Hydrophilised nano finishing method for surface of keratin porous material fabric

A nano-finishing and porous material technology, which is applied in the processing of textile materials, fiber processing, textiles and papermaking, etc., can solve the problems of high cost, small processing area at one time, discomfort, etc., and achieve strength and durability, broaden the Range of application, effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] SiO with a particle size of 50 nm 2 Mix 1 part by weight of particles with 100 milliliters of deionized water, stir evenly to form a solution, adjust the pH of the obtained solution to 3 with HCl, and prepare a nano-finishing solution. Soak the wool cloth in 20:80 (volume ratio) ethanol aqueous solution for 60 minutes, take it out and soak it in the nano-finishing solution, the bath ratio is 1:80, the constant temperature water bath is 100°C, and the constant temperature treatment is 5 hours . Rinse the wool cloth treated with the above-mentioned nano-finishing solution, dry it by rolling, and then put it into an oven at 100° C. for drying.

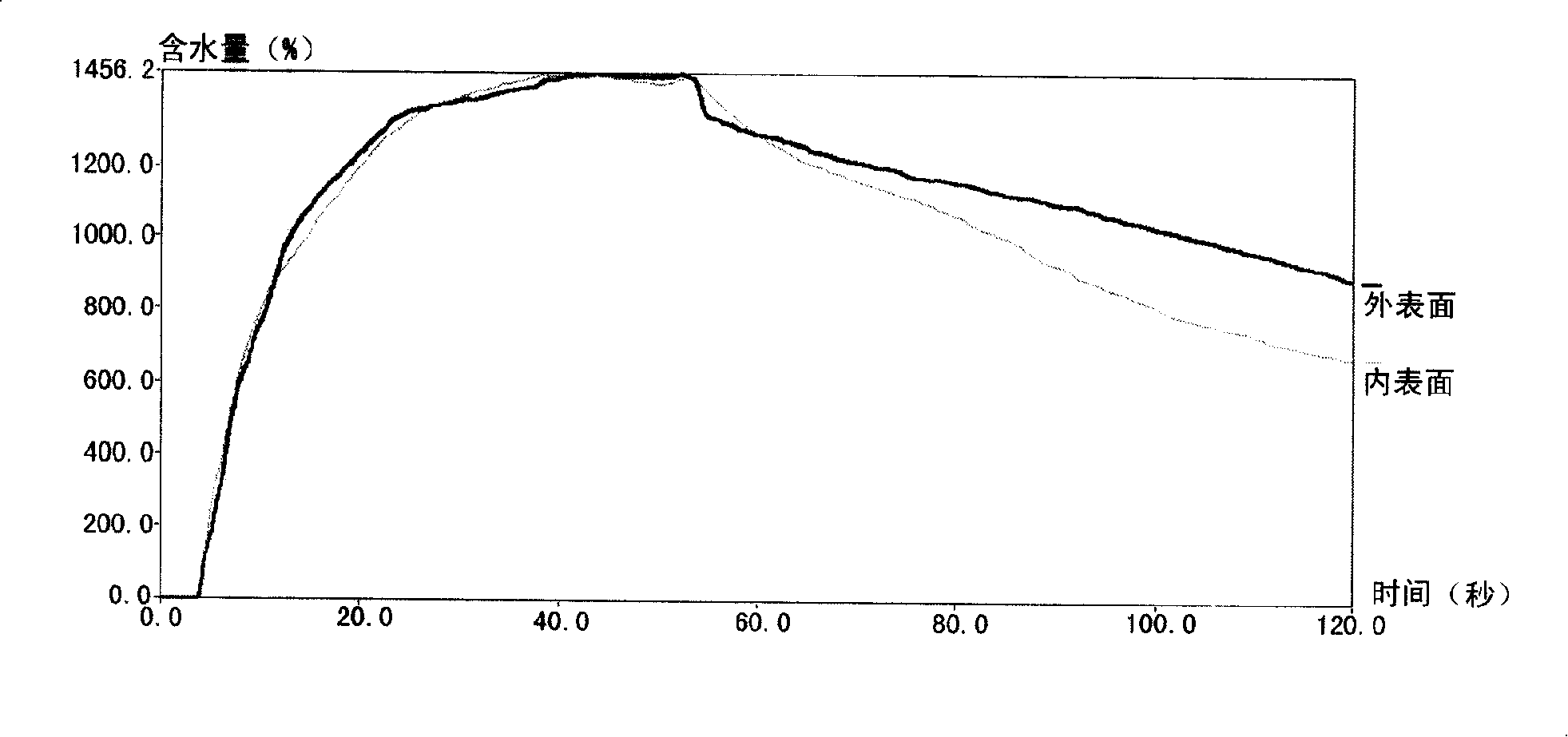

[0046] The dynamic change process of the water content on both surfaces of the wool fabric treated in Example 1 was measured by using a fabric liquid water dynamic transfer characteristic measuring instrument. For the specific measurement method, please refer to the entry-exit inspection and quarantine industry standard SN / T 1689...

Embodiment 2

[0052] SiO with a particle size of 100 nm 2 5 parts by weight are mixed with 100ml of deionized water, stirred uniformly to form a solution, the pH of the solution is adjusted to 6 with acetic acid, 5 parts by weight of silver-based antibacterial agent with the function of releasing negative ions is added, mixed evenly, and nano finishing liquid is made. Wool fabric to be treated is soaked in the aqueous ethanol solution of 20: 80 (volume ratio) for 60 minutes, then soaked in the above-mentioned nano finishing liquid, the bath ratio of fabric quality and nano finishing liquid is 1: 80, and constant temperature water bath is 100 ℃, Constant temperature treatment for 0.5 hours. Rinse the fabric treated with the above-mentioned nano-finishing solution, dry it by rolling, and then put it into an oven at 100° C. for drying.

[0053] With the measurement method described in Example 1, the dynamic change process of the water content on both surfaces of the wool fabric treated in Ex...

Embodiment 3

[0059] 15 parts by weight of sodium silicate, 8 parts by weight of ethylene-vinyl acetate and 100 ml of deionized water were evenly stirred to prepare a solution. Use HCl to adjust the pH of the solution to 5, add 5 parts by weight of a silver-based antibacterial agent, and mix evenly to prepare a nano-finishing solution. Soak woolen cloth in ethanol solution for 10 minutes, ethanol solution is 20% (volume ratio) aqueous solution, after taking it out, soak in the described nano finishing liquid, bath ratio is 1: 10, constant temperature water bath is 60 ℃, constant temperature Processed for 3 hours. Rinse the wool cloth treated with the above-mentioned nano-finishing liquid, dry it by rolling, and then put it into an oven at 120° C. for drying.

[0060] With the measurement method described in Example 1, the dynamic change process of the water content on both surfaces of the wool cloth treated in Example 3 was measured, and the results showed that the treated fabric had good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com