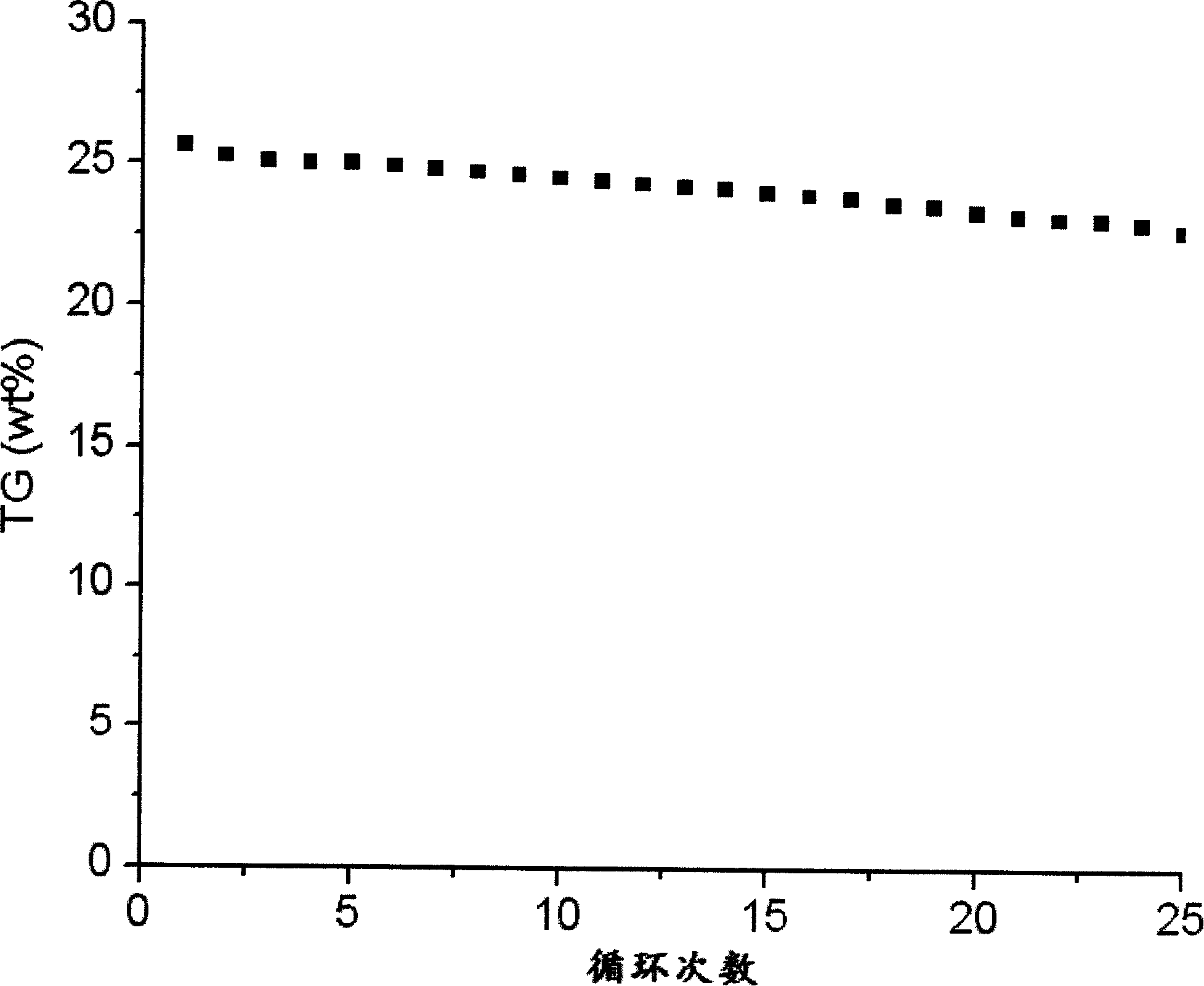

[0015] Weigh ZrO with a particle size of 100nm 2 27.21g and Li with a particle size of 0.3um 2 CO 3 16.68g were put into a beaker together, and a mixed solution of ethanol and formic acid was added to the beaker, and a small amount of acetic acid and acetone were added, and a jelly was formed under stirring. Treat in a microwave oven with a power of 1800W for 30 minutes, calcinate at 700°C for 2h, grind and sieve to obtain a lithium zirconate material with an average particle size of 3.3μm. The synthesized lithium zirconate material was heated at 500 °C in 20% CO 2 (80% air) at a constant temperature for a period of time, and the absorption capacity reaches 25.61wt% after the absorption equilibrium is reached. At 500°C, 20% CO 2 (80% air) at a constant temperature for 3 hours, and at a constant temperature of 700°C for 1 hour in an air atmosphere. Lithium zirconate absorbs CO under this test procedure. 2 After 25 absorption cycles, the absorption capacity decay rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com