Method for producing selenide and telluride nano-material with composite base metal hydroxide solvent

A hydroxide and nanomaterial technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problem of impure mixing of products, and achieve the effects of easy monitoring and control, simple operation procedures, and few controllable parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

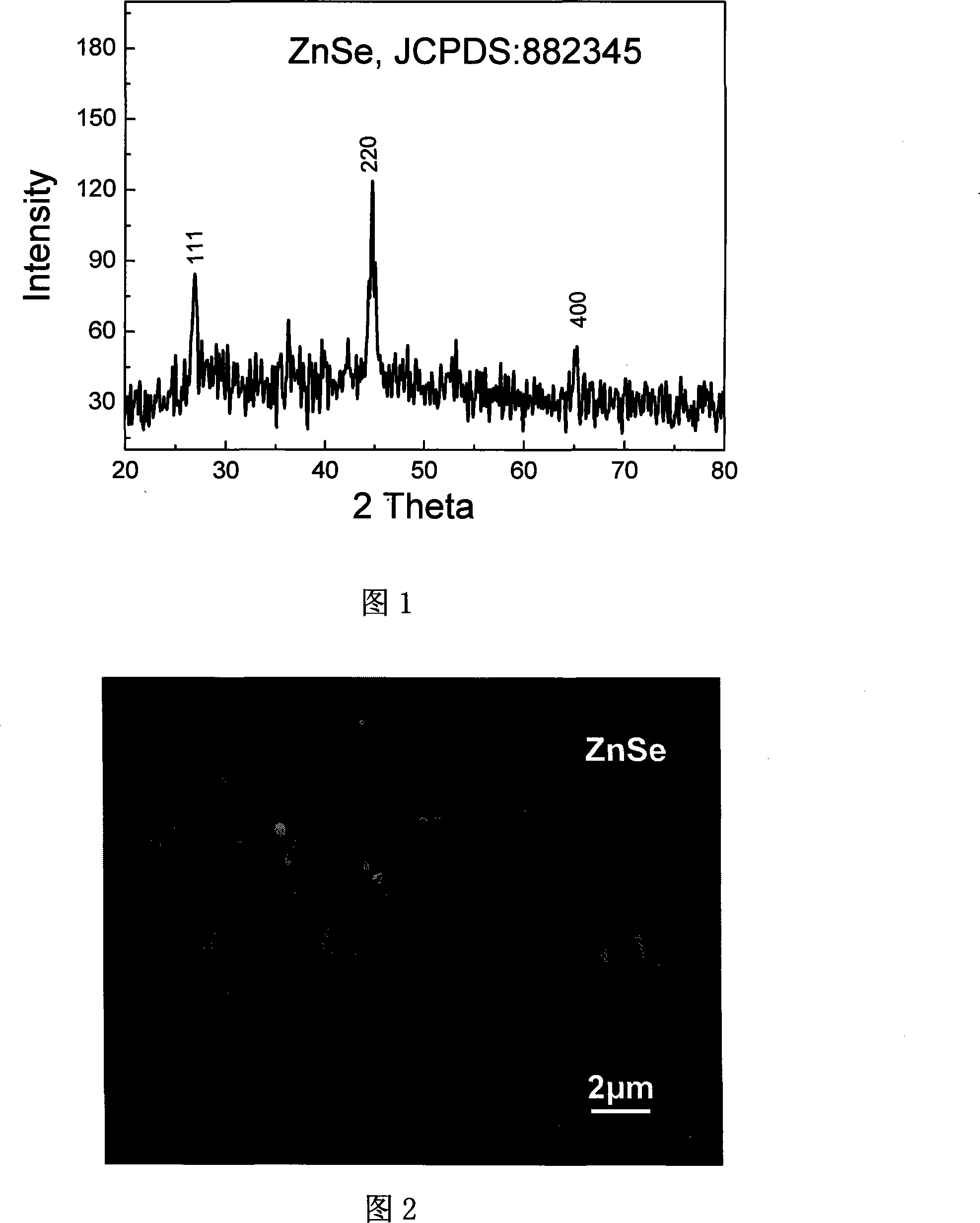

[0032] Concrete synthetic method of zinc selenide nanometer material

[0033] Zinc nitrate Zn(NO 3 ) 2 ·6H 2 O, selenium powder, hydrazine hydrate, NaOH, KOH, the specific operation steps are as follows:

[0034] Step 1, preparing a reaction solvent, weighing and mixing KOH=57% and NaOH=43% by weight as the reaction solvent.

[0035] Step 2, prepare reaction raw material, prepare zinc nitrate Zn(NO 3 ) 2 ·6H 2 O weight percentage=67.28%, the weight percentage=17.78% of selenium powder, the weight percentage=14.94% of hydrazine hydrate, weigh as reactant. The weight percentage of reactant to reactant+reaction solvent is 8.99%.

[0036] Step 3, heat the reaction, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, and then cover the polytetrafluoroethylene container and put it into a constant temperature horse with a temperature of 200 ° C. Furnace. After the reaction vessel i...

Embodiment 2

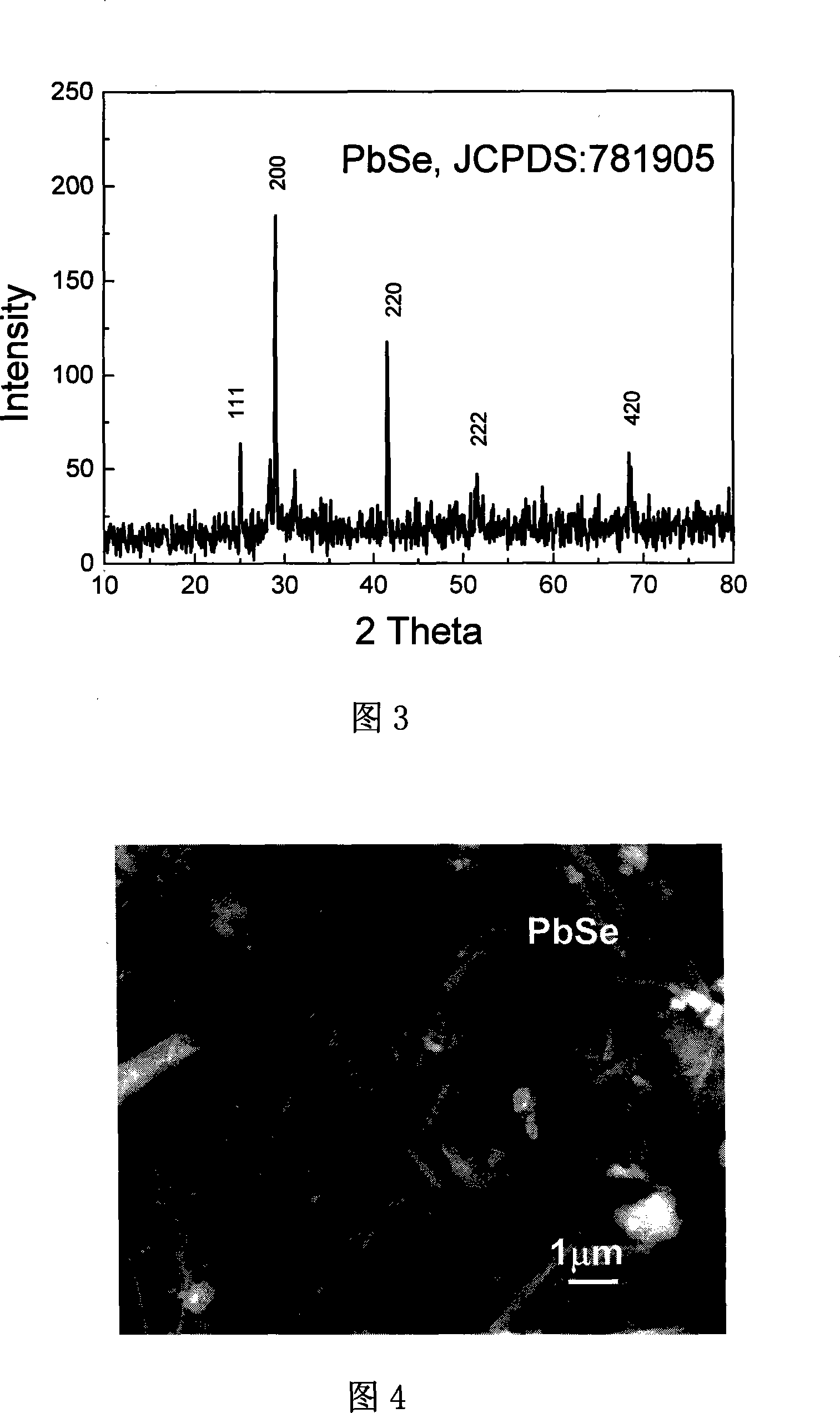

[0041] Concrete synthetic method of lead selenide nanomaterial

[0042] Lead nitrate Pb(NO 3 ) 2 , selenium powder, hydrazine hydrate, NaOH, KOH, the specific operation steps are as follows:

[0043] Step 1, preparing a reaction solvent, weighing and mixing KOH=57% and NaOH=43% by weight as the reaction solvent.

[0044] Step 2, prepare reaction raw material, prepare lead nitrate Pb(NO 3 ) 2 Weight percentage=69.26%, the weight percentage of selenium powder=16.52%, the weight percentage of hydrazine hydrate=14.22%, weighed as reactant. The weight percentage of reactants to reactants+reaction solvent was 9.61%.

[0045]Step 3, heat the reaction, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, and then cover the polytetrafluoroethylene container and put it into a constant temperature horse with a temperature of 200 ° C. Furnace. After the reaction vessel is kept warm in the ...

Embodiment 3

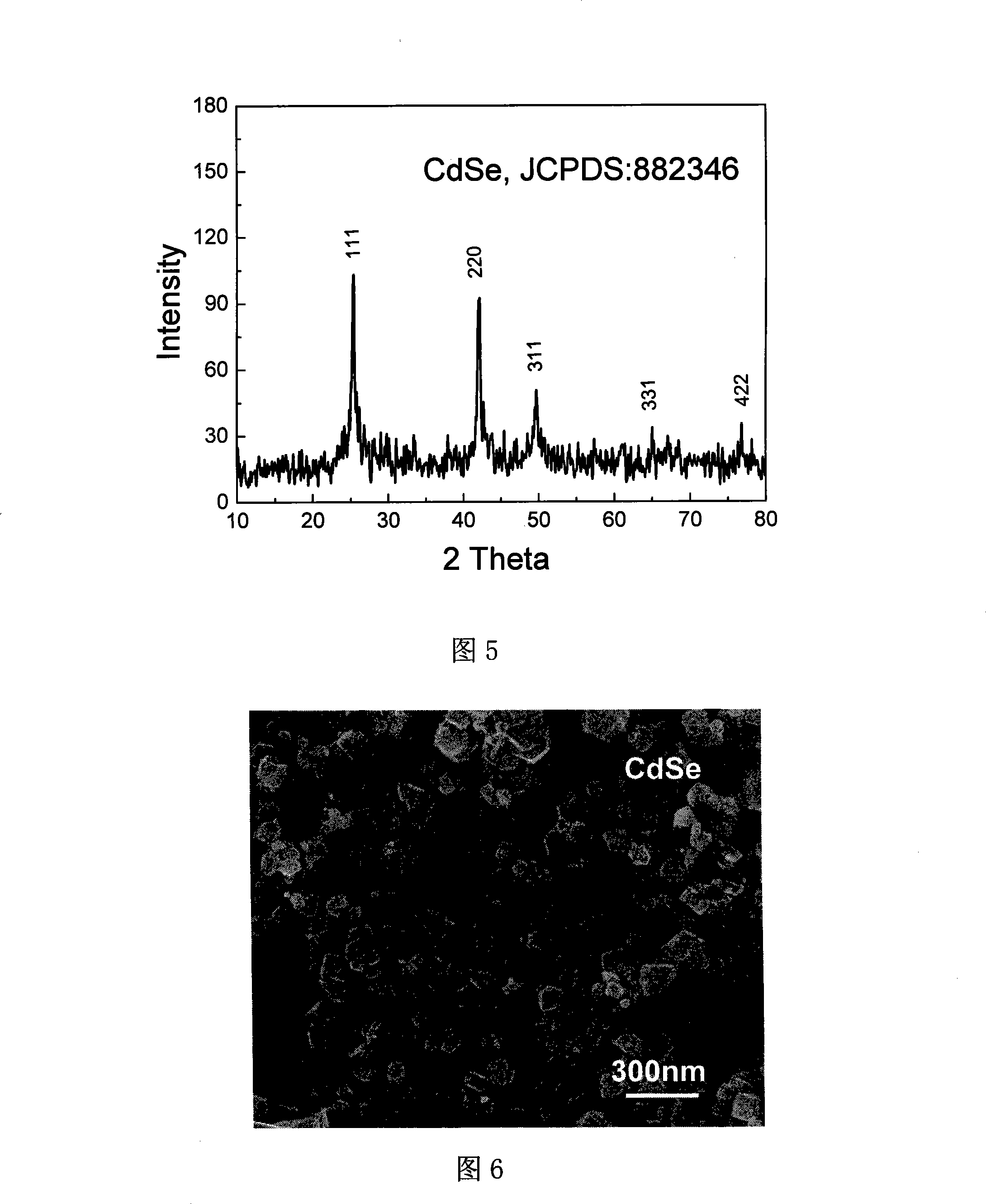

[0050] Concrete synthetic method of cadmium selenide nanomaterial

[0051] Cadmium nitrate Cd(NO 3 ) 2 4H 2 O, selenium powder, hydrazine hydrate, NaOH, KOH, the specific operation steps are as follows:

[0052] Step 1, preparing a reaction solvent, weighing and mixing KOH=57% and NaOH=43% by weight as the reaction solvent.

[0053] Step 2, prepare reaction raw material, prepare cadmium nitrate Cd (NO 3 ) 2 4H 2 O weight percentage=62.05%, the weight percentage=20.39% of selenium powder, the weight percentage=17.56% of hydrazine hydrate, weigh as reactant. The weight percent of reactants to reactants+reaction solvent was 7.93%.

[0054] Step 3, heat the reaction, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, and then cover the polytetrafluoroethylene container and put it into a constant temperature horse with a temperature of 200 ° C. Furnace. After the reaction vessel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com