Pichia yeast genetic engineering bacteria for producing glutathione and recombinant plasmid used for constructing the same

A technology of genetically engineered bacteria and recombinant plasmids, applied in the field of bio-fermentation to synthesize glutathione, can solve the problems of high-density cultivation of brewer's yeast, reduce fermentation quality, increase fermentation cost, etc., to facilitate large-scale industrial production, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The acquisition and preservation of embodiment 1 brewer's yeast gshI and gshII genes

[0021] 1) Primers were designed with the GSH1 and GSH2 gene sequences of S. cerevisiae from the NCBI GenBank database. The 5' ends of the upstream primers in the two pairs of primers both contained Kozark sequences and added a Cla I restriction site (underlined) at the 5' ends. ), a Not I restriction site (underlined) is added to the 5' end of the downstream primer; the gshI upstream and downstream primers are respectively:

[0022] CC ATCGAT ACCATGGGACTCTTAGCTTTG

[0023] G CGGCCG CTTAACATTTGCTTTCTAT,

[0024] The gshII upstream and downstream primers are:

[0025] CC ATCGAT ACCATGGCACACTATCCA

[0026] G CGGCCG CCCTAGTAAAGAATAATACTG.

[0027] 2) Obtain gshI and gshII by PCR

[0028] Use Saccharomyces cerevisiae y10 as a template and amplify the product with Taq enzyme. The PCR conditions are: ① 97°C for 5 minutes, ② Pause, ③ 94°C for 30 seconds, ④ 58°C for 1 minute, ⑤ 72...

Embodiment 2

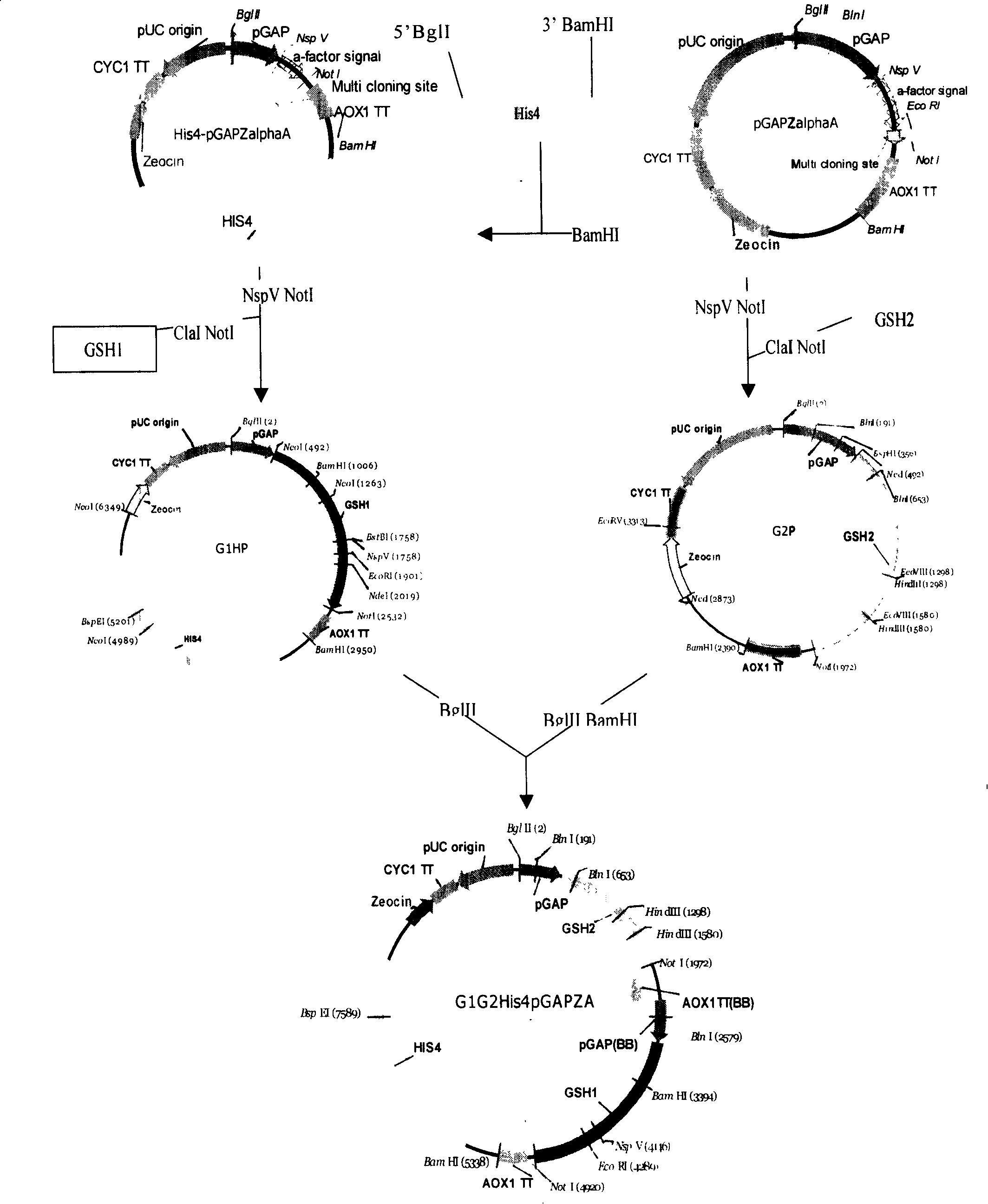

[0034] Example 2 Construction of plasmid His4-pGAPZαA

[0035] 1) Design primers to obtain a His4-containing fragment by PCR using plasmid pAO815 as a template. Its upstream primer starts from the plasmid BamH I site (underlined) and adds a protective base at the 5' end; the downstream primer 5' end adds the restriction site Bgl II (underlined) with the same tail as BamH I, and adds The upper protective base; the upper and lower primers are respectively:

[0036] GC GGATCC TAATGCGGTAGTTTATCACAGTTA and

[0037] GA AGATCT TCATGACATTTCCCTTGCTACCTG.

[0038] 2) The His4 fragment was obtained by PCR amplification with Taq enzyme [TaKaRa]. PCR conditions: ①97°C for 5 min, ②pause, ③94°C for 30 sec, ④59.6°C for 1 min, ⑤72°C for 3.5 min, ⑥repeat ③~⑤ for a total of 29 cycles, ⑦72°C for 10 min, ⑧4°C hold.

[0039] 3) The PCR product was digested with BamH I and Bgl II and recovered from the gel, pGAPZαA was digested with BamHI and the fragment was recovered from the gel;

[0040...

Embodiment 3

[0043] Construction of embodiment 3 plasmid G2P

[0044] 1) PMD18T-gshII was double-digested with Cla I and Not I to recover the gshII-containing fragment gshII / ClaI Not I; a large number of NspV and Not I double-digested plasmid pGAPZαA was recovered to recover a large fragment pGAPZαA / NspVNot I;

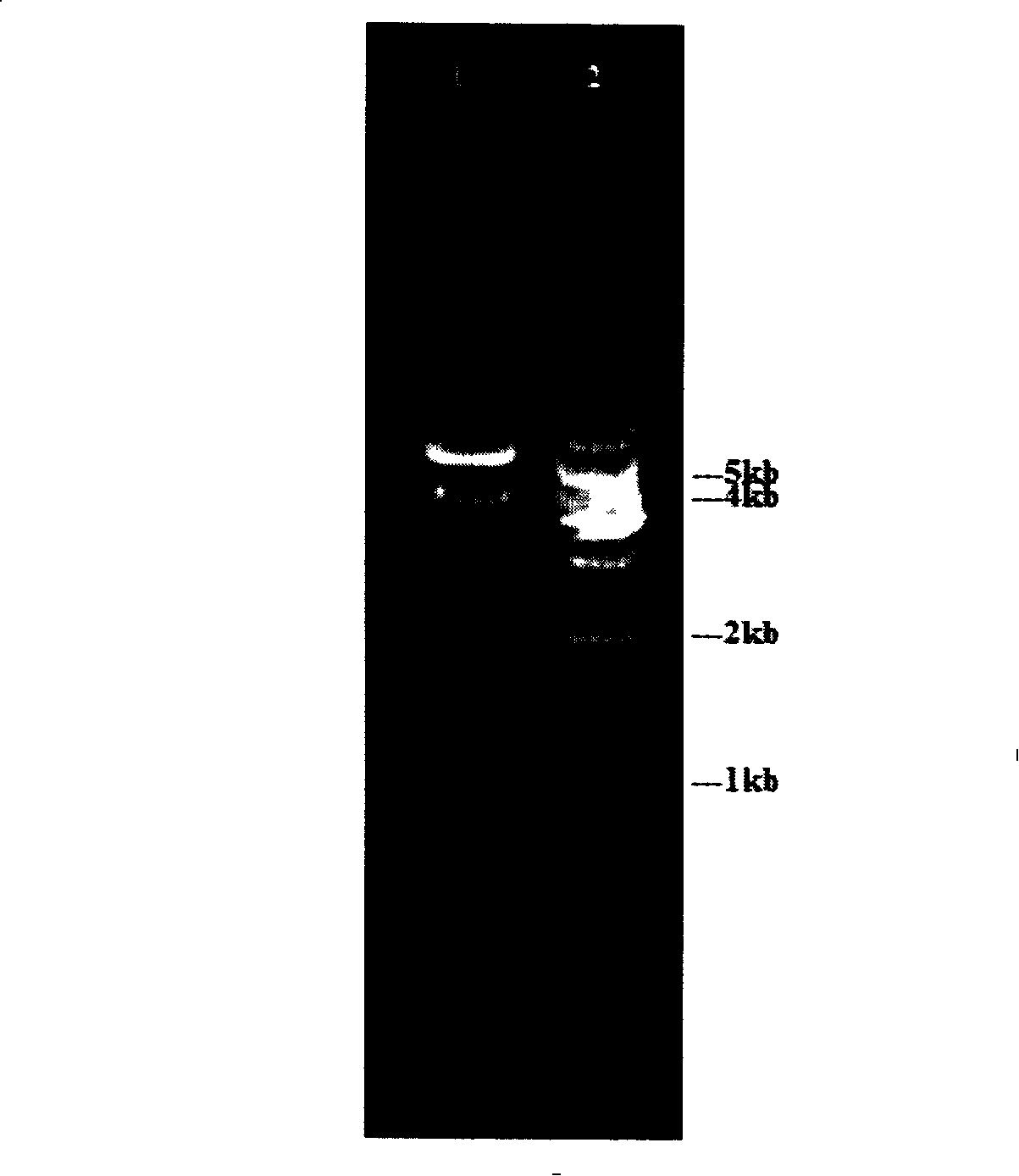

[0045] 2) Ligate the above-mentioned fragment gshII / ClaINotI with pGAPZαA / NspVNotI and transform it into E.coliDH5α (for the transformation method, refer to the purchased competent cell manual), and finally spread the transformed bacteria solution on 25 μg / ml Zeocin TM On a low-salt LB agar plate, wait for a single colony to form at 37°C for 12-16 hours, extract the plasmid, and identify it by single-enzyme digestion with Bln I. The electrophoresis diagram of the correct plasmid restriction enzyme digestion shows two bands of 462bp and 3846bp to preserve the positive bacterial glycerol tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com