Ultra-fine light calcium carbonate slurry and production method thereof

A technology of light calcium carbonate and ultrafine calcium carbonate, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of low dispersion efficiency, high adhesion of filter cake, poor viscosity stability of slurry, etc. problem, to achieve the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Get the calcium carbonate filter cake 150kg that weight solid content is 53%, particle average particle size is 0.12 μ m, this filter cake is placed in horizontal ribbon mixer, adds:

[0043] 1.59kg is the aqueous solution of the acrylic acid polymer dispersant shown in formula (A), and its mass content is 40%;

[0044] 0.159kg propylene glycol;

[0045] 2.38kgHX-5010;

[0046] and 2.88kg of water;

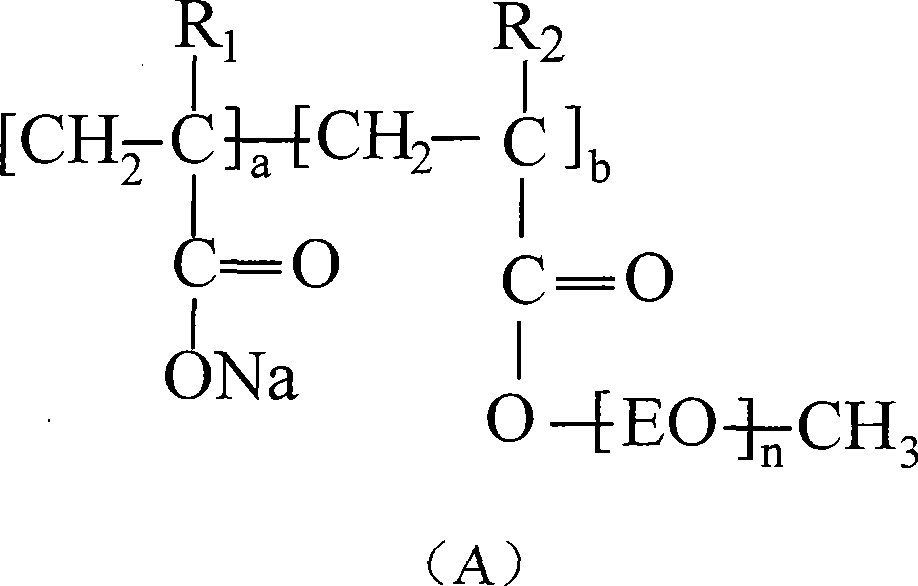

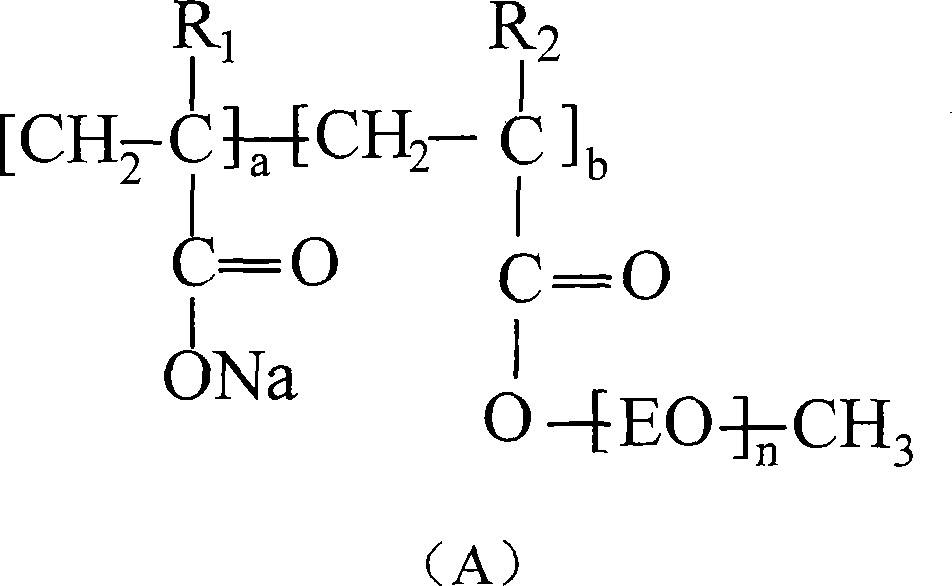

[0047] After premixing for 20 minutes, the slurry after the premixing is then sheared and dispersed by a pipeline type high-shear emulsification pump to obtain the viscosity described in the present invention as 154mPa.s (the test of slurry viscosity adopts NDJ-79 type rotary Viscometer test, with the rotor of 10 times, hereinafter the same) solid content is the superfine calcium carbonate water-based slurry of 52%. Said acrylic acid copolymer (A), R 1 for H, R 2 It is H, n=15, a=3, a / b=1, and the average weight average molecular weight is 20000.

Embodiment 2

[0049] Take 150 kg of calcium carbonate filter cake with a weight solid content of 70% and an average particle size of 0.81 μm. After placing the filter cake in a gravity-free twin-shaft paddle mixer, add CH-10B 3.15 kg, butanediol 2.10 kg and BYK-021 0.21kg, after premixing for 30 minutes, the premixed slurry is sheared and dispersed by a pipeline type high-shear emulsification pump, and the viscosity of the present invention is 96mPa.s and the solid content is 70%. Ultrafine calcium carbonate water-based slurry.

[0050] CH-10B is a CH series hyperdispersant product of Shanghai Sanzheng Polymer Materials Co., Ltd.

Embodiment 3

[0052]Get the calcium carbonate filter cake 150kg that solid content is 55%, particle average particle diameter is 80nm, after this filter cake horizontal ribbon mixer, add CH-18C 1.65kg, butanediol 2.06kg and AntifoamMR10500.16kg and The mixed solution of 5.67kg of water, after premixing for 15 minutes, the slurry after premixing is sheared and dispersed by a pipeline type high-shear emulsification pump, and the viscosity described in the present invention is 107mPa.s and the solid content is 53%. Nano calcium carbonate aqueous slurry. CH-18C is a CH series hyperdispersant product of Shanghai Sanzheng Polymer Materials Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com