Membrana for lead ion selection electrode with poly-m-phenylenediamine as carrier, production method and uses thereof

A technology of poly-m-phenylenediamine and selective electrodes, which is applied in the direction of material analysis, instruments, and analysis materials through electromagnetic means, can solve the problems of cumbersome carrier synthesis and difficulty in popularization, and achieve the benefits of popularization and application, low cost and low price. The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of carrier polym-phenylenediamine

[0039] The carrier poly-m-phenylenediamine was prepared by chemical oxidation synthesis. Dissolve 8.651 g (0.08 mol) of m-diamine monomer in 100 mL of distilled water, ultrasonicate for 3 to 5 minutes to promote its full dissolution, place in a constant temperature water bath at 30°C, and equilibrate for half an hour. Dissolve 0.08 mol of ammonium persulfate oxidizing agent in 100 mL of distilled water and maintain it at 30°C. Add the ammonium persulfate solution dropwise to the monomer solution at a rate of 1 drop / 3 seconds, and start timing at the same time. After the dropwise addition, the reaction was continued for a total of 24h. After the completion of the reaction, filter with suction, and wash the product in the funnel with distilled water until it is washed with BaCl 2 The solution was tested to be free of sulfate ions. After washing, dry at 50°C for 3 days to obtain poly-m-diamine (PmPD).

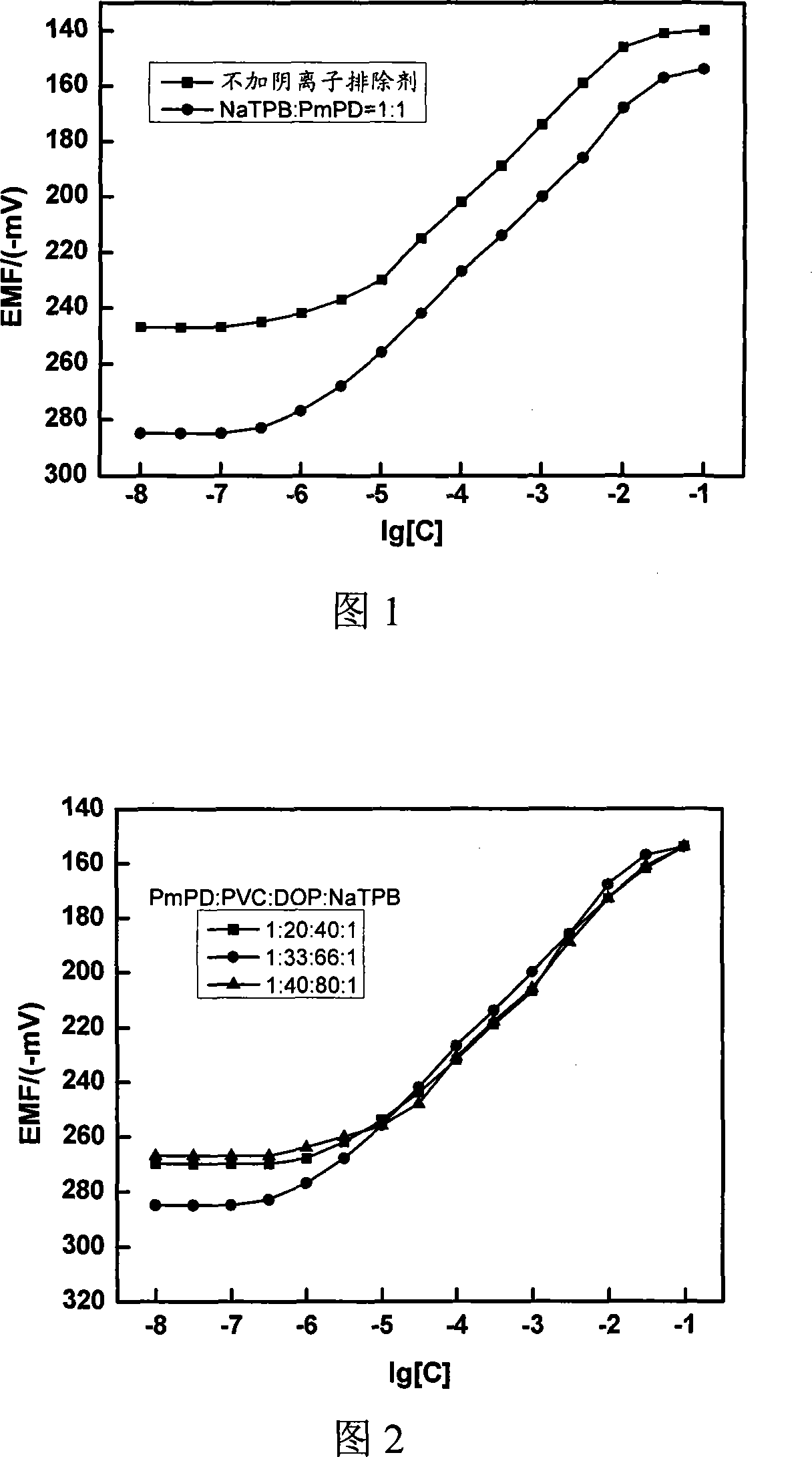

Embodiment 1

[0041] Weigh 6.06 mg of poly-m-phenylenediamine, 200 mg of PVC, and 400 mg of DOP (dioctyl phthalate), add these four reagents into a beaker, and add 5 mL of tetrahydrofuran to completely dissolve PVC, and sonicate in an ultrasonic instrument for 30 minutes Make the carrier better dispersed. Stir at a constant temperature at 25°C until it becomes viscous, then pour the mixed solution on a flat-bottomed glass, and let it stand for 24 hours. After the tetrahydrofuran is completely volatilized, a film with a weight ratio of PmPD:PVC:DOP=1:33:66 is obtained.

Embodiment 2

[0043] Weigh 10 mg of poly-m-phenylenediamine, 200 mg of PVC, 400 mg of DOP (dioctyl phthalate), and 10 mg of anion removing agent NaTPB. These four reagents were added to a beaker, and 5 mL of tetrahydrofuran was added to dissolve the PVC completely, and the carrier was sonicated for 30 minutes in an ultrasonic instrument to better disperse the carrier. Stir at a constant temperature at 25°C until it becomes viscous, then pour the mixed solution on a flat-bottomed glass, and let it stand for 24 hours. After the tetrahydrofuran is completely volatilized, the weight ratio of PmPD:PVC:DOP:NaTPB=1:20:40:1 is obtained. film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com