Supported PtRu alloy catalyst and preparing method thereof

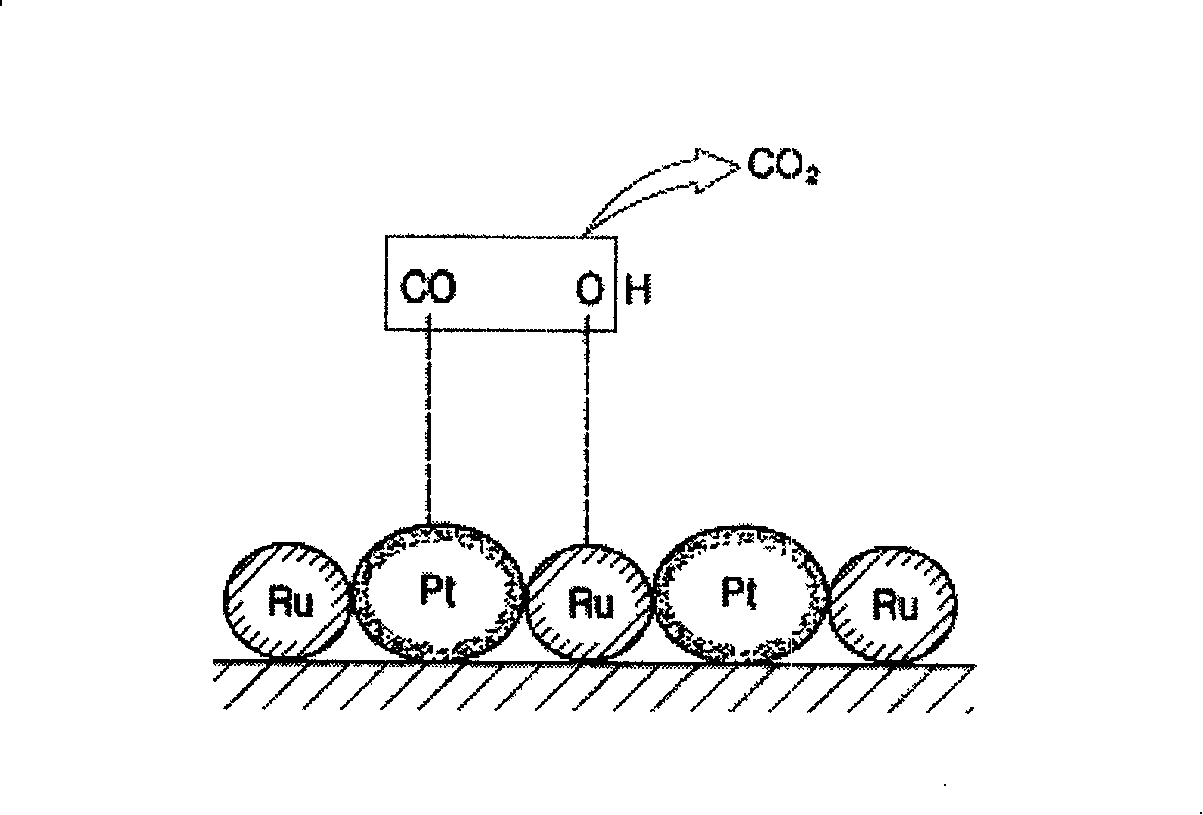

An alloy catalyst and a supported technology are applied in the field of supported PtRu alloy catalyst and its preparation, which can solve problems such as large environmental impact, achieve the effects of uniform distribution, improve crystallinity, and improve the ability to resist CO poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

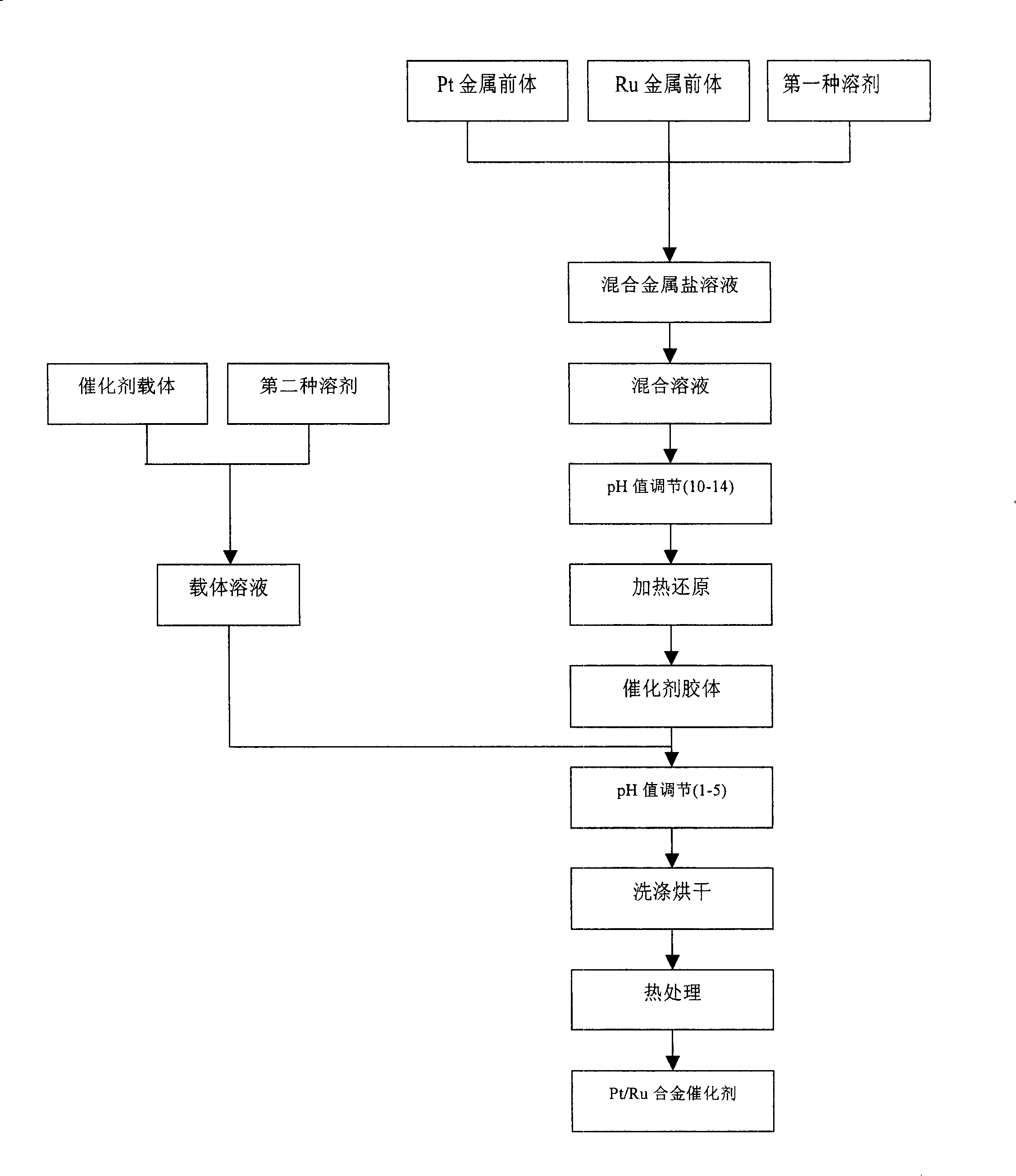

Method used

Image

Examples

Embodiment 1

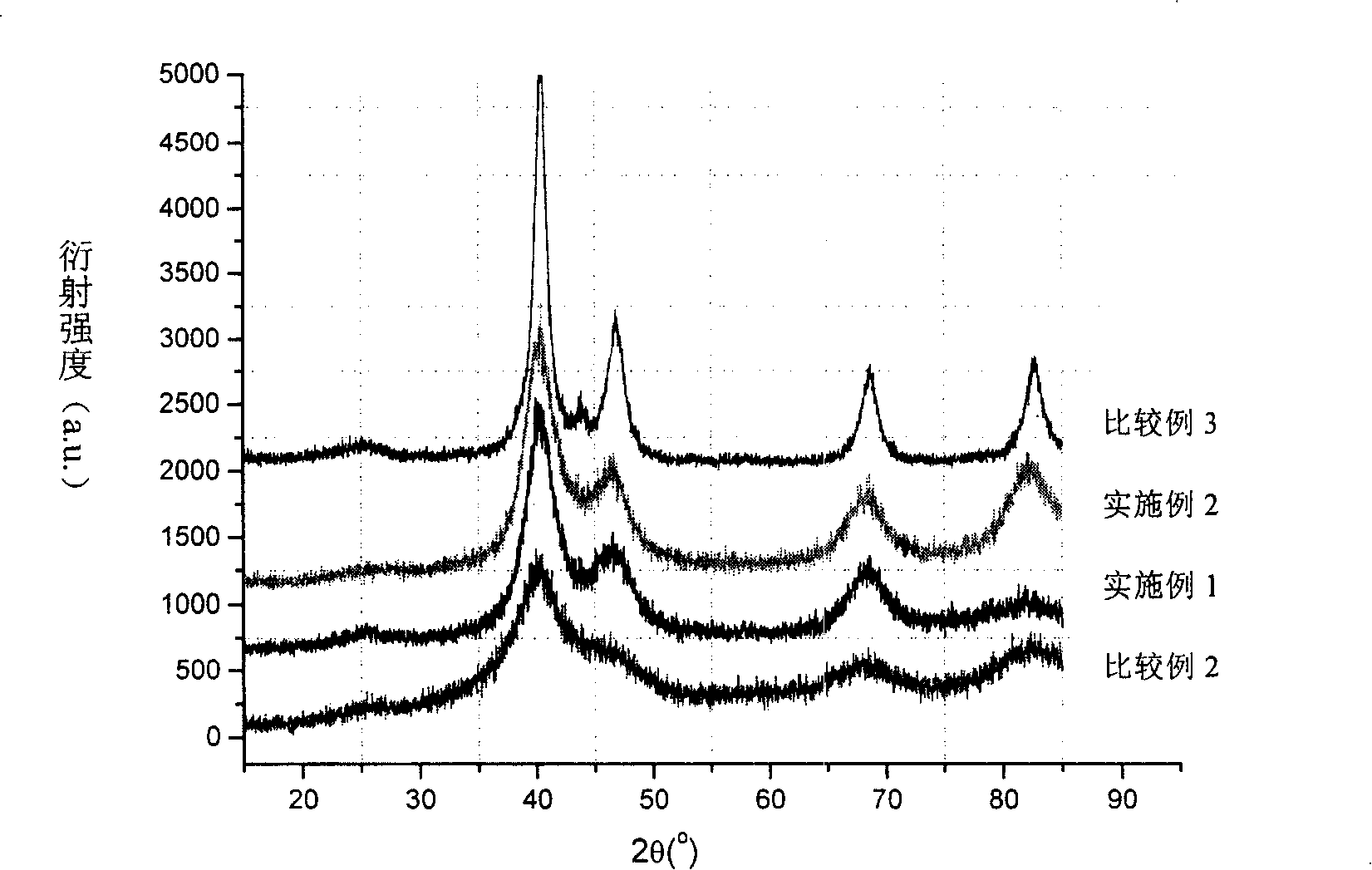

[0043] 1 g of chloroplatinic acid hydrate (H 2 PtCl6 xH 2 O) (37% by mass of metal Pt) and 0.5g of ruthenium trichloride hydrate (37% by mass of metal Ru) were added to 25ml of ethylene glycol, and stirred evenly to form a mixed metal solution. Add 0.370g of carbon black into 100g of ethylene glycol, stir to disperse evenly, and form a carrier solution. NaOH solution was added dropwise to the mixed metal solution to adjust the pH value of the solution to 13. Put the above solution in an oil bath, raise the temperature to 180°C and keep it for 30 minutes, then lower it to 170°C and keep it for 3 hours, the metal is reduced and a black catalyst colloid solution is formed. Add the carrier solution to the catalyst colloidal solution, mix well, and adjust the pH of the solution to 3 with hydrochloric acid, then filter, wash with deionized water, and dry at 80°C in vacuum. The obtained catalyst was treated in a tube furnace at 200° C. for 2 hours with hydrogen-argon mixed gas wit...

Embodiment 2

[0045] 1 g of chloroplatinic acid hydrate (H 2 PtCl6 xH 2 O) (37% by mass of metal Pt) and 0.5g of ruthenium trichloride hydrate (37% by mass of metal Ru) were added to 25ml of ethylene glycol, and stirred evenly to form a mixed metal solution. Add 0.140g of carbon black into 100g of ethylene glycol, stir to disperse evenly, and form a carrier solution. NaOH solution was added dropwise to the mixed metal solution to adjust the pH value of the solution to 13. Put the above solution in an oil bath, raise the temperature to 180°C and keep it for 30 minutes, then lower it to 170°C and keep it for 3 hours, the metal is reduced and a black catalyst colloid solution is formed. Add the carrier solution to the catalyst colloidal solution, mix well, and adjust the pH of the solution to 3 with hydrochloric acid, then filter, wash with deionized water, and dry at 80°C in vacuum. The obtained catalyst was treated in a tube furnace at 200° C. for 2 hours with hydrogen-argon mixed gas wit...

Embodiment 3

[0047] The catalyst preparation process is the same as in Example 1. The heat treatment condition is to treat at 200° C. for 30 minutes in a hydrogen-argon mixed gas with a hydrogen fraction of 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com